What is Global Chopped Strands for Thermosets Market?

The Global Chopped Strands for Thermosets Market is a specialized segment within the broader composites industry, focusing on the production and application of chopped glass fibers used in thermosetting resins. These chopped strands are essentially short lengths of glass fibers that are mixed with thermosetting resins to create composite materials. The primary advantage of using chopped strands in thermosets is their ability to enhance the mechanical properties of the final product, such as strength, durability, and resistance to environmental factors. These materials are widely used in various industries, including automotive, construction, and electronics, due to their lightweight nature and high performance. The market is driven by the increasing demand for lightweight and high-strength materials, particularly in the automotive and aerospace sectors, where fuel efficiency and performance are critical. Additionally, the construction industry benefits from the use of these materials in applications requiring high durability and resistance to harsh environmental conditions. As industries continue to seek materials that offer a balance of performance and cost-effectiveness, the demand for chopped strands for thermosets is expected to grow. The market is characterized by a range of products tailored to specific applications, with ongoing research and development efforts aimed at enhancing the properties and applications of these composite materials.

in the Global Chopped Strands for Thermosets Market:

In the Global Chopped Strands for Thermosets Market, various types of chopped strands are utilized by different customers based on their specific needs and applications. These types are primarily distinguished by their fiber length, diameter, and the type of sizing applied to the fibers. The fiber length can vary, with shorter fibers typically used in applications requiring high flow and ease of processing, while longer fibers are preferred for applications demanding higher mechanical strength. The diameter of the fibers also plays a crucial role in determining the properties of the final composite material. Thinner fibers generally provide better surface finish and higher strength, whereas thicker fibers may be used in applications where cost is a more significant concern. The sizing applied to the fibers is another critical factor, as it affects the compatibility of the fibers with different types of thermosetting resins. Sizing is a chemical treatment applied to the surface of the fibers to enhance their bonding with the resin matrix. Different types of sizing are used depending on the resin system, such as epoxy, polyester, or vinyl ester, to ensure optimal performance of the composite material. Customers in the automotive industry, for example, may prioritize chopped strands with sizing compatible with epoxy resins, as these are commonly used in automotive components requiring high strength and durability. In contrast, the construction industry might focus on chopped strands with sizing suitable for polyester resins, which are often used in applications like roofing and cladding due to their cost-effectiveness and resistance to environmental factors. Additionally, the electronics industry may require chopped strands with specific electrical properties, necessitating the use of specialized sizing to achieve the desired performance. The choice of chopped strands is also influenced by the processing methods used in manufacturing the composite materials. For instance, injection molding and compression molding are common techniques in the production of thermoset composites, each requiring specific types of chopped strands to optimize the manufacturing process and the properties of the final product. Injection molding, which involves injecting the resin-fiber mixture into a mold, typically requires shorter fibers to ensure smooth flow and uniform distribution within the mold. Compression molding, on the other hand, involves placing the resin-fiber mixture into a mold and applying pressure to shape the material, often benefiting from longer fibers that provide enhanced strength and stiffness. The diversity of applications and processing methods in the Global Chopped Strands for Thermosets Market necessitates a wide range of products tailored to meet the specific requirements of different industries and customers. Manufacturers of chopped strands continuously innovate to develop new products with improved properties, such as higher strength-to-weight ratios, better thermal stability, and enhanced resistance to environmental factors. These advancements are driven by the evolving needs of industries seeking materials that offer a combination of performance, cost-effectiveness, and sustainability. As a result, the market for chopped strands for thermosets is characterized by a dynamic landscape of products and technologies, with ongoing research and development efforts aimed at expanding the applications and capabilities of these versatile composite materials.

Automotive, Construction, Others in the Global Chopped Strands for Thermosets Market:

The usage of Global Chopped Strands for Thermosets Market in various sectors such as automotive, construction, and others highlights the versatility and adaptability of these materials. In the automotive industry, chopped strands for thermosets are extensively used to manufacture components that require a high strength-to-weight ratio. These materials contribute to the production of lightweight vehicles, which are essential for improving fuel efficiency and reducing emissions. Components such as engine covers, interior panels, and underbody shields benefit from the enhanced mechanical properties provided by chopped strands, including increased impact resistance and thermal stability. The ability to mold these materials into complex shapes also allows for greater design flexibility, enabling manufacturers to create innovative and aerodynamic vehicle designs. In the construction industry, chopped strands for thermosets are utilized in applications that demand durability and resistance to environmental factors. These materials are commonly used in the production of roofing materials, cladding, and insulation products, where their resistance to moisture, UV radiation, and temperature fluctuations is crucial. The lightweight nature of these composites also facilitates easier handling and installation, reducing labor costs and construction time. Additionally, the use of chopped strands in construction materials can enhance the structural integrity of buildings, providing increased safety and longevity. Beyond automotive and construction, chopped strands for thermosets find applications in a variety of other industries. In the electronics sector, these materials are used to produce components that require electrical insulation and thermal management properties. The ability to tailor the properties of chopped strands through the selection of fiber length, diameter, and sizing allows manufacturers to meet the specific requirements of electronic applications, such as circuit boards and enclosures. The marine industry also benefits from the use of chopped strands for thermosets, particularly in the production of boat hulls and decks, where resistance to water and corrosion is essential. The versatility of these materials extends to the sports and leisure industry, where they are used to manufacture equipment such as helmets, bicycles, and sporting goods that require a combination of strength, lightweight, and durability. The adaptability of chopped strands for thermosets to various applications underscores their importance in modern manufacturing and their potential for future growth as industries continue to seek materials that offer a balance of performance, cost-effectiveness, and sustainability.

Global Chopped Strands for Thermosets Market Outlook:

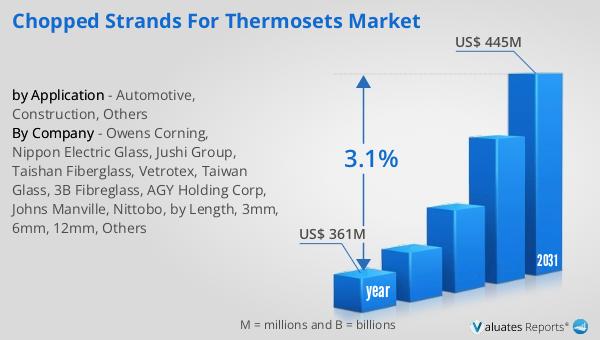

The global market for Chopped Strands for Thermosets was valued at $361 million in 2024, with projections indicating it will grow to a revised size of $445 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.1% over the forecast period. This market outlook reflects the increasing demand for high-performance composite materials across various industries. The automotive sector, in particular, is a significant driver of this growth, as manufacturers seek lightweight materials to enhance fuel efficiency and reduce emissions. Similarly, the construction industry is adopting these materials for their durability and resistance to environmental factors, contributing to the market's expansion. The electronics and marine industries also play a role in this growth, utilizing chopped strands for thermosets in applications that require specific mechanical and thermal properties. The steady growth of this market is indicative of the broader trend towards the adoption of advanced composite materials in manufacturing, driven by the need for materials that offer a combination of strength, lightweight, and cost-effectiveness. As industries continue to innovate and develop new applications for these materials, the demand for chopped strands for thermosets is expected to remain robust, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Chopped Strands for Thermosets Market |

| Accounted market size in year | US$ 361 million |

| Forecasted market size in 2031 | US$ 445 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Owens Corning, Nippon Electric Glass, Jushi Group, Taishan Fiberglass, Vetrotex, Taiwan Glass, 3B Fibreglass, AGY Holding Corp, Johns Manville, Nittobo, by Length, 3mm, 6mm, 12mm, Others |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |