What is Global Food Grade Thermal Gel Market?

The Global Food Grade Thermal Gel Market is a specialized segment within the broader food industry, focusing on the production and distribution of thermal gels that are safe for consumption. These gels are used primarily for their thermal properties, which help in maintaining the temperature of food products during storage and transportation. This market is driven by the increasing demand for convenience foods and the need for effective temperature control solutions in the food supply chain. Food grade thermal gels are designed to be non-toxic and safe for use in direct contact with food, making them an essential component in the packaging of perishable goods. The market is characterized by a diverse range of products, each tailored to meet specific temperature requirements and food safety standards. As consumer awareness about food safety and quality continues to grow, the demand for food grade thermal gels is expected to rise, driving innovation and expansion within the market. Companies operating in this space are continually investing in research and development to enhance the performance and safety of their products, ensuring they meet the stringent regulations set by food safety authorities worldwide.

Purity ≥ 99%, Purity < 99% in the Global Food Grade Thermal Gel Market:

In the Global Food Grade Thermal Gel Market, purity levels play a crucial role in determining the quality and application of the products. Purity ≥ 99% refers to thermal gels that have a high level of purity, meaning they contain minimal impurities and are composed almost entirely of the active thermal gel ingredient. These high-purity gels are often preferred in applications where food safety and quality are of utmost importance, as they ensure that no harmful substances are introduced into the food products they come into contact with. The production of such high-purity gels requires advanced manufacturing processes and stringent quality control measures to ensure that the final product meets the necessary standards. On the other hand, Purity < 99% refers to thermal gels that contain a slightly higher level of impurities. While these gels may not be as pure as their ≥ 99% counterparts, they still meet the necessary safety and performance standards for use in the food industry. These gels are often used in applications where the highest level of purity is not required, allowing for a more cost-effective solution without compromising on safety. The choice between these two purity levels depends on the specific requirements of the application, with factors such as cost, performance, and regulatory compliance all playing a role in the decision-making process. Companies operating in the Global Food Grade Thermal Gel Market must carefully consider these factors when developing and marketing their products, ensuring they meet the diverse needs of their customers while adhering to the strict regulations governing food safety. The market for food grade thermal gels is highly competitive, with numerous players vying for a share of the growing demand. As a result, companies are continually seeking ways to differentiate their products, whether through the development of new formulations, improvements in manufacturing processes, or enhancements in product performance. This drive for innovation is essential in maintaining a competitive edge and ensuring long-term success in the market. Additionally, as consumer awareness of food safety and quality continues to rise, there is an increasing demand for transparency and traceability in the supply chain. Companies must be able to demonstrate the purity and safety of their products, providing customers with the assurance they need to make informed purchasing decisions. This emphasis on transparency is not only a regulatory requirement but also a key factor in building trust and loyalty among consumers. In conclusion, the Global Food Grade Thermal Gel Market is characterized by a focus on purity and safety, with companies striving to meet the diverse needs of their customers while adhering to strict regulatory standards. The choice between Purity ≥ 99% and Purity < 99% depends on the specific requirements of the application, with factors such as cost, performance, and regulatory compliance all playing a role in the decision-making process. As the market continues to grow, companies must remain committed to innovation and transparency, ensuring they meet the evolving needs of their customers and maintain a competitive edge in the industry.

Meat Products, Pasta Products, Bionic Vegetarian, Aquatic Products, Canned Products, Other in the Global Food Grade Thermal Gel Market:

The Global Food Grade Thermal Gel Market finds its application across a wide range of food products, each with its unique requirements and challenges. In the meat products sector, thermal gels are used to maintain the freshness and safety of products such as sausages, steaks, and poultry during transportation and storage. These gels help in regulating the temperature, ensuring that the meat remains at a safe temperature to prevent spoilage and bacterial growth. Similarly, in the pasta products segment, thermal gels are used to preserve the quality and texture of products like fresh pasta and ravioli. By maintaining the appropriate temperature, these gels help in extending the shelf life of pasta products, ensuring they reach consumers in optimal condition. In the bionic vegetarian sector, which includes plant-based meat alternatives, thermal gels play a crucial role in maintaining the texture and flavor of products. These gels help in preserving the integrity of the ingredients, ensuring that the final product meets consumer expectations in terms of taste and quality. The aquatic products segment, which includes fish and seafood, also relies heavily on thermal gels to maintain freshness and prevent spoilage. These gels help in regulating the temperature during transportation and storage, ensuring that the products remain safe for consumption. In the canned products sector, thermal gels are used to maintain the quality and safety of products such as canned fruits, vegetables, and soups. By regulating the temperature, these gels help in preventing spoilage and ensuring that the products remain safe for consumption. Finally, in the "other" category, thermal gels find application in a wide range of food products, each with its unique requirements and challenges. From dairy products to baked goods, thermal gels play a crucial role in maintaining the quality and safety of food products, ensuring they reach consumers in optimal condition. In conclusion, the Global Food Grade Thermal Gel Market plays a vital role in ensuring the safety and quality of a wide range of food products. By regulating the temperature during transportation and storage, these gels help in preventing spoilage and ensuring that products reach consumers in optimal condition. As consumer awareness of food safety and quality continues to rise, the demand for food grade thermal gels is expected to grow, driving innovation and expansion within the market.

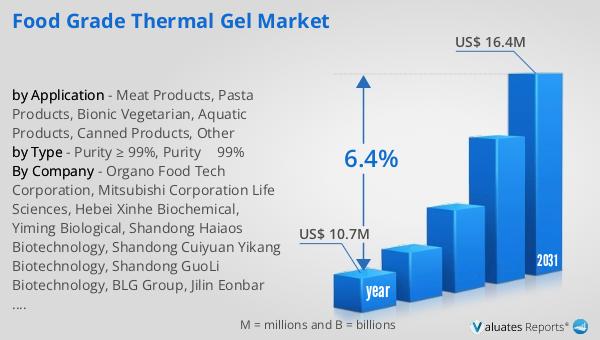

Global Food Grade Thermal Gel Market Outlook:

The worldwide market for Food Grade Thermal Gel was valued at $10.7 million in 2024, and it is anticipated to expand to a revised size of $16.4 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth trajectory underscores the increasing demand for effective temperature control solutions in the food industry, driven by the rising consumer awareness of food safety and quality. As the market evolves, companies are investing in research and development to enhance the performance and safety of their products, ensuring they meet the stringent regulations set by food safety authorities worldwide. The projected growth of the market highlights the importance of food grade thermal gels in maintaining the quality and safety of food products during storage and transportation. As the demand for convenience foods continues to rise, the need for effective temperature control solutions is expected to grow, driving innovation and expansion within the market. Companies operating in this space must remain committed to innovation and transparency, ensuring they meet the evolving needs of their customers and maintain a competitive edge in the industry. The market outlook for Food Grade Thermal Gel is promising, with significant growth opportunities for companies that can effectively meet the demands of the market.

| Report Metric | Details |

| Report Name | Food Grade Thermal Gel Market |

| Accounted market size in year | US$ 10.7 million |

| Forecasted market size in 2031 | US$ 16.4 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Organo Food Tech Corporation, Mitsubishi Corporation Life Sciences, Hebei Xinhe Biochemical, Yiming Biological, Shandong Haiaos Biotechnology, Shandong Cuiyuan Yikang Biotechnology, Shandong GuoLi Biotechnology, BLG Group, Jilin Eonbar Biology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |