What is Global Chopped Strands for Thermoplastics Market?

The Global Chopped Strands for Thermoplastics Market is a specialized segment within the broader composite materials industry. Chopped strands are short lengths of glass fibers that are used to reinforce thermoplastics, which are a type of plastic material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. These chopped strands enhance the mechanical properties of thermoplastics, such as strength, durability, and resistance to impact and heat. This makes them highly desirable in various industries that require materials with superior performance characteristics. The market for these materials is driven by the increasing demand for lightweight and high-strength materials in industries such as automotive, construction, and electronics. As manufacturers seek to improve the performance and efficiency of their products, the use of chopped strands in thermoplastics is becoming more prevalent. The market is characterized by continuous innovation and development, with companies investing in research to improve the quality and performance of chopped strands. This market is also influenced by environmental regulations and the push towards sustainable materials, as chopped strands can contribute to the production of more eco-friendly products. Overall, the Global Chopped Strands for Thermoplastics Market is a dynamic and growing field with significant potential for future development.

10μm, 11μm, 13μm, Others in the Global Chopped Strands for Thermoplastics Market:

In the Global Chopped Strands for Thermoplastics Market, the diameter of the strands plays a crucial role in determining their performance characteristics and suitability for various applications. The most common diameters are 10μm, 11μm, and 13μm, with each offering distinct advantages. Strands with a diameter of 10μm are typically used in applications where a high surface area is required, as their smaller size allows for more strands to be packed into a given volume. This can enhance the mechanical properties of the thermoplastic, making it more suitable for applications that require high strength and durability. On the other hand, 11μm strands strike a balance between surface area and ease of processing. They are often used in applications where a moderate level of reinforcement is needed, and they offer good compatibility with a wide range of thermoplastic resins. The 13μm strands are generally used in applications where ease of processing is a priority, as their larger diameter makes them less prone to entanglement and easier to handle during manufacturing. These strands are often used in applications where the primary requirement is not maximum strength but rather ease of use and cost-effectiveness. In addition to these common diameters, there are also other sizes available, which are tailored to specific applications and requirements. These other sizes can offer unique benefits, such as improved thermal stability or enhanced resistance to chemical degradation, making them suitable for specialized applications in industries such as aerospace or medical devices. The choice of strand diameter is often dictated by the specific requirements of the application, as well as the properties of the thermoplastic resin being used. Manufacturers must carefully consider these factors when selecting the appropriate chopped strands for their products, as the wrong choice can lead to suboptimal performance or even failure of the final product. As the market for chopped strands continues to grow, there is an increasing focus on developing new and innovative products that can meet the evolving needs of various industries. This includes the development of strands with novel diameters or surface treatments that can enhance their performance in specific applications. Overall, the Global Chopped Strands for Thermoplastics Market is a complex and dynamic field, with a wide range of products available to meet the diverse needs of manufacturers and end-users.

Automotive, Construction, Electrical and Electronics, Others in the Global Chopped Strands for Thermoplastics Market:

The usage of Global Chopped Strands for Thermoplastics Market spans several key industries, each benefiting from the unique properties that these materials offer. In the automotive industry, chopped strands are used to reinforce thermoplastics in various components, such as bumpers, dashboards, and under-the-hood parts. The lightweight nature of these materials helps reduce the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. Additionally, the enhanced strength and durability provided by chopped strands ensure that automotive components can withstand the rigors of daily use and harsh environmental conditions. In the construction industry, chopped strands are used to reinforce thermoplastic materials in applications such as roofing, cladding, and piping. The added strength and durability provided by the strands make these materials ideal for use in demanding environments, where they must withstand exposure to the elements and heavy loads. The use of chopped strands in construction materials also contributes to the development of more sustainable building practices, as they can help reduce the overall weight and resource consumption of structures. In the electrical and electronics industry, chopped strands are used to reinforce thermoplastics in components such as connectors, housings, and circuit boards. The enhanced mechanical properties provided by the strands ensure that these components can withstand the stresses of assembly and operation, while also providing excellent electrical insulation and thermal stability. This makes them ideal for use in a wide range of electronic devices, from consumer electronics to industrial equipment. Beyond these key industries, chopped strands for thermoplastics are also used in a variety of other applications, such as sports equipment, consumer goods, and medical devices. In each of these areas, the unique properties of chopped strands help improve the performance and durability of products, while also enabling manufacturers to meet the specific requirements of their applications. As the demand for high-performance materials continues to grow, the usage of chopped strands in thermoplastics is expected to expand into new and emerging markets, driving further innovation and development in this dynamic field.

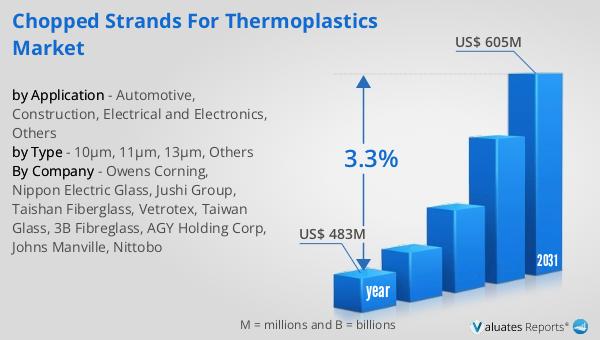

Global Chopped Strands for Thermoplastics Market Outlook:

The global market for Chopped Strands for Thermoplastics was valued at approximately $483 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $605 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.3% over the forecast period. This steady increase in market size reflects the rising demand for high-performance materials across various industries. The automotive, construction, and electronics sectors, in particular, are driving this demand as they seek materials that offer enhanced strength, durability, and lightweight properties. The market's growth is also supported by ongoing advancements in manufacturing technologies and the development of new and improved chopped strand products. These innovations are enabling manufacturers to produce materials that meet the increasingly stringent requirements of modern applications. Additionally, the push towards sustainability and environmentally friendly materials is further fueling the market's expansion, as chopped strands can contribute to the production of more eco-friendly products. Overall, the Global Chopped Strands for Thermoplastics Market is poised for continued growth, driven by the increasing demand for high-performance materials and the ongoing development of new and innovative products.

| Report Metric | Details |

| Report Name | Chopped Strands for Thermoplastics Market |

| Accounted market size in year | US$ 483 million |

| Forecasted market size in 2031 | US$ 605 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Owens Corning, Nippon Electric Glass, Jushi Group, Taishan Fiberglass, Vetrotex, Taiwan Glass, 3B Fibreglass, AGY Holding Corp, Johns Manville, Nittobo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |