What is Gear Testing Systems - Global Market?

Gear testing systems are specialized tools used to evaluate the quality and performance of gears, which are crucial components in many mechanical systems. These systems are designed to measure various parameters such as gear noise, vibration, and accuracy, ensuring that the gears meet specific standards and function efficiently. The global market for gear testing systems is driven by the increasing demand for high-quality gears in industries like automotive, aerospace, and manufacturing. As technology advances, the need for precise and reliable gear testing becomes more critical, pushing manufacturers to invest in advanced testing systems. These systems not only help in maintaining the quality of gears but also play a significant role in reducing production costs by identifying defects early in the manufacturing process. With the growing emphasis on quality and efficiency, the gear testing systems market is expected to expand, offering numerous opportunities for innovation and development in testing technologies. The market's growth is also supported by the increasing adoption of automation and digitalization in manufacturing processes, which require sophisticated testing solutions to ensure the seamless operation of automated systems. Overall, gear testing systems are essential for maintaining the integrity and performance of gears across various applications, making them a vital component of the global industrial landscape.

Error Measurement and Testing, On-board Measurement and Testing, Laser Measurement and Testing in the Gear Testing Systems - Global Market:

Error measurement and testing in gear testing systems involve assessing the precision and accuracy of gears by identifying deviations from the desired specifications. This process is crucial for ensuring that gears function correctly and efficiently in their respective applications. Error measurement typically involves the use of advanced sensors and software to detect and quantify errors such as misalignment, surface defects, and dimensional inaccuracies. These errors can significantly impact the performance and lifespan of gears, leading to increased maintenance costs and potential system failures. On-board measurement and testing refer to the integration of testing systems directly into the machinery or equipment where the gears are used. This approach allows for real-time monitoring and assessment of gear performance, enabling immediate detection and correction of issues. On-board testing systems are particularly beneficial in applications where continuous operation is critical, as they help prevent unexpected downtime and ensure optimal performance. Laser measurement and testing are advanced techniques used in gear testing systems to achieve high precision and accuracy. Laser-based systems utilize laser beams to measure the dimensions and surface characteristics of gears with exceptional accuracy. This method is highly effective in detecting minute defects and deviations that may not be visible through traditional testing methods. Laser measurement is particularly useful in industries where precision is paramount, such as aerospace and high-performance automotive applications. The integration of these advanced testing techniques into gear testing systems enhances their capability to deliver reliable and accurate results, ensuring the production of high-quality gears that meet stringent industry standards. As the demand for precision and efficiency continues to rise, the adoption of error measurement, on-board testing, and laser measurement technologies in gear testing systems is expected to grow, driving further advancements in the field.

Automotive, Aerospace, Machinery, Others in the Gear Testing Systems - Global Market:

Gear testing systems play a vital role in various industries, including automotive, aerospace, machinery, and others, by ensuring the quality and performance of gears used in these sectors. In the automotive industry, gears are essential components in transmissions, differentials, and other critical systems. Gear testing systems help automotive manufacturers maintain high standards of quality and reliability by detecting defects and ensuring that gears meet the required specifications. This is crucial for enhancing vehicle performance, fuel efficiency, and safety. In the aerospace industry, the demand for precision and reliability is even more pronounced. Gears used in aircraft engines and other critical systems must adhere to stringent standards to ensure safety and performance. Gear testing systems in aerospace applications focus on detecting even the smallest defects and deviations to prevent potential failures that could have catastrophic consequences. The machinery industry also relies heavily on gear testing systems to ensure the smooth operation of various equipment and machinery. High-quality gears are essential for the efficient functioning of industrial machines, and testing systems help manufacturers identify and rectify issues before they lead to costly breakdowns. Other industries, such as wind energy and robotics, also benefit from gear testing systems. In wind turbines, for example, gears are subjected to high loads and harsh environmental conditions, making regular testing essential for maintaining performance and preventing failures. Similarly, in robotics, precision gears are crucial for accurate and reliable operation, and testing systems help ensure that these components meet the necessary standards. Overall, gear testing systems are indispensable tools across various industries, helping to maintain the quality, performance, and reliability of gears in diverse applications.

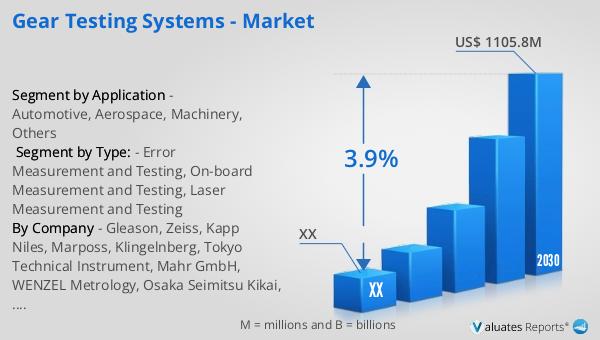

Gear Testing Systems - Global Market Outlook:

The global market for gear testing systems was valued at approximately $868 million in 2023 and is projected to grow to around $1,105.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality gears across various industries, as well as advancements in testing technologies. According to research from the "Construction Machinery" sector, sales of construction machinery in Europe saw a significant increase of 24% in 2021. In 2022, the revenue from construction machinery in Europe was estimated to be about $22 billion, while the United States market recorded sales of approximately $36 billion in construction machinery. These figures highlight the growing demand for machinery and equipment that rely on high-quality gears, further emphasizing the importance of gear testing systems in ensuring the performance and reliability of these components. As industries continue to prioritize quality and efficiency, the gear testing systems market is expected to witness steady growth, offering opportunities for innovation and development in testing technologies. The increasing adoption of automation and digitalization in manufacturing processes also contributes to the demand for advanced gear testing solutions, as these systems are essential for maintaining the integrity and performance of automated systems. Overall, the gear testing systems market is poised for growth, driven by the need for precision and reliability in gear manufacturing and the expanding demand for high-quality gears across various industries.

| Report Metric | Details |

| Report Name | Gear Testing Systems - Market |

| Forecasted market size in 2030 | US$ 1105.8 million |

| CAGR | 3.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Gleason, Zeiss, Kapp Niles, Marposs, Klingelnberg, Tokyo Technical Instrument, Mahr GmbH, WENZEL Metrology, Osaka Seimitsu Kikai, United Tool Supply |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |