What is Global Thin-film Thickness Monitors Market?

The Global Thin-film Thickness Monitors Market is a specialized segment within the broader field of measurement and instrumentation technology. These monitors are essential tools used to measure the thickness of thin films, which are layers of material ranging from fractions of a nanometer to several micrometers in thickness. Thin films are critical in various industries, including electronics, optics, and materials science, where precise control over film thickness is crucial for product performance and quality. The market for these monitors is driven by the increasing demand for miniaturized electronic devices, advancements in semiconductor technology, and the growing use of thin films in solar panels and display technologies. As industries continue to innovate and push the boundaries of technology, the need for accurate and reliable thin-film thickness measurement tools is expected to grow. These monitors employ various techniques, such as quartz crystal microbalance, optical interferometry, and spectroscopic ellipsometry, each offering different levels of precision and suitability for specific applications. The market is characterized by a mix of established players and emerging companies, all striving to offer advanced solutions that cater to the evolving needs of their customers.

Standard Resolution, High Resolution in the Global Thin-film Thickness Monitors Market:

In the Global Thin-film Thickness Monitors Market, the distinction between standard resolution and high resolution is significant, as it directly impacts the precision and applicability of the measurement tools. Standard resolution monitors are typically used in applications where moderate precision is sufficient. These monitors are often more cost-effective and are suitable for industries where the thin film's thickness does not critically affect the product's performance. For instance, in certain types of coatings or non-critical electronic components, a standard resolution monitor can provide adequate measurement accuracy. These devices usually employ simpler technologies, such as basic optical methods or mechanical stylus profilometry, which are sufficient for less demanding applications. On the other hand, high-resolution thin-film thickness monitors are designed for applications requiring exceptional precision and accuracy. These monitors are essential in industries like semiconductor manufacturing, where even the slightest deviation in film thickness can lead to significant performance issues or product failures. High-resolution monitors often use advanced techniques such as spectroscopic ellipsometry or X-ray reflectometry, which can measure film thickness down to the atomic level. These technologies provide detailed insights into the film's properties, including its refractive index and density, which are crucial for high-tech applications. The choice between standard and high-resolution monitors depends largely on the specific requirements of the application, including the desired level of precision, the nature of the thin film, and the budget constraints. As technology continues to advance, the line between standard and high-resolution monitors is becoming increasingly blurred, with many manufacturers offering hybrid solutions that provide a balance between cost and performance. This trend is driven by the growing demand for versatile measurement tools that can adapt to a wide range of applications, from basic quality control to cutting-edge research and development. The market for thin-film thickness monitors is also influenced by the rapid pace of innovation in related fields, such as materials science and nanotechnology. As new materials and processes are developed, the need for more sophisticated measurement tools becomes apparent, pushing manufacturers to continuously improve their offerings. This dynamic environment presents both challenges and opportunities for companies operating in the thin-film thickness monitors market, as they strive to meet the evolving needs of their customers while staying ahead of the competition. In summary, the distinction between standard and high-resolution thin-film thickness monitors is a key consideration for industries that rely on precise measurement of thin films. While standard resolution monitors offer a cost-effective solution for less demanding applications, high-resolution monitors provide the accuracy and detail required for cutting-edge technologies. As the market continues to evolve, manufacturers are increasingly focusing on developing versatile solutions that can cater to a wide range of needs, ensuring that they remain competitive in this rapidly changing landscape.

High Vacuum System, Ultra-high Vacuum System in the Global Thin-film Thickness Monitors Market:

The usage of Global Thin-film Thickness Monitors Market in high vacuum and ultra-high vacuum systems is crucial for various advanced applications. High vacuum systems, which operate at pressures ranging from 10^-3 to 10^-7 torr, are commonly used in industries such as semiconductor manufacturing, optics, and materials science. In these environments, thin-film thickness monitors play a vital role in ensuring the precise deposition of thin films, which is essential for the performance and reliability of the final product. These monitors help maintain the desired film thickness by providing real-time feedback during the deposition process, allowing for adjustments to be made as needed. This level of control is particularly important in semiconductor manufacturing, where even minor deviations in film thickness can lead to significant performance issues or product failures. Ultra-high vacuum systems, which operate at pressures below 10^-7 torr, are used in more specialized applications, such as surface science research, nanotechnology, and certain types of advanced materials development. In these environments, the need for precise thin-film thickness measurement is even more critical, as the films are often only a few nanometers thick and require exceptional accuracy to ensure their intended properties. Thin-film thickness monitors used in ultra-high vacuum systems typically employ advanced measurement techniques, such as spectroscopic ellipsometry or X-ray reflectometry, which can provide the level of precision needed for these demanding applications. The integration of thin-film thickness monitors into high vacuum and ultra-high vacuum systems also presents certain challenges, such as the need to minimize contamination and ensure compatibility with the vacuum environment. Manufacturers of these monitors must carefully design their products to withstand the harsh conditions of vacuum systems, including extreme temperatures and the presence of reactive gases. This often involves the use of specialized materials and coatings, as well as advanced engineering techniques to ensure the monitors' reliability and longevity. Despite these challenges, the benefits of using thin-film thickness monitors in high vacuum and ultra-high vacuum systems are significant. By providing accurate and reliable measurements, these monitors enable industries to achieve the precise control needed for advanced applications, ultimately leading to improved product performance and quality. As technology continues to advance, the demand for thin-film thickness monitors in high vacuum and ultra-high vacuum systems is expected to grow, driving further innovation and development in this specialized market segment.

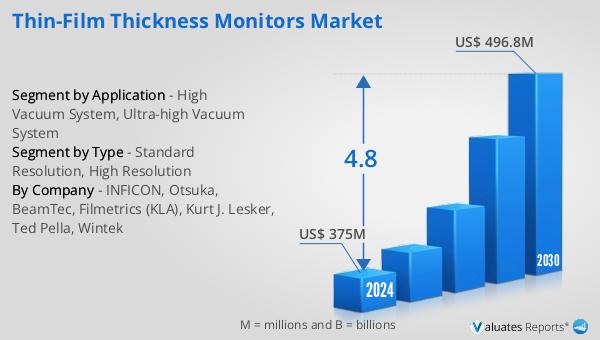

Global Thin-film Thickness Monitors Market Outlook:

The outlook for the Global Thin-film Thickness Monitors Market indicates a promising growth trajectory, with the market expected to expand from $375 million in 2024 to $496.8 million by 2030. This growth is projected to occur at a Compound Annual Growth Rate (CAGR) of 4.8% over the forecast period. This positive outlook is driven by the increasing demand for precise measurement tools across various industries, including electronics, optics, and materials science. The market's growth is further supported by advancements in semiconductor technology and the rising use of thin films in solar panels and display technologies. In parallel, the construction machinery sector has also seen significant growth, particularly in Europe, where sales increased by 24% in 2021. In 2022, the construction machinery revenue in Europe reached approximately $22 billion, while the U.S. market recorded sales of about $36 billion. Asian companies have maintained a dominant position in the market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This data highlights the dynamic nature of the global market landscape, where different regions and industries contribute to the overall growth and development of the thin-film thickness monitors market.

| Report Metric | Details |

| Report Name | Thin-film Thickness Monitors Market |

| Accounted market size in 2024 | US$ 375 million |

| Forecasted market size in 2030 | US$ 496.8 million |

| CAGR | 4.8 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | INFICON, Otsuka, BeamTec, Filmetrics (KLA), Kurt J. Lesker, Ted Pella, Wintek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |