What is Global Industrial Motor Busbar Market?

The Global Industrial Motor Busbar Market is a crucial component of the electrical infrastructure that supports various industries worldwide. Busbars are metallic strips or bars used for conducting electricity within a switchboard, distribution board, substation, or other electrical apparatus. They are essential in distributing power efficiently and safely, minimizing energy loss, and reducing the risk of electrical faults. The market for industrial motor busbars is driven by the increasing demand for energy-efficient solutions and the need for reliable power distribution systems in industrial settings. As industries continue to expand and modernize, the demand for robust and efficient electrical systems grows, making busbars an integral part of this evolution. The market encompasses various types of busbars, including copper and aluminum, each offering distinct advantages in terms of conductivity, durability, and cost-effectiveness. With the global push towards sustainable energy solutions and the modernization of industrial infrastructure, the industrial motor busbar market is poised for significant growth, driven by technological advancements and the increasing adoption of smart grid technologies. This market plays a vital role in ensuring the seamless operation of industrial motors, generators, and other critical machinery, highlighting its importance in the global industrial landscape.

Copper Busbars, Aluminum Busbar in the Global Industrial Motor Busbar Market:

Copper busbars are a popular choice in the Global Industrial Motor Busbar Market due to their excellent electrical conductivity and thermal performance. Copper, being a highly conductive material, allows for efficient power transmission with minimal energy loss, making it ideal for high-current applications. Copper busbars are known for their durability and resistance to corrosion, which ensures a long service life even in harsh industrial environments. They are often used in applications where reliability and performance are paramount, such as in power distribution systems, switchgear, and motor control centers. The high conductivity of copper also allows for smaller busbar sizes, which can be advantageous in space-constrained installations. On the other hand, aluminum busbars offer a cost-effective alternative to copper, with the added benefit of being lightweight. Although aluminum has lower conductivity compared to copper, it is still widely used in the industrial motor busbar market due to its affordability and ease of installation. Aluminum busbars are often used in applications where weight is a critical factor, such as in aerospace and transportation industries. They are also favored in large-scale power distribution systems where cost savings are a priority. Despite the differences in conductivity, both copper and aluminum busbars play a vital role in the efficient distribution of electrical power in industrial settings. The choice between copper and aluminum often depends on the specific requirements of the application, including factors such as cost, weight, and environmental conditions. As the demand for energy-efficient and sustainable solutions continues to grow, the industrial motor busbar market is expected to see increased innovation and development in both copper and aluminum busbar technologies. This will likely lead to improved performance, reduced costs, and enhanced sustainability, further solidifying the importance of busbars in the global industrial landscape.

Motor, Generator in the Global Industrial Motor Busbar Market:

The Global Industrial Motor Busbar Market finds extensive usage in motors and generators, which are critical components in various industrial applications. In motors, busbars are used to distribute electrical power efficiently and reliably, ensuring optimal performance and longevity of the motor. They provide a low-resistance path for electrical current, minimizing energy loss and reducing the risk of overheating. This is particularly important in high-power motors used in industries such as manufacturing, mining, and transportation, where reliability and efficiency are crucial. Busbars also play a vital role in the design and operation of electric motors, allowing for compact and efficient configurations that can handle high current loads. In generators, busbars are used to collect and distribute the electrical power generated, ensuring a stable and reliable power supply. They are essential in maintaining the efficiency and performance of generators, which are often used as backup power sources in critical applications such as hospitals, data centers, and industrial plants. The use of busbars in generators helps to reduce energy loss and improve the overall efficiency of the power generation process. Additionally, busbars provide a flexible and scalable solution for power distribution, allowing for easy expansion and modification of electrical systems as needed. This is particularly important in industries that require adaptable and resilient power solutions to meet changing demands. The use of busbars in motors and generators highlights their importance in the global industrial landscape, providing reliable and efficient power distribution solutions that are essential for the smooth operation of industrial processes. As industries continue to evolve and modernize, the demand for advanced busbar technologies is expected to grow, driving innovation and development in the Global Industrial Motor Busbar Market.

Global Industrial Motor Busbar Market Outlook:

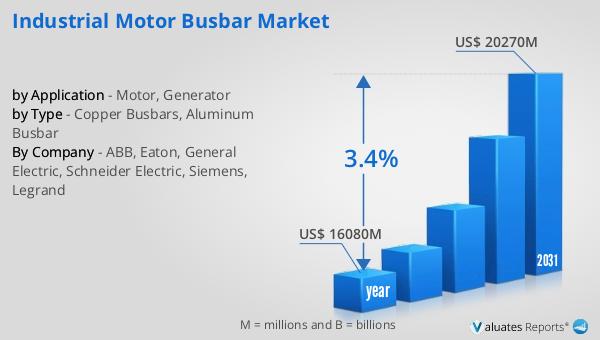

The global market for Industrial Motor Busbar was valued at approximately $16.08 billion in 2024, and it is anticipated to expand to around $20.27 billion by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable power distribution solutions in industrial settings. The market's expansion is driven by several factors, including the rising need for energy-efficient systems, the modernization of industrial infrastructure, and the growing adoption of smart grid technologies. As industries worldwide strive to enhance their operational efficiency and reduce energy consumption, the demand for advanced busbar solutions is expected to rise. The market's growth is also supported by technological advancements in busbar design and materials, which are leading to improved performance and cost-effectiveness. Additionally, the increasing focus on sustainability and the transition towards renewable energy sources are expected to drive further demand for industrial motor busbars, as they play a crucial role in the efficient distribution of electrical power. Overall, the Global Industrial Motor Busbar Market is poised for significant growth, driven by the ongoing evolution of industrial processes and the increasing emphasis on energy efficiency and sustainability.

| Report Metric | Details |

| Report Name | Industrial Motor Busbar Market |

| Accounted market size in year | US$ 16080 million |

| Forecasted market size in 2031 | US$ 20270 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Eaton, General Electric, Schneider Electric, Siemens, Legrand |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |