What is Global Composite Plier Market?

The Global Composite Plier Market refers to the worldwide industry focused on the production, distribution, and sale of composite pliers. These tools are essential in various industries due to their unique construction, which combines different materials to enhance performance, durability, and efficiency. Composite pliers are typically made from a blend of materials such as fiberglass, carbon fiber, and other high-strength polymers, which provide them with superior strength and resistance to wear and tear compared to traditional metal pliers. This market encompasses a wide range of plier types, including needle-nose, diagonal, and slip-joint pliers, each designed for specific applications. The demand for composite pliers is driven by their lightweight nature, corrosion resistance, and ability to withstand high temperatures, making them ideal for use in harsh environments. As industries continue to seek tools that offer improved performance and longevity, the Global Composite Plier Market is expected to see significant growth, driven by advancements in material science and manufacturing technologies. This growth is further supported by the increasing adoption of composite materials across various sectors, highlighting the importance of innovation in meeting the evolving needs of modern industries.

Adjustable, Not Adjustable in the Global Composite Plier Market:

In the Global Composite Plier Market, pliers can be categorized into two main types: adjustable and not adjustable. Adjustable composite pliers are designed with a mechanism that allows the user to modify the jaw width to accommodate different sizes of objects. This feature makes them highly versatile and suitable for a wide range of applications, from gripping and twisting to cutting and bending. The adjustability is typically achieved through a pivot point or a sliding mechanism, which can be easily manipulated to change the jaw size. These pliers are particularly useful in situations where the user needs to work with various sizes of materials or components, as they eliminate the need for multiple tools. On the other hand, not adjustable composite pliers have a fixed jaw width, which means they are designed for specific tasks and applications. While they may lack the versatility of their adjustable counterparts, not adjustable pliers often offer greater precision and stability, making them ideal for tasks that require a consistent grip or cut. The choice between adjustable and not adjustable composite pliers largely depends on the specific needs of the user and the nature of the task at hand. In industries such as automotive and aerospace, where precision and reliability are paramount, not adjustable pliers are often preferred for their ability to deliver consistent results. However, in fields like mechanical engineering and electrical work, where the range of tasks can vary significantly, adjustable pliers are valued for their adaptability and convenience. The Global Composite Plier Market is characterized by a diverse range of products, each designed to meet the specific demands of different industries and applications. Manufacturers in this market are continually innovating to improve the functionality and performance of both adjustable and not adjustable pliers, incorporating advanced materials and ergonomic designs to enhance user comfort and efficiency. As a result, the market offers a wide array of options for consumers, from high-end professional-grade tools to more affordable options for casual users. This diversity ensures that there is a composite plier available for virtually every need, whether it be in a professional setting or for personal use. The ongoing advancements in material technology and manufacturing processes are expected to further expand the capabilities of composite pliers, offering even greater performance and durability in the future. As industries continue to evolve and demand more specialized tools, the Global Composite Plier Market will play a crucial role in providing the solutions needed to meet these challenges.

Mechanical Engineering, Automotive Industry, Aerospace, Oil And Gas, Chemical Industry, Medical Technology, Electrical Industry in the Global Composite Plier Market:

The Global Composite Plier Market finds extensive usage across various industries due to the unique properties and advantages offered by composite materials. In mechanical engineering, composite pliers are valued for their strength and durability, which make them ideal for tasks that involve heavy-duty gripping, bending, and cutting. Their lightweight nature also reduces user fatigue, allowing engineers to work more efficiently over extended periods. In the automotive industry, composite pliers are used for assembling and disassembling components, as well as for maintenance and repair tasks. Their corrosion resistance is particularly beneficial in this sector, where exposure to oils, chemicals, and other harsh substances is common. In the aerospace industry, the demand for lightweight and high-strength tools is critical, and composite pliers meet these requirements by offering superior performance without adding unnecessary weight. This is crucial in an industry where every gram counts towards fuel efficiency and overall performance. The oil and gas industry also benefits from the use of composite pliers, as they are capable of withstanding extreme temperatures and corrosive environments, making them suitable for use in offshore and onshore drilling operations. In the chemical industry, composite pliers are used for handling and manipulating various materials and components, thanks to their resistance to chemical corrosion and their ability to maintain structural integrity under harsh conditions. Medical technology is another area where composite pliers are gaining traction, as they offer precision and reliability in delicate procedures, along with the added benefit of being non-magnetic, which is essential in environments where magnetic interference must be minimized. Finally, in the electrical industry, composite pliers are used for tasks such as cutting and stripping wires, as well as for assembling and disassembling electrical components. Their non-conductive properties make them a safer choice for electricians working with live circuits, reducing the risk of electrical shock. Overall, the versatility and performance of composite pliers make them an invaluable tool across a wide range of industries, each benefiting from the unique advantages offered by composite materials.

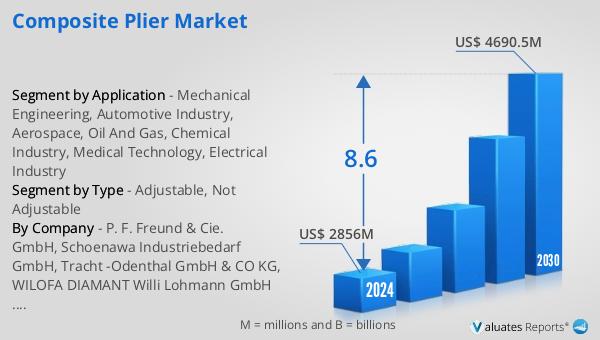

Global Composite Plier Market Outlook:

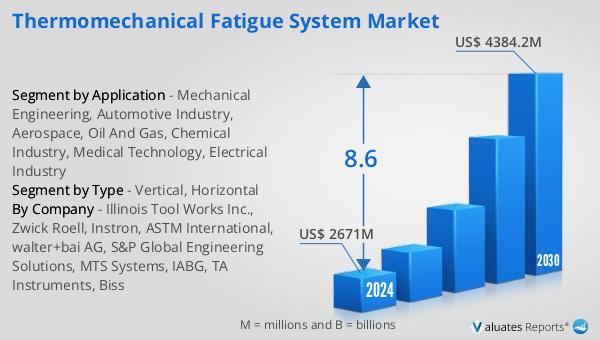

The outlook for the Global Composite Plier Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from a valuation of approximately $2,856 million in 2024 to around $4,690.5 million by 2030. This growth trajectory represents a robust compound annual growth rate (CAGR) of 8.6% during the forecast period. Several factors contribute to this positive outlook, including the increasing demand for high-performance tools across various industries and the continuous advancements in composite material technology. As industries such as automotive, aerospace, and oil and gas continue to evolve, the need for tools that offer superior strength, durability, and resistance to harsh environments becomes more critical. Composite pliers, with their unique blend of materials, are well-positioned to meet these demands, offering a combination of lightweight construction and high performance that traditional metal pliers cannot match. Additionally, the growing emphasis on sustainability and the reduction of carbon footprints in manufacturing processes further supports the adoption of composite materials, which are often more environmentally friendly than their metal counterparts. As a result, the Global Composite Plier Market is poised for substantial growth, driven by the increasing recognition of the benefits offered by composite tools and the ongoing innovation in material science and manufacturing techniques.

| Report Metric | Details |

| Report Name | Composite Plier Market |

| Accounted market size in 2024 | US$ 2856 million |

| Forecasted market size in 2030 | US$ 4690.5 million |

| CAGR | 8.6 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Segment by Region |

|

| By Company | P. F. Freund & Cie. GmbH, Schoenawa Industriebedarf GmbH, Tracht -Odenthal GmbH & CO KG, WILOFA DIAMANT Willi Lohmann GmbH & Co. KG, TOYA S.A., Adjustable Clamp Co., Bass Brothers, The Cincinnati Tool Company, Detroit Machine Screw Works, Handy Manufacturing Co, Holt Mfg Co., Reno Vise Company, The Smith & Egge Mfg. Co., Tarbell, Wetzler |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |