What is Global Pallet Live Storages Market?

The Global Pallet Live Storages Market is a specialized segment within the broader storage and logistics industry, focusing on systems that enhance the efficiency of storing and retrieving palletized goods. These systems are designed to optimize space and improve the flow of goods in warehouses and distribution centers. Pallet live storage systems use gravity to move pallets from the loading end to the picking end, ensuring a smooth and continuous flow of products. This method not only maximizes storage density but also reduces the time and labor required for handling goods. The market for these systems is driven by the increasing demand for efficient storage solutions in various industries, including retail, manufacturing, and logistics. As businesses strive to improve their supply chain operations, the adoption of pallet live storage systems is expected to grow, offering significant benefits in terms of cost savings and operational efficiency. The market is characterized by a range of products, from simple gravity-fed racks to sophisticated automated systems, catering to the diverse needs of businesses worldwide.

FIFO, LIFO in the Global Pallet Live Storages Market:

In the context of the Global Pallet Live Storages Market, FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two critical inventory management strategies that dictate how goods are stored and retrieved. FIFO is a method where the oldest inventory is used or sold first, ensuring that products are rotated efficiently and reducing the risk of obsolescence or spoilage. This approach is particularly beneficial for industries dealing with perishable goods, such as food and pharmaceuticals, where maintaining product freshness is crucial. In a pallet live storage system, FIFO is naturally facilitated by the gravity-fed design, where pallets are loaded from one end and retrieved from the other, ensuring that the first pallet loaded is the first to be picked. This system not only optimizes space but also enhances inventory turnover, leading to improved cash flow and reduced holding costs. On the other hand, LIFO is a method where the most recently added inventory is used or sold first. This approach can be advantageous in industries where the cost of goods is rising, as it allows businesses to match current sales with the most recent, and often higher, costs. However, LIFO can lead to challenges in managing older inventory, which may become obsolete or deteriorate over time. In a pallet live storage system, implementing LIFO requires careful planning and management to ensure that older inventory is not neglected. While LIFO can offer tax advantages in certain regions, it may not be suitable for all businesses, particularly those dealing with perishable goods. The choice between FIFO and LIFO in the Global Pallet Live Storages Market depends on various factors, including the nature of the products, market conditions, and regulatory requirements. Businesses must carefully evaluate their inventory management needs and choose the strategy that aligns with their operational goals and financial objectives. As the market continues to evolve, the integration of advanced technologies, such as automation and data analytics, is expected to further enhance the efficiency and effectiveness of both FIFO and LIFO systems, providing businesses with greater flexibility and control over their inventory management processes.

Warehouses, Stores, Production Facilities, Workshops, Others in the Global Pallet Live Storages Market:

The Global Pallet Live Storages Market finds extensive application across various sectors, including warehouses, stores, production facilities, workshops, and other areas. In warehouses, pallet live storage systems are used to maximize storage density and improve the efficiency of goods handling. By utilizing gravity-fed racks, these systems enable quick and easy access to inventory, reducing the time and labor required for picking and replenishment. This is particularly beneficial in high-volume distribution centers where speed and accuracy are critical. In retail stores, pallet live storage systems help manage inventory effectively, ensuring that products are readily available for customers while minimizing the risk of overstocking or stockouts. These systems allow for efficient product rotation, which is essential for maintaining the freshness and quality of goods, especially in sectors like grocery and pharmaceuticals. In production facilities, pallet live storage systems support just-in-time manufacturing processes by ensuring that raw materials and components are readily accessible for production lines. This reduces downtime and enhances productivity, leading to cost savings and improved operational efficiency. In workshops, these systems facilitate the organization and storage of tools and materials, enabling workers to access the items they need quickly and efficiently. This not only improves workflow but also enhances safety by reducing clutter and minimizing the risk of accidents. Other areas where pallet live storage systems are used include cold storage facilities, where maintaining the integrity of temperature-sensitive goods is crucial, and e-commerce fulfillment centers, where rapid order processing and delivery are essential to meet customer expectations. Overall, the versatility and efficiency of pallet live storage systems make them an invaluable asset in a wide range of applications, helping businesses optimize their storage operations and improve their bottom line.

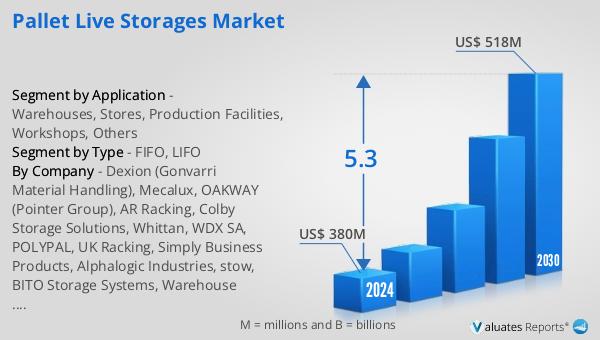

Global Pallet Live Storages Market Outlook:

The outlook for the Global Pallet Live Storages Market is promising, with projections indicating growth from $380 million in 2024 to $518 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period. This growth is driven by the increasing demand for efficient storage solutions across various industries. According to research from our Construction Machinery center, the sales of construction machinery in Europe saw a significant increase of 24% in 2021. In 2022, the construction machinery revenue in Europe was approximately $22 billion, while the U.S. market recorded sales of about $36 billion in construction machinery. Asian companies hold a dominant position in the market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This data highlights the growing importance of efficient storage solutions in supporting the expanding construction industry and other sectors. As businesses continue to seek ways to optimize their supply chain operations, the adoption of pallet live storage systems is expected to rise, offering significant benefits in terms of cost savings and operational efficiency. The market is characterized by a range of products, from simple gravity-fed racks to sophisticated automated systems, catering to the diverse needs of businesses worldwide. As the market evolves, the integration of advanced technologies, such as automation and data analytics, is expected to further enhance the efficiency and effectiveness of pallet live storage systems, providing businesses with greater flexibility and control over their inventory management processes.

| Report Metric | Details |

| Report Name | Pallet Live Storages Market |

| Accounted market size in 2024 | US$ 380 in million |

| Forecasted market size in 2030 | US$ 518 million |

| CAGR | 5.3 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Dexion (Gonvarri Material Handling), Mecalux, OAKWAY (Pointer Group), AR Racking, Colby Storage Solutions, Whittan, WDX SA, POLYPAL, UK Racking, Simply Business Products, Alphalogic Industries, stow, BITO Storage Systems, Warehouse Systems, Avanta, Prodek, Noega Systems, Brännehylte Lagersystem AB |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |