What is Global Industrial Diaphragm Pump Market?

The Global Industrial Diaphragm Pump Market is a significant segment within the broader industrial equipment sector, focusing on the production and distribution of diaphragm pumps. These pumps are essential for various industries due to their ability to handle a wide range of fluids, including those that are viscous, abrasive, or corrosive. Diaphragm pumps operate using a flexible diaphragm that moves back and forth, creating a vacuum to draw in and expel fluids. This mechanism makes them highly efficient and reliable for transferring liquids without the risk of leakage, which is crucial in industries where contamination must be avoided. The market is driven by the increasing demand for efficient fluid handling solutions across diverse sectors such as water treatment, oil and gas, chemicals, and food and beverages. Additionally, technological advancements and innovations in pump design and materials are enhancing the performance and durability of diaphragm pumps, further boosting their adoption globally. As industries continue to expand and modernize, the need for robust and versatile pumping solutions like diaphragm pumps is expected to grow, making this market a vital component of industrial operations worldwide.

Single Diaphragm Pump, Double Diaphragm Pump in the Global Industrial Diaphragm Pump Market:

In the realm of the Global Industrial Diaphragm Pump Market, two primary types of diaphragm pumps stand out: Single Diaphragm Pumps and Double Diaphragm Pumps. Single Diaphragm Pumps are designed with a single diaphragm that moves back and forth to create a vacuum, drawing in and expelling fluids. These pumps are typically used in applications where the fluid being pumped is not highly abrasive or corrosive, as the single diaphragm design may not provide the same level of durability and protection as its double counterpart. Single Diaphragm Pumps are often favored for their simplicity and cost-effectiveness, making them suitable for less demanding applications where budget constraints are a consideration. On the other hand, Double Diaphragm Pumps feature two diaphragms that work in tandem, providing a more robust and reliable pumping solution. This design allows for the handling of more challenging fluids, including those that are abrasive, corrosive, or contain solids. The dual diaphragm setup ensures that even if one diaphragm fails, the pump can continue to operate, providing an added layer of reliability and safety. Double Diaphragm Pumps are widely used in industries such as chemicals, pharmaceuticals, and mining, where the handling of aggressive or hazardous fluids is common. The versatility of Double Diaphragm Pumps makes them a preferred choice for applications requiring high levels of precision and safety. Both Single and Double Diaphragm Pumps are integral to the Global Industrial Diaphragm Pump Market, each serving distinct needs and applications. The choice between the two often depends on the specific requirements of the application, including the nature of the fluid being pumped, the required flow rate, and the operating environment. As industries continue to evolve and demand more efficient and reliable fluid handling solutions, the role of both Single and Double Diaphragm Pumps in the market is expected to remain significant. Manufacturers are continually innovating to improve the performance, efficiency, and durability of these pumps, ensuring they meet the ever-changing needs of industrial applications. This ongoing innovation is crucial for maintaining the competitiveness of diaphragm pumps in the global market, as industries seek to optimize their operations and reduce downtime. The Global Industrial Diaphragm Pump Market is thus characterized by a dynamic interplay between technological advancements, industry demands, and the need for sustainable and efficient fluid handling solutions.

Automotive Industry, Construction Industry, Road Construction, Mining, Chemical Industry, Others in the Global Industrial Diaphragm Pump Market:

The Global Industrial Diaphragm Pump Market finds extensive usage across various industries, each with unique requirements and challenges. In the Automotive Industry, diaphragm pumps are crucial for handling fluids such as oils, coolants, and fuels. Their ability to manage viscous and abrasive fluids without leakage makes them ideal for automotive applications, where precision and reliability are paramount. In the Construction Industry, diaphragm pumps are used for dewatering, transferring concrete, and handling other construction materials. Their robust design allows them to operate efficiently in harsh environments, making them indispensable for construction projects. Road Construction also benefits from diaphragm pumps, particularly in the application of asphalt and other road-building materials. The pumps' ability to handle high-viscosity fluids ensures that materials are applied evenly and efficiently, contributing to the quality and durability of road surfaces. In the Mining Industry, diaphragm pumps are used for dewatering mines, transferring slurry, and handling other challenging fluids. Their durability and resistance to abrasive materials make them ideal for the demanding conditions of mining operations. The Chemical Industry relies heavily on diaphragm pumps for transferring corrosive and hazardous chemicals. The pumps' leak-proof design ensures safe and efficient handling of these substances, minimizing the risk of spills and contamination. Beyond these industries, diaphragm pumps are also used in sectors such as food and beverage, pharmaceuticals, and water treatment. In the food and beverage industry, they are used for transferring ingredients and finished products, ensuring hygiene and preventing contamination. In pharmaceuticals, diaphragm pumps are used for precise dosing and transfer of sensitive fluids, maintaining the integrity of the products. In water treatment, they are used for dosing chemicals and transferring water, playing a crucial role in ensuring clean and safe water supply. The versatility and reliability of diaphragm pumps make them a preferred choice across these diverse applications, driving their demand in the Global Industrial Diaphragm Pump Market. As industries continue to seek efficient and sustainable solutions for fluid handling, the role of diaphragm pumps is expected to grow, further solidifying their position in the global market.

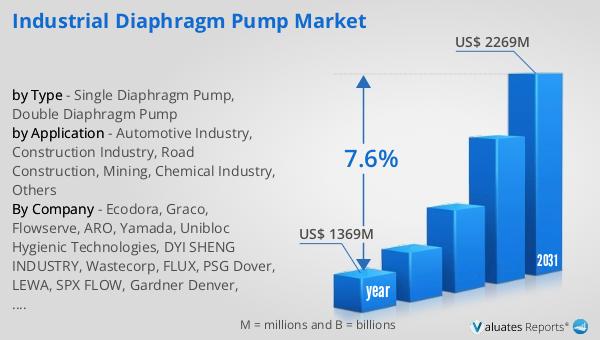

Global Industrial Diaphragm Pump Market Outlook:

The outlook for the Global Industrial Diaphragm Pump Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1369 million. By 2031, it is expected to reach a revised size of around US$ 2269 million, reflecting a compound annual growth rate (CAGR) of 7.6% during the forecast period. This growth is driven by the increasing demand for efficient and reliable fluid handling solutions across various industries. As industries continue to expand and modernize, the need for robust and versatile pumping solutions like diaphragm pumps is expected to grow. The market's expansion is also supported by technological advancements and innovations in pump design and materials, which enhance the performance and durability of diaphragm pumps. These factors, combined with the growing emphasis on sustainability and efficiency in industrial operations, are expected to drive the demand for diaphragm pumps in the coming years. The Global Industrial Diaphragm Pump Market is thus poised for significant growth, offering opportunities for manufacturers and stakeholders to capitalize on the increasing demand for advanced fluid handling solutions.

| Report Metric | Details |

| Report Name | Industrial Diaphragm Pump Market |

| Accounted market size in year | US$ 1369 million |

| Forecasted market size in 2031 | US$ 2269 million |

| CAGR | 7.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ecodora, Graco, Flowserve, ARO, Yamada, Unibloc Hygienic Technologies, DYI SHENG INDUSTRY, Wastecorp, FLUX, PSG Dover, LEWA, SPX FLOW, Gardner Denver, ProMinent, Alemite, Wilden, ABEL, Roto Pumps, Nirmala pumps and Equipments, SEEPEX |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |