What is Global 3D Solder Paste Inspection (SPI) System Market?

The Global 3D Solder Paste Inspection (SPI) System Market is a specialized segment within the electronics manufacturing industry that focuses on the inspection of solder paste deposits on printed circuit boards (PCBs). Solder paste is a critical material used in the assembly of electronic components, and its precise application is essential for ensuring the reliability and performance of electronic devices. The 3D SPI systems utilize advanced imaging technology to create a three-dimensional representation of the solder paste deposits, allowing for accurate measurement of volume, height, and area. This level of precision is crucial for identifying defects such as insufficient or excessive solder paste, which can lead to poor electrical connections or short circuits. The market for these systems is driven by the increasing complexity of electronic devices, which require more sophisticated inspection techniques to ensure quality and reliability. As electronics continue to evolve, the demand for advanced inspection systems like 3D SPI is expected to grow, making it a vital component of modern electronics manufacturing.

Off-line SPI System, In-line SPI System in the Global 3D Solder Paste Inspection (SPI) System Market:

The Global 3D Solder Paste Inspection (SPI) System Market is divided into two main types: Off-line SPI Systems and In-line SPI Systems. Off-line SPI Systems are standalone units that are used separately from the production line. These systems are typically employed for batch inspection or quality control purposes, where samples of PCBs are taken from the production line and inspected in a separate area. Off-line systems are advantageous for their flexibility, as they can be used to inspect a wide range of PCB types and sizes without disrupting the production process. They are often used in smaller manufacturing operations or for prototyping and development purposes, where the focus is on ensuring the quality of a limited number of boards. In contrast, In-line SPI Systems are integrated directly into the production line, allowing for real-time inspection of every PCB as it is produced. These systems are essential for high-volume manufacturing environments, where speed and efficiency are critical. In-line systems provide immediate feedback on the quality of solder paste application, enabling manufacturers to quickly identify and correct any issues before they lead to defects in the final product. This real-time inspection capability is particularly important in industries such as automotive and consumer electronics, where the demand for high-quality, reliable products is paramount. In-line SPI Systems are designed to handle the high throughput of modern production lines, with advanced algorithms and high-speed cameras that can inspect thousands of boards per hour. They are also equipped with sophisticated software that can analyze the data collected during inspection and provide detailed reports on the quality of the solder paste application. This information is invaluable for process optimization, as it allows manufacturers to identify trends and make adjustments to their production processes to improve quality and efficiency. Both Off-line and In-line SPI Systems play a crucial role in the Global 3D Solder Paste Inspection (SPI) System Market, providing manufacturers with the tools they need to ensure the quality and reliability of their products. As the demand for more complex and miniaturized electronic devices continues to grow, the need for advanced inspection systems like these will only increase, driving further innovation and development in this important market segment.

Automotive Electronics, Consumer Electronics, Industrials, Others in the Global 3D Solder Paste Inspection (SPI) System Market:

The usage of Global 3D Solder Paste Inspection (SPI) Systems spans across various industries, each with its unique requirements and challenges. In the automotive electronics sector, the reliability and safety of electronic components are of utmost importance. Vehicles today are equipped with numerous electronic systems, from engine control units to advanced driver-assistance systems (ADAS). Any failure in these components can have serious consequences, making the inspection of solder paste deposits critical. 3D SPI systems ensure that the solder paste is applied correctly, reducing the risk of defects that could lead to component failure. In the consumer electronics industry, the demand for smaller, more powerful devices has led to increasingly complex PCB designs. Smartphones, tablets, and wearable devices all require precise solder paste application to function correctly. 3D SPI systems provide the accuracy needed to inspect these intricate designs, ensuring that each device meets the high standards expected by consumers. In industrial applications, electronic components are often subjected to harsh environments, where reliability is key. Equipment used in manufacturing, energy, and transportation sectors must operate flawlessly under extreme conditions. 3D SPI systems help ensure that the solder paste application is robust enough to withstand these challenges, providing manufacturers with the confidence that their products will perform as expected. Other industries, such as telecommunications and medical devices, also benefit from the use of 3D SPI systems. In telecommunications, the demand for high-speed, reliable networks requires electronic components that can handle large amounts of data without failure. 3D SPI systems help ensure that these components are manufactured to the highest standards, reducing the risk of network downtime. In the medical device industry, the stakes are even higher, as the failure of electronic components can have life-threatening consequences. 3D SPI systems provide the precision needed to inspect the solder paste application on these critical devices, ensuring that they meet the stringent quality requirements of the industry. Overall, the Global 3D Solder Paste Inspection (SPI) System Market plays a vital role in ensuring the quality and reliability of electronic components across a wide range of industries. As technology continues to advance, the demand for these systems is expected to grow, driving further innovation and development in this important market segment.

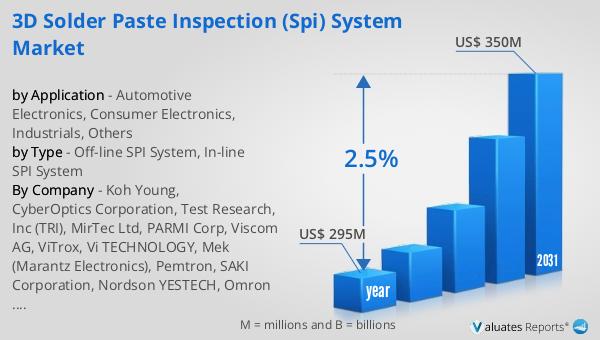

Global 3D Solder Paste Inspection (SPI) System Market Outlook:

The outlook for the Global 3D Solder Paste Inspection (SPI) System Market indicates a steady growth trajectory. In 2024, the market was valued at approximately US$ 295 million, and it is anticipated to expand to a revised size of US$ 350 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.5% over the forecast period. This steady increase reflects the growing demand for advanced inspection systems in the electronics manufacturing industry. Notably, companies such as Koh Young, Test Research, TRI, and SinicTek Vision Technology have established a significant presence in this market, collectively accounting for over 50% of the global market share. Their dominance underscores the importance of technological innovation and quality assurance in maintaining a competitive edge. As the electronics industry continues to evolve, the need for precise and reliable inspection systems like 3D SPI is expected to remain strong, driving further growth and development in this market. The ongoing advancements in electronic device complexity and miniaturization will likely continue to fuel the demand for these sophisticated inspection solutions, ensuring their critical role in the manufacturing process.

| Report Metric | Details |

| Report Name | 3D Solder Paste Inspection (SPI) System Market |

| Accounted market size in year | US$ 295 million |

| Forecasted market size in 2031 | US$ 350 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koh Young, CyberOptics Corporation, Test Research, Inc (TRI), MirTec Ltd, PARMI Corp, Viscom AG, ViTrox, Vi TECHNOLOGY, Mek (Marantz Electronics), Pemtron, SAKI Corporation, Nordson YESTECH, Omron Corporation, Goepel Electronic, Machine Vision Products (MVP), Caltex Scientific, ASC International, Sinic-Tek Vision Technology, Shenzhen JT Automation Equipment, Jet Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |