What is Global Gel Card Market?

The Global Gel Card Market is a specialized segment within the medical diagnostics industry, focusing on the production and distribution of gel cards used primarily for blood typing and compatibility testing. These cards are integral in laboratories and healthcare settings for their efficiency and accuracy in detecting blood group antigens and antibodies. The gel card technology simplifies the process of blood testing by using a gel matrix that allows for the separation of red blood cells based on their specific properties. This method is not only more reliable but also reduces the risk of human error compared to traditional methods. The market for gel cards is driven by the increasing demand for safe blood transfusions, advancements in medical technology, and the growing prevalence of chronic diseases that require regular blood testing. As healthcare systems worldwide continue to evolve, the need for precise and efficient diagnostic tools like gel cards is expected to rise, making this market a critical component of modern medical diagnostics. The global reach of this market is expanding, with significant growth opportunities in emerging economies where healthcare infrastructure is rapidly developing.

Grouping Gel Card, Crossmatch Gel Card, Antibody Screening Gel Card, Others in the Global Gel Card Market:

The Global Gel Card Market is segmented into various types based on their specific applications, including Grouping Gel Card, Crossmatch Gel Card, Antibody Screening Gel Card, and others. Grouping Gel Cards are primarily used for determining the blood group of an individual. This is a crucial step in ensuring that patients receive compatible blood transfusions, which can prevent adverse reactions. These cards work by mixing a small sample of blood with specific reagents that react with antigens on the surface of red blood cells. The gel matrix then helps in visualizing the agglutination, which indicates the blood group. Crossmatch Gel Cards are used to ensure compatibility between donor and recipient blood before a transfusion. This process involves mixing donor red blood cells with recipient serum to check for any adverse reactions. The gel card technology allows for a more streamlined and accurate crossmatching process, reducing the risk of transfusion-related complications. Antibody Screening Gel Cards are designed to detect unexpected antibodies in a patient's blood. These antibodies can cause serious reactions if not identified before a transfusion. The gel card method provides a sensitive and specific way to screen for these antibodies, ensuring patient safety. Other types of gel cards may include those used for specific antigen testing or for educational purposes in medical training. Each type of gel card plays a vital role in the overall blood testing and transfusion process, contributing to the safety and efficacy of medical treatments. The versatility and reliability of gel card technology make it an indispensable tool in modern healthcare, supporting a wide range of diagnostic and therapeutic applications. As the demand for precise and efficient diagnostic tools continues to grow, the Global Gel Card Market is poised for significant expansion, driven by technological advancements and the increasing need for safe blood transfusions worldwide.

Hospital, Clinic, Others in the Global Gel Card Market:

The usage of gel cards in hospitals, clinics, and other healthcare settings is a testament to their importance in modern medical diagnostics. In hospitals, gel cards are primarily used in blood banks and transfusion services. They play a crucial role in ensuring that patients receive compatible blood transfusions, which is vital for patient safety. The accuracy and efficiency of gel card technology help reduce the risk of transfusion-related complications, making them an essential tool in hospital laboratories. In addition to blood typing and crossmatching, gel cards are also used for antibody screening, which is critical in identifying unexpected antibodies that could cause adverse reactions during a transfusion. Clinics, which often have limited resources compared to larger hospitals, benefit greatly from the simplicity and reliability of gel card technology. The ease of use and minimal training required for gel card testing make it an ideal choice for clinics that need to perform blood typing and compatibility testing quickly and accurately. This is particularly important in emergency situations where time is of the essence. The portability and compact design of gel cards also make them suitable for use in remote or resource-limited settings, where access to advanced laboratory equipment may be limited. Beyond hospitals and clinics, gel cards are used in various other settings, including research laboratories and educational institutions. In research, gel cards are used to study blood group antigens and antibodies, contributing to the development of new diagnostic and therapeutic approaches. In educational settings, gel cards serve as a valuable teaching tool, helping students understand the principles of blood typing and transfusion medicine. The versatility of gel card technology extends its applications beyond traditional healthcare settings, highlighting its importance in advancing medical knowledge and improving patient care. As the demand for accurate and efficient diagnostic tools continues to grow, the usage of gel cards in hospitals, clinics, and other settings is expected to increase, supporting the ongoing evolution of healthcare systems worldwide.

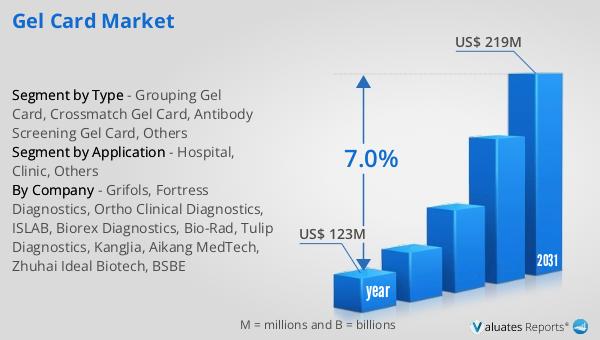

Global Gel Card Market Outlook:

In 2024, the global market for Gel Cards was valued at approximately $123 million. This market is anticipated to grow significantly, reaching an estimated value of $219 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.0% over the forecast period. The expansion of the Gel Card Market is driven by several factors, including the increasing demand for safe and efficient blood transfusion procedures, advancements in medical technology, and the rising prevalence of chronic diseases that necessitate regular blood testing. As healthcare systems around the world continue to evolve, the need for precise and reliable diagnostic tools like gel cards is becoming increasingly important. The market's growth is also supported by the expanding healthcare infrastructure in emerging economies, where there is a growing emphasis on improving patient care and safety. The projected growth of the Gel Card Market reflects the critical role that these diagnostic tools play in modern healthcare, providing accurate and efficient solutions for blood typing and compatibility testing. As the market continues to expand, it is expected to offer significant opportunities for innovation and development, further enhancing the capabilities of gel card technology and its applications in various healthcare settings.

| Report Metric | Details |

| Report Name | Gel Card Market |

| Accounted market size in year | US$ 123 million |

| Forecasted market size in 2031 | US$ 219 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Grifols, Fortress Diagnostics, Ortho Clinical Diagnostics, ISLAB, Biorex Diagnostics, Bio-Rad, Tulip Diagnostics, KangJia, Aikang MedTech, Zhuhai Ideal Biotech, BSBE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |