What is Global Strain Gauge Pressure Sensor Market?

The Global Strain Gauge Pressure Sensor Market is a specialized segment within the broader sensor industry, focusing on devices that measure pressure using strain gauges. These sensors are essential in various applications, from industrial machinery to consumer electronics, due to their ability to provide accurate and reliable pressure measurements. Strain gauge pressure sensors work by detecting the deformation of a material when pressure is applied, which is then converted into an electrical signal. This market is driven by the increasing demand for precise pressure measurement in industries such as automotive, aerospace, healthcare, and manufacturing. The sensors are valued for their high sensitivity, durability, and ability to operate in harsh environments. As technology advances, the market is witnessing innovations that enhance sensor performance, such as improved materials and miniaturization. The global market is characterized by a mix of established players and new entrants, all striving to offer advanced solutions to meet the evolving needs of various sectors. With the growing emphasis on automation and the Internet of Things (IoT), the demand for strain gauge pressure sensors is expected to continue rising, making it a dynamic and competitive market.

Analog Output, Digital Output in the Global Strain Gauge Pressure Sensor Market:

In the Global Strain Gauge Pressure Sensor Market, the output of these sensors can be categorized into two main types: analog and digital. Analog output sensors provide a continuous signal that is proportional to the pressure applied. This type of output is often preferred in applications where real-time monitoring is crucial, as it allows for a smooth and immediate response to changes in pressure. Analog sensors are typically simpler in design and can be more cost-effective, making them suitable for a wide range of applications, from industrial machinery to automotive systems. They are particularly useful in environments where the sensor needs to operate without complex digital processing, providing a straightforward and reliable measurement solution. On the other hand, digital output sensors convert the pressure measurement into a digital signal, which can be easily integrated with modern digital systems. This type of output is advantageous in applications that require precise data processing and integration with digital control systems. Digital sensors offer higher accuracy and can include features such as self-calibration and diagnostics, making them ideal for advanced applications in sectors like aerospace and healthcare. The choice between analog and digital output depends on the specific requirements of the application, including factors such as accuracy, cost, and integration capabilities. As technology continues to evolve, the distinction between analog and digital outputs is becoming less pronounced, with many modern sensors offering hybrid solutions that combine the benefits of both. This trend is driven by the increasing demand for versatile and adaptable sensors that can meet the diverse needs of various industries. In summary, the Global Strain Gauge Pressure Sensor Market offers a range of output options to suit different applications, with both analog and digital sensors playing a crucial role in meeting the growing demand for accurate and reliable pressure measurement.

Gas And Oil Fields, Dangerous Gases, Chemical, Other in the Global Strain Gauge Pressure Sensor Market:

The Global Strain Gauge Pressure Sensor Market finds extensive usage in various sectors, including gas and oil fields, dangerous gases, chemical industries, and other applications. In gas and oil fields, these sensors are critical for monitoring pressure levels in pipelines and storage tanks, ensuring the safe and efficient operation of extraction and transportation processes. The harsh and demanding environments of these fields require sensors that are robust and capable of withstanding extreme conditions, making strain gauge pressure sensors an ideal choice. In applications involving dangerous gases, these sensors play a vital role in detecting pressure changes that could indicate leaks or other hazardous situations. The ability to provide accurate and timely measurements is crucial for maintaining safety and preventing accidents. In the chemical industry, strain gauge pressure sensors are used to monitor pressure in reactors and other equipment, ensuring that processes are carried out under optimal conditions. The sensors' high sensitivity and reliability make them indispensable tools for maintaining product quality and safety. Beyond these specific industries, strain gauge pressure sensors are also used in a variety of other applications, from HVAC systems to medical devices, where precise pressure measurement is essential. The versatility and adaptability of these sensors make them valuable assets in any application where pressure monitoring is required. As industries continue to evolve and demand more sophisticated solutions, the role of strain gauge pressure sensors is expected to grow, driven by the need for accurate, reliable, and efficient pressure measurement across a wide range of applications.

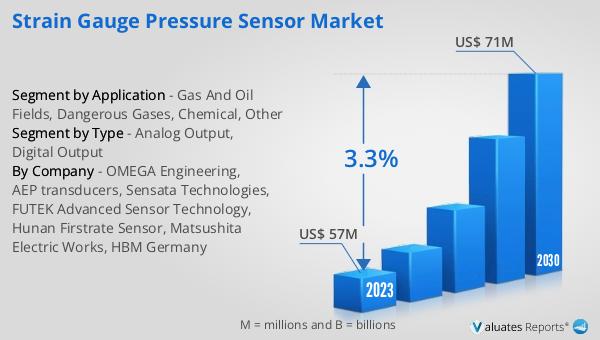

Global Strain Gauge Pressure Sensor Market Outlook:

The outlook for the Global Strain Gauge Pressure Sensor Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $60 million, reflecting its significance in various industrial applications. By 2031, it is anticipated that the market will expand to a revised size of $75 million, driven by a compound annual growth rate (CAGR) of 3.3% during the forecast period. This growth is indicative of the increasing demand for precise pressure measurement solutions across different sectors, including automotive, aerospace, healthcare, and manufacturing. The market's expansion is supported by technological advancements that enhance sensor performance, such as improved materials and miniaturization, which enable the development of more efficient and reliable sensors. Additionally, the growing emphasis on automation and the Internet of Things (IoT) is contributing to the rising demand for strain gauge pressure sensors, as these technologies require accurate and reliable pressure measurement to function effectively. The market is characterized by a mix of established players and new entrants, all striving to offer advanced solutions to meet the evolving needs of various industries. As the market continues to grow, it presents opportunities for innovation and development, making it a dynamic and competitive landscape.

| Report Metric | Details |

| Report Name | Strain Gauge Pressure Sensor Market |

| Accounted market size in year | US$ 60 million |

| Forecasted market size in 2031 | US$ 75 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | OMEGA Engineering, AEP transducers, Sensata Technologies, FUTEK Advanced Sensor Technology, Hunan Firstrate Sensor, Matsushita Electric Works, HBM Germany |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |