What is Global Light Duty Cantilever Racking Market?

The Global Light Duty Cantilever Racking Market is a specialized segment within the broader storage and shelving industry, focusing on the design and production of cantilever racks that are specifically engineered for lighter loads. These racks are characterized by their unique structure, which includes a central vertical column with horizontal arms extending outwards, allowing for the storage of long, bulky items such as pipes, lumber, or metal bars. Unlike traditional shelving, cantilever racks do not have vertical obstructions at the front, making them ideal for storing items of varying lengths. The market for these racks is driven by the need for efficient storage solutions in industries where space optimization and accessibility are crucial. As businesses continue to seek ways to improve operational efficiency and reduce costs, the demand for light duty cantilever racking systems is expected to grow. These systems are particularly popular in sectors such as manufacturing, retail, and logistics, where they help streamline inventory management and enhance the overall workflow. The market is also influenced by advancements in materials and technology, leading to more durable and versatile racking solutions that can be customized to meet specific industry needs.

Single Sided, Double Sided in the Global Light Duty Cantilever Racking Market:

In the Global Light Duty Cantilever Racking Market, the distinction between single-sided and double-sided racks plays a crucial role in determining their application and efficiency. Single-sided cantilever racks are designed to be placed against a wall, with arms extending only from one side of the vertical column. This configuration is ideal for spaces where wall placement is necessary, or where space is limited. Single-sided racks are often used in smaller workshops or retail environments where maximizing floor space is essential. They provide a streamlined solution for storing items like pipes, lumber, or other elongated materials, allowing for easy access and organization. On the other hand, double-sided cantilever racks offer arms on both sides of the vertical column, effectively doubling the storage capacity without requiring additional floor space. This design is particularly beneficial in larger warehouses or manufacturing facilities where space is abundant, and high-volume storage is required. Double-sided racks are often used in industries that deal with large quantities of materials, such as construction or plumbing, where quick access to inventory is critical. The choice between single-sided and double-sided racks depends largely on the specific needs of the business, including available space, the volume of materials to be stored, and the frequency of access required. Both types of racks offer unique advantages and can be customized with various arm lengths and weight capacities to suit different applications. Additionally, the materials used in constructing these racks, such as steel or aluminum, can impact their durability and load-bearing capabilities. As the market continues to evolve, manufacturers are focusing on developing more versatile and robust racking solutions that can cater to a wide range of industries and storage needs. This includes innovations in design, such as adjustable arms or modular components, which allow for greater flexibility and adaptability in storage configurations. Furthermore, the integration of technology, such as automated retrieval systems or inventory management software, is becoming increasingly common, enhancing the functionality and efficiency of cantilever racking systems. As businesses strive to optimize their storage solutions, the demand for both single-sided and double-sided cantilever racks is expected to grow, driven by the need for efficient, space-saving, and cost-effective storage options.

DIY, Manufacturing, Plumbing and Pipes Industry, Workshops in the Global Light Duty Cantilever Racking Market:

The Global Light Duty Cantilever Racking Market finds extensive usage across various sectors, including DIY, manufacturing, plumbing and pipes industry, and workshops, each benefiting from the unique advantages these racking systems offer. In the DIY sector, light duty cantilever racks are popular for their ability to store a wide range of materials, from lumber and pipes to metal rods and other elongated items. Home improvement enthusiasts and small-scale builders appreciate the accessibility and organization these racks provide, allowing them to efficiently manage their materials and tools. The racks' open design facilitates easy retrieval and inventory management, making them a practical choice for DIY projects where space and organization are key. In the manufacturing industry, light duty cantilever racks play a vital role in optimizing storage and workflow. Manufacturers dealing with long or bulky items, such as automotive parts or metal sheets, rely on these racks to keep their production lines running smoothly. The ability to customize the racks with adjustable arms and varying weight capacities ensures that they can accommodate a diverse range of materials, enhancing operational efficiency and reducing downtime. In the plumbing and pipes industry, the need for efficient storage solutions is paramount, given the nature of the materials involved. Light duty cantilever racks provide an ideal solution for storing pipes, tubes, and other elongated items, allowing for easy access and organization. The racks' design minimizes the risk of damage to the materials, ensuring that they remain in optimal condition for use. Workshops, whether small-scale or industrial, also benefit from the versatility and efficiency of light duty cantilever racking systems. These racks help streamline operations by providing a dedicated space for storing tools, equipment, and materials, reducing clutter and improving workflow. The ability to quickly access and organize items enhances productivity and ensures that workshop operations run smoothly. Overall, the Global Light Duty Cantilever Racking Market offers a range of solutions that cater to the specific needs of various industries, providing efficient, space-saving, and cost-effective storage options that enhance productivity and organization.

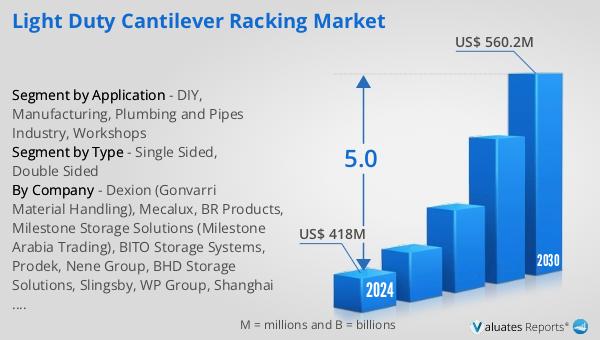

Global Light Duty Cantilever Racking Market Outlook:

The outlook for the Global Light Duty Cantilever Racking Market indicates a promising growth trajectory, with projections suggesting an increase from $418 million in 2024 to $560.2 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.0% during the forecast period. This growth is driven by the increasing demand for efficient storage solutions across various industries, as businesses seek to optimize their operations and reduce costs. The construction machinery sector, in particular, has shown significant growth, with sales in Europe increasing by 24% in 2021. In 2022, the construction machinery revenue in Europe was approximately $22 billion, while the U.S. market recorded sales of about $36 billion. Asian companies have established a dominant presence in the market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This regional distribution highlights the global nature of the market and the diverse range of industries that rely on light duty cantilever racking systems. As businesses continue to prioritize efficiency and cost-effectiveness, the demand for these racking solutions is expected to grow, driven by advancements in materials and technology that enhance their durability and versatility.

| Report Metric | Details |

| Report Name | Light Duty Cantilever Racking Market |

| Accounted market size in 2024 | US$ 418 million |

| Forecasted market size in 2030 | US$ 560.2 million |

| CAGR | 5.0 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Dexion (Gonvarri Material Handling), Mecalux, BR Products, Milestone Storage Solutions (Milestone Arabia Trading), BITO Storage Systems, Prodek, Nene Group, BHD Storage Solutions, Slingsby, WP Group, Shanghai Maxrac Storage Equipment Engineering, Spacerack, Guangzhou HEDA Shelves, Lockheer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |