What is Global Halogen-free CCL Market?

The Global Halogen-free Copper Clad Laminate (CCL) Market is a specialized segment within the broader electronics materials industry. Halogen-free CCLs are used in the production of printed circuit boards (PCBs), which are essential components in a wide range of electronic devices. Unlike traditional CCLs, halogen-free variants do not contain halogens like bromine or chlorine, which are harmful to the environment and human health when burned. This makes them a more sustainable and eco-friendly option. The demand for halogen-free CCLs is driven by increasing environmental regulations and the growing awareness of the need for sustainable manufacturing practices. These materials are particularly important in industries where safety and environmental impact are critical considerations, such as consumer electronics, automotive, and telecommunications. As technology advances and the demand for electronic devices continues to grow, the market for halogen-free CCLs is expected to expand, offering opportunities for innovation and development in materials science and engineering.

Thermal Conduction, High Frequency, Other in the Global Halogen-free CCL Market:

Thermal conduction, high frequency, and other properties are critical factors in the performance and application of Global Halogen-free CCLs. Thermal conduction refers to the ability of a material to conduct heat. In the context of halogen-free CCLs, efficient thermal conduction is essential to manage the heat generated by electronic components during operation. This is particularly important in high-performance applications where excessive heat can lead to device failure or reduced efficiency. Halogen-free CCLs with good thermal conduction properties help in dissipating heat effectively, ensuring the reliability and longevity of electronic devices. High-frequency applications require materials that can handle rapid changes in electrical signals without significant loss or distortion. Halogen-free CCLs designed for high-frequency use are engineered to minimize signal loss and maintain signal integrity, which is crucial for applications in telecommunications, radar systems, and high-speed computing. These materials must exhibit low dielectric loss and stable dielectric constants to perform effectively at high frequencies. Other properties of halogen-free CCLs include mechanical strength, moisture resistance, and chemical stability. These characteristics ensure that the CCLs can withstand the physical and environmental stresses encountered during manufacturing and operation. Mechanical strength is important for the structural integrity of the PCBs, while moisture resistance prevents degradation in humid environments. Chemical stability ensures that the materials do not react adversely with other components or substances they may come into contact with. The development of halogen-free CCLs with these enhanced properties involves advanced material science and engineering techniques. Researchers and manufacturers work to optimize the composition and structure of these materials to meet the specific demands of different applications. This includes the use of novel resins, fillers, and reinforcement materials that provide the desired balance of properties. The push for halogen-free materials is also driven by regulatory requirements and industry standards aimed at reducing the environmental impact of electronic waste. As a result, manufacturers are investing in research and development to create halogen-free CCLs that not only meet performance requirements but also comply with environmental regulations. The market for halogen-free CCLs is characterized by continuous innovation as companies strive to develop materials that offer superior performance while being environmentally friendly. This includes the exploration of new material combinations and manufacturing processes that enhance the thermal, electrical, and mechanical properties of the CCLs. As the demand for electronic devices continues to grow, the need for high-performance, sustainable materials like halogen-free CCLs will become increasingly important. This presents opportunities for companies to differentiate themselves through innovation and to contribute to the development of more sustainable electronics.

Consumer Electronics, Mobile Phone, Notebook, Other in the Global Halogen-free CCL Market:

The usage of Global Halogen-free CCLs in consumer electronics, mobile phones, notebooks, and other areas highlights their versatility and importance in modern technology. In consumer electronics, halogen-free CCLs are used in a wide range of devices, from televisions and audio equipment to home appliances and gaming consoles. These materials provide the necessary electrical and thermal performance while ensuring compliance with environmental regulations. The shift towards more sustainable products has led manufacturers to adopt halogen-free CCLs as a standard in their production processes. In mobile phones, halogen-free CCLs are critical components that contribute to the device's overall performance and reliability. Mobile phones require materials that can handle high-frequency signals and manage heat effectively, as they are used for various applications such as communication, internet browsing, and multimedia. Halogen-free CCLs provide the necessary properties to support these functions while being environmentally friendly. The compact size and high functionality of modern mobile phones demand materials that offer excellent performance without compromising on safety or sustainability. Notebooks and laptops also benefit from the use of halogen-free CCLs. These devices require materials that can support high-speed processing and efficient heat dissipation, as they are often used for demanding applications such as gaming, video editing, and software development. Halogen-free CCLs provide the necessary thermal and electrical properties to ensure the smooth operation of notebooks while adhering to environmental standards. The trend towards thinner and lighter devices further emphasizes the need for advanced materials that can deliver high performance in a compact form factor. In addition to consumer electronics, mobile phones, and notebooks, halogen-free CCLs are used in various other applications, including automotive electronics, telecommunications, and industrial equipment. In the automotive industry, these materials are used in electronic control units, infotainment systems, and advanced driver-assistance systems (ADAS). The need for reliable and environmentally friendly materials is critical in automotive applications, where safety and performance are paramount. In telecommunications, halogen-free CCLs are used in network infrastructure and communication devices, where they support high-frequency signals and ensure reliable connectivity. The demand for faster and more efficient communication networks drives the need for materials that can handle high data rates and maintain signal integrity. Industrial equipment also benefits from the use of halogen-free CCLs, as these materials provide the necessary durability and performance in harsh environments. The versatility of halogen-free CCLs makes them suitable for a wide range of applications, and their adoption is expected to grow as industries continue to prioritize sustainability and performance.

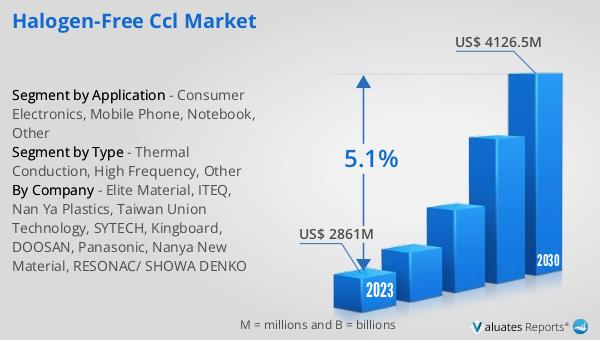

Global Halogen-free CCL Market Outlook:

The global market for Halogen-free CCL was valued at $3,201 million in 2024, and it is anticipated to expand to a revised size of $4,515 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth trajectory underscores the increasing demand for environmentally friendly materials in the electronics industry. As regulatory pressures and consumer awareness about the environmental impact of electronic waste intensify, manufacturers are compelled to adopt sustainable practices, including the use of halogen-free materials. The projected growth of the halogen-free CCL market is indicative of a broader trend towards sustainability in manufacturing processes. Companies are investing in research and development to enhance the performance and cost-effectiveness of halogen-free CCLs, making them a viable alternative to traditional materials. This shift is not only driven by regulatory compliance but also by the competitive advantage that sustainable products offer in the marketplace. As industries such as consumer electronics, automotive, and telecommunications continue to evolve, the demand for high-performance, eco-friendly materials like halogen-free CCLs is expected to rise, contributing to the market's growth. The expansion of the halogen-free CCL market reflects a growing recognition of the importance of sustainability in the electronics industry and the potential for innovation in materials science to drive positive change.

| Report Metric | Details |

| Report Name | Halogen-free CCL Market |

| Accounted market size in year | US$ 3201 million |

| Forecasted market size in 2031 | US$ 4515 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Elite Material, ITEQ, Nan Ya Plastics, Taiwan Union Technology, SYTECH, Kingboard, DOOSAN, Panasonic, Nanya New Material, RESONAC/ SHOWA DENKO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |