What is Global Mesh Pad Demister Market?

The Global Mesh Pad Demister Market is a specialized segment within the industrial equipment sector, focusing on devices designed to remove liquid droplets from gas streams. These demisters are crucial in various industries where gas-liquid separation is necessary to ensure the purity of the gas and prevent equipment damage or inefficiencies. Mesh pad demisters are typically made from materials like metal or plastic and are installed in process equipment such as scrubbers, separators, and distillation columns. They work by providing a surface for liquid droplets to coalesce and drain back into the liquid phase, thus preventing them from being carried over with the gas. The demand for mesh pad demisters is driven by the need for efficient separation processes in industries such as chemical manufacturing, oil and gas, pharmaceuticals, and more. As industries continue to seek ways to improve operational efficiency and product quality, the market for mesh pad demisters is expected to grow, driven by technological advancements and increasing industrial activities worldwide. The market's growth is also supported by stringent environmental regulations that require industries to minimize emissions and waste, further boosting the adoption of effective separation technologies like mesh pad demisters.

Metal Mesh Pad Demister, Plastic Mesh Pad Demister, Others in the Global Mesh Pad Demister Market:

Metal Mesh Pad Demisters are a popular choice in the Global Mesh Pad Demister Market due to their durability and efficiency in high-temperature and high-pressure environments. These demisters are typically made from stainless steel or other corrosion-resistant metals, making them suitable for use in harsh industrial conditions. Metal mesh pad demisters are commonly used in the petrochemical industry, where they help in the separation of liquid hydrocarbons from gas streams, ensuring the purity of the final product and protecting downstream equipment from damage. Their robust construction allows them to withstand the rigors of continuous operation, making them a reliable choice for industries that require consistent performance. On the other hand, Plastic Mesh Pad Demisters are favored for their lightweight and cost-effective nature. Made from materials like polypropylene or PTFE, these demisters are ideal for applications where corrosion resistance is a priority, such as in chemical processing plants. Plastic mesh pad demisters are particularly useful in environments where metal corrosion could be a concern, offering a long-lasting solution without the risk of rust or degradation. They are also easier to handle and install due to their lighter weight, making them a practical choice for many industries. In addition to metal and plastic options, the market also includes other types of mesh pad demisters, which may be made from composite materials or specialized alloys to meet specific industrial needs. These alternatives are designed to offer a balance between the strength of metal and the corrosion resistance of plastic, providing a versatile solution for complex separation challenges. The choice of material for a mesh pad demister often depends on the specific requirements of the application, including factors such as temperature, pressure, chemical compatibility, and cost considerations. As industries continue to evolve and face new challenges, the demand for innovative and efficient mesh pad demister solutions is expected to grow, driving further advancements in material science and engineering.

Chemical Industry, Pharmaceutical, Petro, Papermaking, Others in the Global Mesh Pad Demister Market:

The Global Mesh Pad Demister Market finds extensive usage across various industries, each with its unique requirements and challenges. In the chemical industry, mesh pad demisters are essential for ensuring the purity of chemical products by effectively separating liquid droplets from gas streams. This separation is crucial in processes such as distillation, where the presence of liquid contaminants can affect the quality and yield of the final product. By using mesh pad demisters, chemical manufacturers can achieve higher product purity and reduce the risk of equipment fouling, leading to improved operational efficiency and cost savings. In the pharmaceutical industry, the need for high-purity products is even more critical, as any contamination can compromise the safety and efficacy of pharmaceutical products. Mesh pad demisters play a vital role in maintaining the integrity of pharmaceutical processes by preventing liquid carryover and ensuring that only pure gas is used in production. This is particularly important in processes such as gas chromatography and other analytical techniques, where even trace amounts of liquid can skew results and affect product quality. The petrochemical industry also relies heavily on mesh pad demisters to separate liquid hydrocarbons from gas streams, ensuring the purity of the final product and protecting downstream equipment from damage. In this industry, the ability to efficiently separate liquids from gases is crucial for maintaining product quality and preventing costly equipment failures. Mesh pad demisters are used in various stages of petrochemical processing, from crude oil refining to natural gas processing, helping to optimize production and reduce environmental impact. In the papermaking industry, mesh pad demisters are used to remove water droplets from steam, ensuring that the steam used in the drying process is free from contaminants. This is important for maintaining the quality of the paper and preventing defects that can arise from the presence of liquid impurities. By using mesh pad demisters, papermakers can achieve consistent product quality and reduce the risk of equipment damage caused by liquid carryover. Other industries that benefit from the use of mesh pad demisters include food and beverage, power generation, and wastewater treatment, where the need for efficient gas-liquid separation is critical for maintaining product quality and operational efficiency. As industries continue to seek ways to improve their processes and reduce environmental impact, the demand for effective separation technologies like mesh pad demisters is expected to grow, driving further innovation and development in this market.

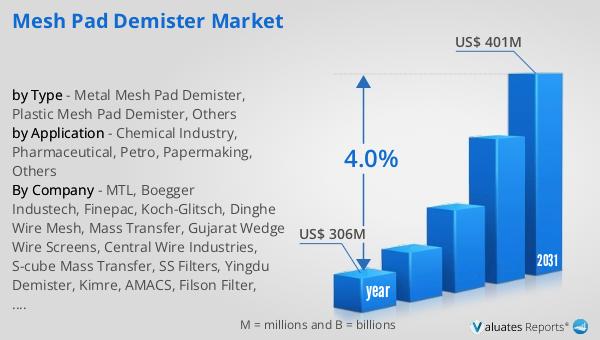

Global Mesh Pad Demister Market Outlook:

The global market for Mesh Pad Demisters was valued at approximately $306 million in 2024, and it is anticipated to expand to a revised size of around $401 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. This steady growth can be attributed to the increasing demand for efficient separation technologies across various industries, including chemical manufacturing, pharmaceuticals, petrochemicals, and more. As industries continue to prioritize operational efficiency and product quality, the adoption of mesh pad demisters is expected to rise, driven by their ability to effectively separate liquid droplets from gas streams. Additionally, stringent environmental regulations and the need to minimize emissions and waste are further propelling the demand for advanced separation solutions like mesh pad demisters. The market's growth is also supported by technological advancements and innovations in material science, which are leading to the development of more efficient and durable demister solutions. As a result, the Global Mesh Pad Demister Market is poised for continued expansion, offering significant opportunities for manufacturers and suppliers in this sector.

| Report Metric | Details |

| Report Name | Mesh Pad Demister Market |

| Accounted market size in year | US$ 306 million |

| Forecasted market size in 2031 | US$ 401 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTL, Boegger Industech, Finepac, Koch-Glitsch, Dinghe Wire Mesh, Mass Transfer, Gujarat Wedge Wire Screens, Central Wire Industries, S-cube Mass Transfer, SS Filters, Yingdu Demister, Kimre, AMACS, Filson Filter, Sulzer, International Wirenetting Industries, Koch Industries, Sulzer Chemtech, MECS, FLEXICHEM, RVT Process Equipment, Monroe Environmental, Munters, Padana Clean Air Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |