What is Global Radiation Hardened Camera Market?

The Global Radiation Hardened Camera Market refers to a specialized segment of the camera industry that focuses on developing cameras capable of withstanding high levels of radiation. These cameras are essential in environments where radiation exposure is a concern, such as space exploration, nuclear power plants, and military applications. Radiation can severely damage electronic components, so these cameras are designed with materials and technologies that protect their internal systems from radiation-induced failures. This market is driven by the increasing demand for reliable imaging solutions in harsh environments, where standard cameras would fail. The development of radiation-hardened cameras involves advanced engineering to ensure durability and functionality under extreme conditions. As technology advances, the market continues to evolve, offering more sophisticated and robust solutions to meet the growing needs of industries that operate in radiation-prone areas. The market's growth is fueled by the ongoing investments in space missions, nuclear energy projects, and defense sectors, which require high-performance imaging equipment to ensure safety and operational efficiency.

Analog, Digital in the Global Radiation Hardened Camera Market:

In the Global Radiation Hardened Camera Market, cameras are primarily categorized into two types: analog and digital. Analog radiation-hardened cameras are traditional devices that capture images using continuous signals. These cameras are known for their simplicity and reliability, making them suitable for environments where digital technology might be too complex or vulnerable to radiation damage. Analog cameras convert light into electrical signals, which are then transmitted over coaxial cables to a display or recording device. They are often used in applications where real-time monitoring is crucial, such as in nuclear facilities or military operations. Despite the rise of digital technology, analog cameras remain relevant due to their robustness and ease of use in high-radiation environments. On the other hand, digital radiation-hardened cameras represent the modern evolution of imaging technology. These cameras capture images using digital sensors, which convert light into digital data. This data can be easily processed, stored, and transmitted, offering greater flexibility and functionality compared to analog systems. Digital cameras provide higher resolution images, better image processing capabilities, and the ability to integrate with other digital systems. They are increasingly preferred in applications where detailed imaging and data analysis are required, such as in space exploration and scientific research. The transition from analog to digital in the radiation-hardened camera market is driven by the need for more advanced imaging solutions that can handle complex tasks and provide detailed insights. However, digital cameras must be carefully designed to withstand radiation, as their electronic components are more susceptible to damage. Manufacturers employ various techniques, such as shielding and radiation-tolerant materials, to enhance the durability of digital cameras in harsh environments. The choice between analog and digital radiation-hardened cameras depends on the specific requirements of the application, including factors like image quality, data processing needs, and environmental conditions. Both types of cameras play a crucial role in ensuring safety and efficiency in industries where radiation exposure is a significant concern. As technology continues to advance, the market is likely to see further innovations in both analog and digital radiation-hardened cameras, offering improved performance and reliability for a wide range of applications.

In-air Application, Underwater Application in the Global Radiation Hardened Camera Market:

The Global Radiation Hardened Camera Market finds significant usage in various applications, including in-air and underwater environments. In-air applications primarily involve the use of radiation-hardened cameras in aerospace and defense sectors. These cameras are crucial for capturing high-quality images and videos in space missions, where radiation levels are extremely high. They are used in satellites, space probes, and other spacecraft to monitor and document space activities, conduct scientific research, and ensure the safety of astronauts. The ability to withstand radiation ensures that these cameras can operate effectively in the harsh conditions of outer space, providing reliable imaging solutions for critical missions. In the defense sector, radiation-hardened cameras are used in military aircraft and drones to capture real-time images and videos for surveillance, reconnaissance, and intelligence gathering. Their durability and reliability make them ideal for use in high-radiation environments, such as nuclear test sites or areas affected by nuclear fallout. Underwater applications of radiation-hardened cameras are equally important, particularly in the field of nuclear energy. These cameras are used in nuclear power plants to monitor underwater reactors and other submerged components. The ability to withstand radiation and operate effectively underwater makes them essential tools for ensuring the safety and efficiency of nuclear operations. They provide real-time imaging and monitoring capabilities, allowing operators to detect and address potential issues before they escalate. Additionally, radiation-hardened cameras are used in underwater research and exploration, where they capture images and videos of marine life and underwater environments in areas with high radiation levels. Their robust design and advanced imaging capabilities enable researchers to conduct studies and gather data in challenging conditions, contributing to our understanding of underwater ecosystems and the impact of radiation on marine life. Overall, the use of radiation-hardened cameras in in-air and underwater applications highlights their versatility and importance in industries where radiation exposure is a significant concern. These cameras provide reliable imaging solutions that enhance safety, efficiency, and knowledge in environments where standard cameras would fail.

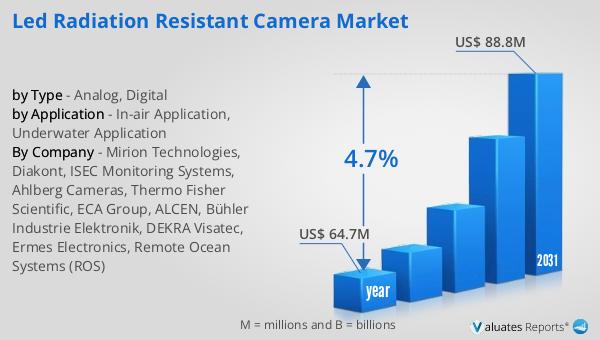

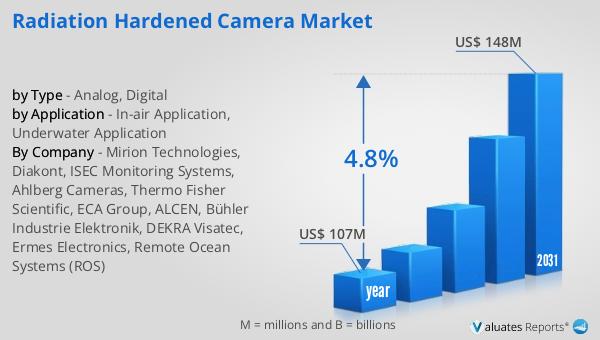

Global Radiation Hardened Camera Market Outlook:

The global market for radiation-hardened cameras was valued at approximately $107 million in 2024. This market is anticipated to grow steadily, reaching an estimated value of $148 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. The increasing demand for radiation-hardened cameras is driven by their critical role in various industries, including aerospace, defense, and nuclear energy. These cameras are essential for capturing high-quality images and videos in environments with high radiation levels, where standard cameras would be ineffective. The market's growth is supported by ongoing investments in space exploration, military applications, and nuclear energy projects, all of which require reliable imaging solutions to ensure safety and operational efficiency. As technology continues to advance, the market is expected to see further innovations in radiation-hardened camera design and functionality, offering improved performance and reliability for a wide range of applications. The steady growth of this market reflects the increasing importance of radiation-hardened cameras in industries where radiation exposure is a significant concern.

| Report Metric | Details |

| Report Name | Radiation Hardened Camera Market |

| Accounted market size in year | US$ 107 million |

| Forecasted market size in 2031 | US$ 148 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mirion Technologies, Diakont, ISEC Monitoring Systems, Ahlberg Cameras, Thermo Fisher Scientific, ECA Group, ALCEN, Bühler Industrie Elektronik, DEKRA Visatec, Ermes Electronics, Remote Ocean Systems (ROS) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |