What is Global Inline Moisture Analyzer Market?

The Global Inline Moisture Analyzer Market refers to the industry focused on devices that measure the moisture content in various materials as they move through production processes. These analyzers are crucial in industries where moisture levels can significantly impact product quality, efficiency, and safety. Inline moisture analyzers are integrated directly into production lines, allowing for real-time monitoring and control of moisture levels. This capability helps manufacturers maintain consistent product quality, reduce waste, and optimize energy use. The market for these devices is driven by the increasing demand for high-quality products and the need for efficient manufacturing processes. Industries such as food processing, pharmaceuticals, chemicals, and construction materials rely heavily on these analyzers to ensure their products meet stringent quality standards. As technology advances, these devices are becoming more sophisticated, offering features like wireless connectivity and advanced data analytics, which further enhance their utility in modern manufacturing environments. The global market for inline moisture analyzers is expected to grow as more industries recognize the benefits of precise moisture control in their production processes.

Handheld Moisture Analyzer, Desktop Moisture Analyzer in the Global Inline Moisture Analyzer Market:

Handheld and desktop moisture analyzers are two types of devices within the Global Inline Moisture Analyzer Market, each serving distinct purposes and offering unique advantages. Handheld moisture analyzers are portable devices designed for quick and easy moisture measurement in various settings. They are particularly useful in situations where mobility is essential, such as fieldwork or when testing multiple locations within a facility. These devices are typically battery-operated and feature user-friendly interfaces, making them accessible to operators without extensive technical training. Handheld analyzers are commonly used in industries like agriculture, construction, and food processing, where on-the-spot moisture readings can inform immediate decisions and adjustments. Their portability and ease of use make them a valuable tool for quality control and assurance in dynamic environments. On the other hand, desktop moisture analyzers are stationary devices that offer more comprehensive and precise moisture analysis. These analyzers are typically used in laboratory settings or production environments where detailed moisture data is required. Desktop models often feature advanced technologies such as infrared or microwave sensors, which provide highly accurate and reliable measurements. They are capable of analyzing a wide range of materials, from powders and granules to liquids and pastes. The precision and versatility of desktop moisture analyzers make them ideal for industries that require stringent quality control, such as pharmaceuticals, chemicals, and food manufacturing. These devices often come with sophisticated software that allows for data logging, analysis, and reporting, providing valuable insights into moisture trends and helping manufacturers optimize their processes. Both handheld and desktop moisture analyzers play crucial roles in the Global Inline Moisture Analyzer Market, catering to different needs and applications. While handheld devices offer flexibility and convenience, desktop models provide accuracy and depth of analysis. The choice between the two depends on the specific requirements of the industry and the nature of the materials being analyzed. As technology continues to evolve, both types of analyzers are expected to incorporate more advanced features, such as connectivity with other devices and systems, enhanced data processing capabilities, and improved user interfaces. These advancements will further enhance their utility and effectiveness in various industrial applications, driving growth in the Global Inline Moisture Analyzer Market.

Wood Processing, Food, Paper, Pet Food, Tobacco, Others in the Global Inline Moisture Analyzer Market:

The Global Inline Moisture Analyzer Market finds extensive application across various industries, each with unique requirements and challenges. In the wood processing industry, moisture content is a critical factor that affects the quality and durability of wood products. Inline moisture analyzers help manufacturers monitor and control moisture levels during production, ensuring that wood products meet industry standards and customer expectations. By providing real-time data, these analyzers enable manufacturers to make immediate adjustments, reducing waste and improving efficiency. In the food industry, moisture content plays a vital role in determining the shelf life, texture, and taste of products. Inline moisture analyzers are used to ensure that food products have the right moisture levels, which is crucial for maintaining quality and safety. These devices help manufacturers optimize drying processes, reduce energy consumption, and minimize product spoilage. The ability to monitor moisture levels in real-time allows for better control over production processes, leading to consistent product quality and reduced operational costs. The paper industry also relies heavily on inline moisture analyzers to maintain product quality. Moisture content affects the strength, weight, and printability of paper products. By using inline analyzers, manufacturers can ensure that paper products meet the required specifications, reducing the risk of defects and improving customer satisfaction. These devices help optimize drying processes, leading to energy savings and increased production efficiency. In the pet food industry, moisture content is crucial for ensuring product safety and quality. Inline moisture analyzers help manufacturers maintain the right moisture levels, which is essential for preventing microbial growth and ensuring the nutritional value of pet food products. By providing real-time data, these analyzers enable manufacturers to make necessary adjustments during production, ensuring that products meet industry standards and customer expectations. The tobacco industry also benefits from the use of inline moisture analyzers. Moisture content affects the flavor, burn rate, and shelf life of tobacco products. By using these analyzers, manufacturers can ensure that tobacco products have the right moisture levels, leading to improved product quality and customer satisfaction. Inline analyzers help optimize drying processes, reduce waste, and improve production efficiency. Other industries, such as chemicals and pharmaceuticals, also rely on inline moisture analyzers to ensure product quality and consistency. These devices provide valuable data that helps manufacturers optimize production processes, reduce waste, and improve efficiency. As more industries recognize the benefits of precise moisture control, the demand for inline moisture analyzers is expected to grow, driving further advancements in technology and applications.

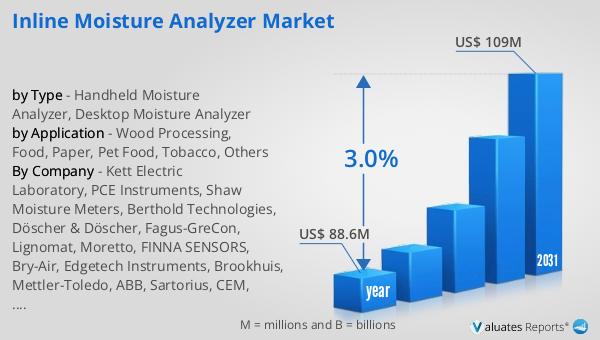

Global Inline Moisture Analyzer Market Outlook:

The global market for inline moisture analyzers was valued at approximately $88.6 million in 2024. This market is anticipated to expand, reaching an estimated size of $109 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.0% over the forecast period. This steady growth can be attributed to the increasing demand for precise moisture measurement across various industries, including food processing, pharmaceuticals, and construction materials. As manufacturers strive to improve product quality and production efficiency, the adoption of inline moisture analyzers is expected to rise. These devices offer real-time monitoring and control of moisture levels, enabling manufacturers to maintain consistent product quality and reduce waste. The market's growth is also driven by advancements in technology, which have led to the development of more sophisticated and user-friendly analyzers. Features such as wireless connectivity, advanced data analytics, and improved sensor accuracy are enhancing the utility of these devices in modern manufacturing environments. As industries continue to recognize the benefits of precise moisture control, the global market for inline moisture analyzers is poised for continued growth, offering significant opportunities for manufacturers and suppliers in this sector.

| Report Metric | Details |

| Report Name | Inline Moisture Analyzer Market |

| Accounted market size in year | US$ 88.6 million |

| Forecasted market size in 2031 | US$ 109 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kett Electric Laboratory, PCE Instruments, Shaw Moisture Meters, Berthold Technologies, Döscher & Döscher, Fagus-GreCon, Lignomat, Moretto, FINNA SENSORS, Bry-Air, Edgetech Instruments, Brookhuis, Mettler-Toledo, ABB, Sartorius, CEM, Process Sensors, MoistTech, Ametek, Cosa Xentaur |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |