What is Global Flexographic Printing Ink Concentrates Market?

The Global Flexographic Printing Ink Concentrates Market is a specialized segment within the broader printing industry, focusing on the production and distribution of concentrated inks used in flexographic printing processes. Flexographic printing, often referred to as flexo, is a popular method for printing on a variety of substrates, including paper, plastic, metallic films, and more. This printing technique is widely used due to its versatility, efficiency, and ability to produce high-quality images and text. The concentrates are essentially highly pigmented inks that are diluted before use, allowing for precise control over color intensity and consistency. These concentrates are crucial for industries that require large-scale printing operations, such as packaging, labeling, and publishing. The market for these concentrates is driven by the growing demand for sustainable and efficient printing solutions, as well as the increasing need for high-quality packaging and labeling in various sectors. As industries continue to expand and innovate, the demand for flexographic printing ink concentrates is expected to grow, making it a vital component of the global printing industry.

Water-based, UV Curable, Solvent-based in the Global Flexographic Printing Ink Concentrates Market:

In the realm of Global Flexographic Printing Ink Concentrates Market, three primary types of ink concentrates are prevalent: water-based, UV curable, and solvent-based. Each type has its unique properties and applications, catering to different needs within the printing industry. Water-based ink concentrates are known for their environmental friendliness and safety, as they primarily use water as a solvent, reducing the emission of volatile organic compounds (VOCs). These inks are ideal for printing on porous substrates like paper and cardboard, making them a popular choice in the packaging industry. They offer excellent color vibrancy and are easy to clean, which further enhances their appeal. However, they may not be suitable for non-porous surfaces, as they require longer drying times and may not adhere as well as other types. UV curable ink concentrates, on the other hand, are designed to cure or harden instantly when exposed to ultraviolet light. This rapid curing process allows for faster production speeds and reduces the risk of smudging or smearing. UV curable inks are highly versatile and can be used on a wide range of substrates, including plastics, metals, and glass. They offer excellent adhesion and durability, making them ideal for applications that require high resistance to abrasion and chemicals. Additionally, these inks do not contain solvents, which means they emit little to no VOCs, aligning with the industry's shift towards more sustainable practices. However, the need for specialized UV curing equipment can increase initial setup costs, which may be a consideration for some businesses. Solvent-based ink concentrates are another major category within the flexographic printing ink market. These inks use organic solvents to dissolve the pigments, allowing for quick drying and excellent adhesion to non-porous surfaces. Solvent-based inks are particularly well-suited for printing on materials like plastics and foils, which are commonly used in flexible packaging. They offer vibrant colors and high resistance to environmental factors such as moisture and UV light. However, the use of organic solvents means that these inks can emit VOCs, which may pose environmental and health concerns. As a result, there is a growing trend towards developing low-VOC or VOC-free solvent-based inks to address these issues. Each type of ink concentrate has its advantages and limitations, and the choice often depends on the specific requirements of the printing application. Factors such as substrate type, desired print quality, production speed, and environmental considerations all play a role in determining the most suitable ink concentrate for a given project. As the printing industry continues to evolve, advancements in ink technology are likely to further enhance the performance and sustainability of flexographic printing ink concentrates, ensuring they remain a critical component of modern printing processes.

Packaging Industry, Labels and Stickers, Tissue, Others in the Global Flexographic Printing Ink Concentrates Market:

The Global Flexographic Printing Ink Concentrates Market plays a significant role in various industries, particularly in packaging, labels and stickers, tissue, and other sectors. In the packaging industry, flexographic printing ink concentrates are essential for producing high-quality prints on a wide range of materials, including paper, cardboard, and flexible plastics. The ability to print vibrant colors and intricate designs is crucial for creating attractive packaging that captures consumer attention and communicates brand identity. Flexographic printing is also highly efficient, making it ideal for large-scale production runs commonly required in the packaging sector. The use of ink concentrates allows for precise color matching and consistency, ensuring that packaging meets the stringent quality standards demanded by manufacturers and retailers. In the realm of labels and stickers, flexographic printing ink concentrates are used to produce durable and visually appealing labels that can withstand various environmental conditions. These inks are suitable for printing on different substrates, including paper, film, and foil, providing versatility for label manufacturers. The quick-drying properties of certain ink types, such as UV curable inks, enable high-speed production without compromising print quality. This is particularly important in industries like food and beverage, pharmaceuticals, and consumer goods, where labels must adhere to strict regulatory requirements and maintain their appearance throughout the product's lifecycle. The tissue industry also benefits from the use of flexographic printing ink concentrates, particularly for printing decorative patterns and designs on tissue products such as napkins, paper towels, and toilet paper. The ability to produce high-quality prints on thin and absorbent substrates is a key advantage of flexographic printing. Water-based inks are often preferred in this sector due to their safety and environmental benefits, as they minimize the risk of harmful chemical exposure during production and use. The use of ink concentrates allows manufacturers to achieve vibrant colors and intricate designs, enhancing the aesthetic appeal of tissue products and adding value for consumers. Beyond these specific industries, flexographic printing ink concentrates are used in various other applications, including the production of envelopes, bags, and cartons. The versatility of flexographic printing makes it suitable for a wide range of substrates and print requirements, from simple text and graphics to complex multi-color designs. As industries continue to innovate and seek more sustainable and efficient printing solutions, the demand for high-quality flexographic printing ink concentrates is expected to grow. This growth will be driven by the need for improved print quality, faster production speeds, and environmentally friendly practices, ensuring that flexographic printing remains a vital component of the global printing landscape.

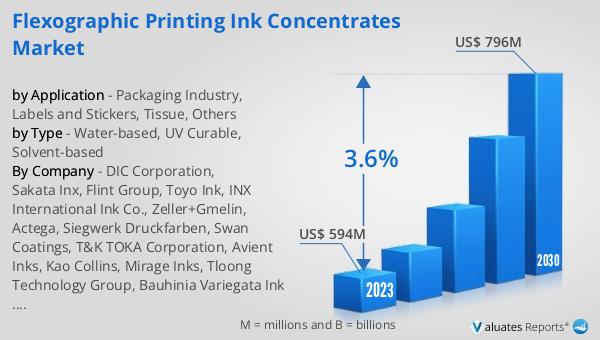

Global Flexographic Printing Ink Concentrates Market Outlook:

In 2023, the global market for Flexographic Printing Ink Concentrates was valued at approximately $594 million. Looking ahead, this market is projected to grow significantly, reaching an estimated value of $796 million by the year 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 3.6% over the forecast period from 2024 to 2030. This steady increase in market value underscores the rising demand for flexographic printing ink concentrates across various industries. The growth can be attributed to several factors, including the expanding packaging industry, the increasing need for high-quality and sustainable printing solutions, and the ongoing advancements in ink technology. As businesses continue to prioritize efficiency and environmental responsibility, the demand for innovative and versatile printing inks is expected to rise. This market outlook highlights the importance of flexographic printing ink concentrates in meeting the evolving needs of the global printing industry, ensuring that they remain a critical component of modern printing processes. The projected growth also indicates opportunities for manufacturers and suppliers to expand their offerings and cater to the diverse requirements of their customers, ultimately contributing to the overall development of the flexographic printing ink concentrates market.

| Report Metric | Details |

| Report Name | Flexographic Printing Ink Concentrates Market |

| Accounted market size in 2023 | US$ 594 million |

| Forecasted market size in 2030 | US$ 796 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DIC Corporation, Sakata Inx, Flint Group, Toyo Ink, INX International Ink Co., Zeller+Gmelin, Actega, Siegwerk Druckfarben, Swan Coatings, T&K TOKA Corporation, Avient Inks, Kao Collins, Mirage Inks, Tloong Technology Group, Bauhinia Variegata Ink & Chemicals (Yip's Chemical) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |