What is Global Copper CMP Slurries Market?

The Global Copper CMP Slurries Market is a specialized segment within the semiconductor industry, focusing on the chemical mechanical planarization (CMP) process. CMP is a critical step in semiconductor manufacturing, used to smooth and flatten the surfaces of wafers. Copper CMP slurries are specifically formulated mixtures used in this process to polish copper layers on semiconductor wafers. These slurries consist of abrasive particles suspended in a chemical solution, which helps in the controlled removal of excess material from the wafer surface. The demand for copper CMP slurries is driven by the increasing complexity and miniaturization of semiconductor devices, which require precise and efficient planarization techniques. As the semiconductor industry continues to evolve, the need for advanced CMP slurries that can deliver high performance and reliability becomes more pronounced. The market for these slurries is influenced by technological advancements, the growth of the semiconductor industry, and the increasing adoption of copper interconnects in integrated circuits. Overall, the Global Copper CMP Slurries Market plays a vital role in enabling the production of high-performance semiconductor devices, supporting the advancement of technology across various sectors.

Colloidal Silica Based Slurry, Alumina Based Slurry in the Global Copper CMP Slurries Market:

Colloidal silica-based slurry and alumina-based slurry are two prominent types of slurries used in the Global Copper CMP Slurries Market. Colloidal silica-based slurries are composed of silica particles suspended in a liquid medium. These slurries are known for their excellent polishing performance and ability to achieve a high degree of planarity on copper surfaces. The silica particles in the slurry act as abrasives, gently removing excess material from the wafer surface while maintaining the integrity of the underlying layers. Colloidal silica-based slurries are favored for their ability to produce smooth and defect-free surfaces, making them ideal for applications where precision and surface quality are paramount. On the other hand, alumina-based slurries utilize alumina particles as the abrasive component. Alumina is a harder material compared to silica, which makes alumina-based slurries more aggressive in material removal. This characteristic is beneficial in applications where faster removal rates are required. However, the increased abrasiveness of alumina-based slurries can also lead to higher defect rates if not carefully controlled. Therefore, the choice between colloidal silica-based and alumina-based slurries depends on the specific requirements of the CMP process, including the desired removal rate, surface quality, and defect tolerance. Both types of slurries are essential in the Global Copper CMP Slurries Market, catering to different needs and applications within the semiconductor manufacturing process. As the demand for advanced semiconductor devices continues to grow, the development and optimization of these slurries remain a key focus for manufacturers, ensuring that they can meet the evolving needs of the industry.

Logic Chips, Memory Chips, Advanced Packaging in the Global Copper CMP Slurries Market:

The Global Copper CMP Slurries Market finds significant usage in the production of logic chips, memory chips, and advanced packaging solutions. Logic chips, which serve as the brains of electronic devices, require precise and efficient planarization to ensure optimal performance. Copper CMP slurries play a crucial role in this process by enabling the smooth and uniform removal of excess copper material from the wafer surface. This ensures that the intricate patterns and structures on the logic chips are accurately formed, leading to improved performance and reliability. Similarly, in the production of memory chips, copper CMP slurries are used to achieve the necessary planarity and surface quality. Memory chips, which store and retrieve data in electronic devices, rely on precise manufacturing processes to function effectively. The use of copper CMP slurries helps in achieving the required surface smoothness and uniformity, which are critical for the performance and longevity of memory chips. In advanced packaging, copper CMP slurries are used to create the interconnects and structures that connect different components within a semiconductor device. Advanced packaging techniques, such as 3D stacking and system-in-package (SiP), require precise planarization to ensure that the various layers and components are properly aligned and connected. Copper CMP slurries enable the creation of these complex structures by providing the necessary surface quality and planarity. Overall, the Global Copper CMP Slurries Market plays a vital role in the production of high-performance semiconductor devices, supporting the advancement of technology across various sectors.

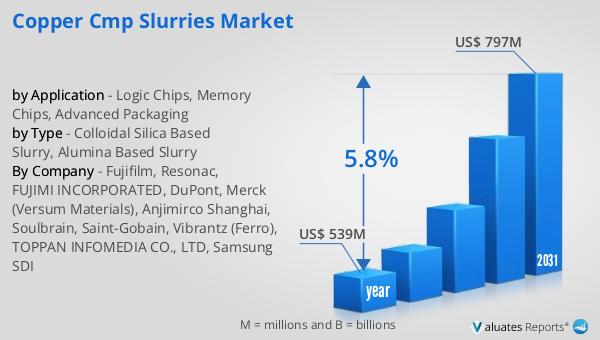

Global Copper CMP Slurries Market Outlook:

The worldwide market for Copper CMP Slurries was valued at $539 million in 2024 and is anticipated to expand to a revised size of $797 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. In 2023, the top five global players held approximately 77.4% of the market share in terms of revenue. The global semiconductor market was estimated at $526.8 billion in 2023 and is projected to reach $780.7 billion by 2030. Our research indicates that the global semiconductor manufacturing wafer fabrication market is expected to grow from $251.7 billion in 2023 to $506.5 billion by 2030, with a CAGR of 40.49% during the forecast period. This growth is driven by the increasing demand for advanced semiconductor devices and the continuous evolution of technology. The expansion of the Copper CMP Slurries Market is closely linked to the overall growth of the semiconductor industry, as these slurries are essential for the production of high-performance semiconductor devices. As the industry continues to advance, the demand for efficient and reliable CMP slurries is expected to rise, supporting the development of next-generation technologies.

| Report Metric | Details |

| Report Name | Copper CMP Slurries Market |

| Accounted market size in year | US$ 539 million |

| Forecasted market size in 2031 | US$ 797 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fujifilm, Resonac, FUJIMI INCORPORATED, DuPont, Merck (Versum Materials), Anjimirco Shanghai, Soulbrain, Saint-Gobain, Vibrantz (Ferro), TOPPAN INFOMEDIA CO., LTD, Samsung SDI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |