What is Global Chopped Fiberglass for Thermosets Market?

The Global Chopped Fiberglass for Thermosets Market is a specialized segment within the broader fiberglass industry, focusing on the production and application of chopped fiberglass strands used in thermosetting resins. These materials are integral to enhancing the mechanical properties of thermosets, which are polymers that irreversibly cure to form a solid material. Chopped fiberglass is created by cutting continuous strands of fiberglass into shorter lengths, typically ranging from a few millimeters to several centimeters. This form of fiberglass is particularly valued for its ability to reinforce thermosetting plastics, providing increased strength, durability, and resistance to heat and chemicals. The market for chopped fiberglass in thermosets is driven by its widespread application across various industries, including automotive, construction, and electronics, where the demand for lightweight, high-strength materials is continually growing. As industries seek to improve the performance and sustainability of their products, the role of chopped fiberglass in thermosets becomes increasingly significant. This market is characterized by ongoing innovation and development, as manufacturers strive to enhance the properties of fiberglass and expand its applications. The global reach of this market underscores its importance in modern manufacturing and material science.

in the Global Chopped Fiberglass for Thermosets Market:

In the Global Chopped Fiberglass for Thermosets Market, various types of chopped fiberglass are utilized by customers based on specific requirements and applications. These types are primarily distinguished by the length of the fibers, the type of glass used, and the sizing or coating applied to the fibers. The length of the chopped fibers can vary significantly, with shorter fibers typically used in applications requiring high flow and ease of processing, while longer fibers are preferred for applications demanding higher mechanical strength and impact resistance. The type of glass used in the fibers, such as E-glass or S-glass, also plays a crucial role in determining the properties of the final composite material. E-glass, known for its electrical insulation properties and cost-effectiveness, is widely used in general applications, whereas S-glass offers superior strength and is used in high-performance applications. Additionally, the sizing or coating applied to the fibers is critical in ensuring compatibility with the thermosetting resin and enhancing the adhesion between the fibers and the matrix. This coating can be tailored to optimize the performance of the composite in specific environments, such as high humidity or chemical exposure. Customers in this market range from automotive manufacturers seeking lightweight materials to reduce vehicle weight and improve fuel efficiency, to construction companies looking for durable materials that can withstand harsh environmental conditions. The electronics industry also utilizes chopped fiberglass in thermosets for components that require high thermal stability and electrical insulation. Each customer segment has unique requirements that drive the selection of specific types of chopped fiberglass, making customization and flexibility key aspects of this market. As the demand for advanced materials continues to grow, the variety and specialization of chopped fiberglass products are expected to expand, offering customers an increasingly diverse range of options to meet their specific needs.

Automotive, Construction, Others in the Global Chopped Fiberglass for Thermosets Market:

The usage of Global Chopped Fiberglass for Thermosets Market in the automotive industry is primarily driven by the need for lightweight, high-strength materials that can enhance vehicle performance and fuel efficiency. Chopped fiberglass is used in various automotive components, including body panels, interior parts, and under-the-hood applications, where its ability to reduce weight without compromising strength is highly valued. The material's resistance to heat and chemicals also makes it suitable for use in engine components and other high-temperature environments. In the construction industry, chopped fiberglass is used to reinforce concrete, plastics, and other building materials, providing enhanced durability and resistance to environmental factors such as moisture, UV radiation, and temperature fluctuations. This makes it an ideal choice for applications in infrastructure projects, residential and commercial buildings, and other construction projects where long-term performance and reliability are critical. Beyond automotive and construction, chopped fiberglass for thermosets finds applications in a variety of other industries, including electronics, aerospace, and consumer goods. In the electronics industry, it is used in the production of printed circuit boards and other components that require high thermal stability and electrical insulation. In aerospace, the material's lightweight and high-strength properties are leveraged in the production of aircraft components, contributing to improved fuel efficiency and performance. In consumer goods, chopped fiberglass is used in the production of sports equipment, appliances, and other products where durability and performance are important. The versatility and adaptability of chopped fiberglass make it a valuable material across a wide range of applications, driving its continued growth and development in the global market.

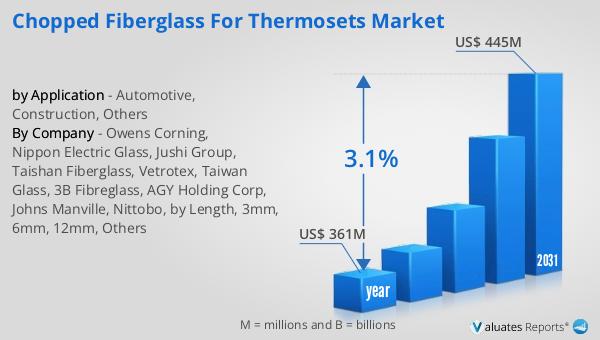

Global Chopped Fiberglass for Thermosets Market Outlook:

The global market for Chopped Fiberglass for Thermosets was valued at $361 million in 2024, with projections indicating an increase to $445 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.1% over the forecast period. This upward trend reflects the increasing demand for high-performance materials across various industries, driven by the need for lightweight, durable, and cost-effective solutions. The automotive industry, in particular, is a significant driver of this market, as manufacturers seek to reduce vehicle weight and improve fuel efficiency through the use of advanced composite materials. Similarly, the construction industry is adopting chopped fiberglass for its ability to enhance the strength and durability of building materials, contributing to the market's growth. The electronics and aerospace industries also play a role in this expansion, as they continue to seek materials that offer superior thermal stability and mechanical properties. As the market evolves, manufacturers are focusing on innovation and development to meet the diverse needs of their customers, offering a wide range of products tailored to specific applications. This focus on customization and flexibility is expected to further drive the growth of the Global Chopped Fiberglass for Thermosets Market, as industries continue to prioritize performance and sustainability in their material choices.

| Report Metric | Details |

| Report Name | Chopped Fiberglass for Thermosets Market |

| Accounted market size in year | US$ 361 million |

| Forecasted market size in 2031 | US$ 445 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Owens Corning, Nippon Electric Glass, Jushi Group, Taishan Fiberglass, Vetrotex, Taiwan Glass, 3B Fibreglass, AGY Holding Corp, Johns Manville, Nittobo, by Length, 3mm, 6mm, 12mm, Others |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |