What is Global Industrial Vibration Sensor Market?

The Global Industrial Vibration Sensor Market is a critical component of modern industrial operations, playing a vital role in monitoring and maintaining the health of machinery and equipment. These sensors are designed to detect and measure vibrations in industrial machines, which can indicate potential issues such as imbalance, misalignment, or wear and tear. By providing real-time data on machine conditions, vibration sensors help in predictive maintenance, reducing downtime and preventing costly repairs. The market for these sensors is expanding due to the increasing demand for automation and the need for efficient monitoring systems in industries such as manufacturing, automotive, and energy. As industries strive for higher productivity and reduced operational costs, the adoption of vibration sensors is becoming more widespread. These sensors are available in various types, including velocity, displacement, and acceleration sensors, each serving specific applications and offering unique benefits. The growth of the Global Industrial Vibration Sensor Market is driven by technological advancements, the integration of IoT in industrial processes, and the rising awareness of the benefits of predictive maintenance. As industries continue to evolve, the demand for reliable and efficient vibration sensors is expected to grow, making them an indispensable tool in modern industrial operations.

Velocity Sensor, Displacement Sensor, Acceleration Sensor in the Global Industrial Vibration Sensor Market:

Velocity sensors, displacement sensors, and acceleration sensors are three primary types of vibration sensors used in the Global Industrial Vibration Sensor Market, each serving distinct purposes and applications. Velocity sensors are designed to measure the speed of vibration in a machine or structure. They are particularly useful in applications where the velocity of vibration is a critical parameter, such as in rotating machinery. These sensors help in identifying issues like imbalance or misalignment by providing data on the speed at which components are vibrating. Velocity sensors are often used in industries like automotive and manufacturing, where precise monitoring of machinery is essential for maintaining operational efficiency. Displacement sensors, on the other hand, measure the distance a vibrating object moves from its resting position. These sensors are crucial in applications where the amplitude of vibration is a key concern, such as in large structures or machinery with significant moving parts. Displacement sensors are commonly used in industries like construction and aerospace, where monitoring the displacement of components can prevent structural failures and ensure safety. Acceleration sensors measure the rate of change of velocity in a vibrating object. They are highly sensitive and can detect even the slightest changes in vibration, making them ideal for applications where early detection of potential issues is critical. Acceleration sensors are widely used in industries like electronics and telecommunications, where equipment is sensitive to vibrations and requires precise monitoring. Each type of sensor offers unique advantages and is chosen based on the specific requirements of the application. The integration of these sensors into industrial processes has been facilitated by advancements in technology, such as the development of wireless and smart sensors. These innovations have made it easier to collect and analyze vibration data, leading to more efficient and effective monitoring systems. As industries continue to adopt automation and digitalization, the demand for velocity, displacement, and acceleration sensors is expected to grow, driving the expansion of the Global Industrial Vibration Sensor Market. The versatility and reliability of these sensors make them indispensable tools in ensuring the smooth and efficient operation of industrial machinery and equipment.

HVAC Systems, Automotive, Food & Beverage, Water & Wastewater, Oil & Gas, Others in the Global Industrial Vibration Sensor Market:

The Global Industrial Vibration Sensor Market finds extensive usage across various sectors, including HVAC systems, automotive, food and beverage, water and wastewater, oil and gas, and others. In HVAC systems, vibration sensors are used to monitor the performance of compressors, fans, and motors. By detecting abnormal vibrations, these sensors help in identifying potential issues such as bearing failures or misalignments, allowing for timely maintenance and reducing the risk of system breakdowns. In the automotive industry, vibration sensors play a crucial role in ensuring the safety and reliability of vehicles. They are used to monitor the condition of engines, transmissions, and other critical components, providing data that can be used to predict failures and schedule maintenance. This not only enhances vehicle performance but also extends the lifespan of automotive components. In the food and beverage industry, vibration sensors are used to monitor the performance of processing equipment, such as mixers and conveyors. By detecting vibrations that indicate wear or misalignment, these sensors help in maintaining the quality and consistency of products while minimizing downtime. In the water and wastewater sector, vibration sensors are used to monitor pumps, motors, and other equipment. By providing real-time data on equipment conditions, these sensors help in preventing failures and ensuring the efficient operation of water treatment facilities. In the oil and gas industry, vibration sensors are used to monitor drilling equipment, pumps, and compressors. By detecting vibrations that indicate potential issues, these sensors help in preventing costly downtime and ensuring the safety of operations. The versatility of vibration sensors makes them suitable for a wide range of applications, including those in industries such as mining, aerospace, and manufacturing. As industries continue to prioritize efficiency and reliability, the demand for vibration sensors is expected to grow, driving the expansion of the Global Industrial Vibration Sensor Market. The ability of these sensors to provide real-time data and facilitate predictive maintenance makes them invaluable tools in modern industrial operations.

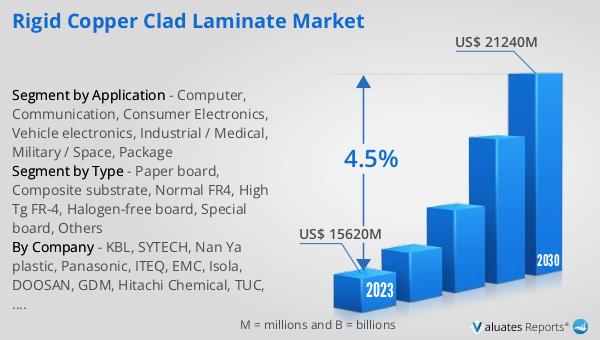

Global Industrial Vibration Sensor Market Outlook:

The global market for Industrial Vibration Sensors was valued at approximately $9.08 billion in 2024, and it is anticipated to grow significantly, reaching an estimated size of $14.48 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.0% over the forecast period. The increasing demand for these sensors is driven by the need for efficient monitoring systems in various industries, including manufacturing, automotive, and energy. As industries continue to adopt automation and digitalization, the integration of vibration sensors into industrial processes is becoming more prevalent. These sensors provide real-time data on machine conditions, enabling predictive maintenance and reducing downtime. The expansion of the Global Industrial Vibration Sensor Market is also supported by technological advancements, such as the development of wireless and smart sensors, which have made it easier to collect and analyze vibration data. As industries strive for higher productivity and reduced operational costs, the adoption of vibration sensors is expected to grow, making them an indispensable tool in modern industrial operations. The versatility and reliability of these sensors make them suitable for a wide range of applications, ensuring their continued demand and market growth.

| Report Metric | Details |

| Report Name | Industrial Vibration Sensor Market |

| Accounted market size in year | US$ 9080 million |

| Forecasted market size in 2031 | US$ 14480 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | General Electric Company, Schaeffler Group, Analog Devices, Omron, National Instruments, Wilcoxon Sensing Technologies, ETS Solutions, SKF Group, Preditec/IRM, ABB, Waites Wireless Sensor Technologies, Pruftechnik Dieter Busch, BeanAir Germany, I-Care Group, Evigia Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |