What is Global Stamping Leadframes Market?

The Global Stamping Leadframes Market is a crucial segment within the semiconductor industry, primarily focusing on the production and supply of leadframes used in various electronic components. Leadframes are essential components in semiconductor packaging, serving as the metal structures that support and connect the semiconductor die to the external circuitry. These structures are typically made from materials like copper, iron, or nickel alloys, which are stamped into specific shapes to fit different types of semiconductor packages. The demand for stamping leadframes is driven by the increasing production of electronic devices, including smartphones, computers, and automotive electronics, which require efficient and reliable semiconductor components. As technology advances, the need for miniaturized and high-performance electronic devices continues to grow, further propelling the demand for sophisticated leadframe designs. The market is characterized by continuous innovation and development to meet the evolving requirements of the electronics industry, such as improved thermal performance and electrical conductivity. Additionally, the global push towards more environmentally friendly manufacturing processes has led to the adoption of lead-free and halogen-free materials in leadframe production. This market is expected to expand as the electronics industry continues to evolve and diversify, with Asia-Pacific being a significant contributor due to its robust electronics manufacturing sector.

SOP, SIP, DIP, QFN, QFP, SOIC, Others in the Global Stamping Leadframes Market:

In the Global Stamping Leadframes Market, several types of packages are prevalent, each serving specific functions and applications. SOP, or Small Outline Package, is a type of surface-mounted integrated circuit package that is widely used due to its compact size and efficient heat dissipation properties. It is commonly found in applications where space is a constraint, such as in consumer electronics and automotive systems. SIP, or Single In-line Package, is another type of package that features a single row of connecting pins. This package is often used in applications where simplicity and cost-effectiveness are prioritized, such as in power supplies and audio equipment. DIP, or Dual In-line Package, is a traditional package type that features two parallel rows of connecting pins. It is commonly used in through-hole mounting applications and is favored for its ease of handling and soldering. QFN, or Quad Flat No-leads, is a surface-mounted package that offers excellent thermal and electrical performance. It is often used in high-frequency applications and is favored for its small footprint and low profile. QFP, or Quad Flat Package, is another surface-mounted package that features leads extending from all four sides. It is commonly used in applications requiring high pin counts, such as microcontrollers and digital signal processors. SOIC, or Small Outline Integrated Circuit, is a surface-mounted package that is similar to SOP but with a smaller footprint. It is often used in applications where board space is limited, such as in portable devices and telecommunications equipment. Other package types in the Global Stamping Leadframes Market include LGA (Land Grid Array), BGA (Ball Grid Array), and CSP (Chip Scale Package), each offering unique advantages in terms of size, performance, and cost. These diverse package types cater to the varying needs of the electronics industry, ensuring that manufacturers can select the most suitable option for their specific applications.

Integrated Circuit, Discrete Device, Others in the Global Stamping Leadframes Market:

The Global Stamping Leadframes Market plays a vital role in the production of Integrated Circuits (ICs), Discrete Devices, and other electronic components. In the realm of Integrated Circuits, leadframes serve as the backbone that supports the semiconductor die and facilitates electrical connections to the external circuitry. The demand for ICs is driven by the proliferation of electronic devices, including smartphones, computers, and automotive electronics, which require efficient and reliable semiconductor components. Leadframes are essential in ensuring the performance and reliability of these ICs, as they provide the necessary mechanical support and electrical pathways. In the case of Discrete Devices, which include components like diodes, transistors, and rectifiers, leadframes are equally important. These devices are used in a wide range of applications, from power management systems to signal processing circuits. The use of leadframes in discrete devices ensures that these components can withstand the thermal and electrical stresses encountered during operation. Additionally, leadframes are used in other electronic components, such as sensors and optoelectronic devices, where they provide the necessary support and connectivity. The versatility and adaptability of leadframes make them indispensable in the electronics industry, as they cater to the diverse needs of various applications. As technology continues to advance, the demand for high-performance and miniaturized electronic components is expected to grow, further driving the need for innovative leadframe solutions.

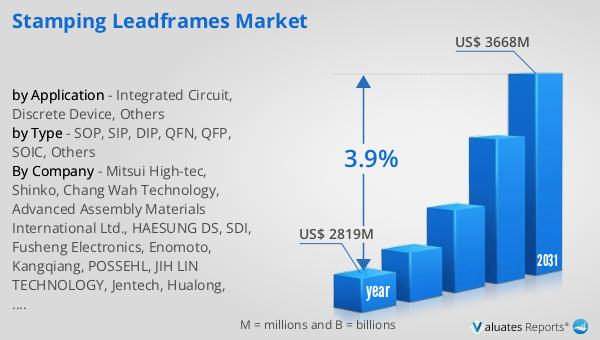

Global Stamping Leadframes Market Outlook:

In 2024, the global market for Stamping Leadframes was valued at approximately 2,819 million USD. This market is anticipated to experience growth, reaching an estimated size of 3,668 million USD by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. The steady increase in market size reflects the rising demand for electronic devices and the corresponding need for efficient semiconductor components. As the electronics industry continues to evolve, the demand for advanced leadframe designs that offer improved thermal performance and electrical conductivity is expected to rise. This growth is further supported by the increasing adoption of environmentally friendly manufacturing processes, such as lead-free and halogen-free materials, which align with global sustainability goals. The Asia-Pacific region is expected to play a significant role in this market expansion, given its robust electronics manufacturing sector and the presence of key industry players. Overall, the Global Stamping Leadframes Market is poised for steady growth, driven by technological advancements and the increasing demand for high-performance electronic components.

| Report Metric | Details |

| Report Name | Stamping Leadframes Market |

| Accounted market size in year | US$ 2819 million |

| Forecasted market size in 2031 | US$ 3668 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsui High-tec, Shinko, Chang Wah Technology, Advanced Assembly Materials International Ltd., HAESUNG DS, SDI, Fusheng Electronics, Enomoto, Kangqiang, POSSEHL, JIH LIN TECHNOLOGY, Jentech, Hualong, Dynacraft Industries, QPL Limited, WuXi Micro Just-Tech, HUAYANG ELECTRONIC, DNP, Xiamen Jsun Precision Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |