What is Global Heavy Duty Vertical Balers Market?

The Global Heavy Duty Vertical Balers Market refers to the industry focused on the production and distribution of machines designed to compress and compact waste materials into dense bales. These balers are particularly useful for managing large volumes of recyclable materials such as cardboard, plastics, and metals, making them essential for businesses and organizations that generate significant waste. Heavy duty vertical balers are characterized by their robust construction and ability to handle high volumes of material, making them suitable for industrial and commercial applications. They operate by using a vertical pressing mechanism to compress materials, which are then bound into bales for easy handling, storage, and transportation. The market for these machines is driven by the increasing need for efficient waste management solutions, as well as the growing emphasis on recycling and sustainability. As businesses and institutions strive to reduce their environmental impact, the demand for heavy duty vertical balers is expected to rise, offering opportunities for manufacturers and suppliers in this sector. The market is also influenced by technological advancements that enhance the efficiency and functionality of these machines, making them more appealing to a broader range of users.

Compaction Force 10 Tonnes, Compaction Force 20 Tonnes, Compaction Force 50 Tonnes, Others in the Global Heavy Duty Vertical Balers Market:

In the Global Heavy Duty Vertical Balers Market, compaction force is a critical factor that determines the efficiency and effectiveness of the baling process. Compaction force refers to the pressure applied by the baler to compress materials into dense bales. Different models of vertical balers offer varying levels of compaction force, typically measured in tonnes, to accommodate different types of materials and volumes. A compaction force of 10 tonnes is generally suitable for smaller operations or materials that do not require significant pressure to compact, such as lightweight plastics or paper. These balers are often used in settings where space is limited, and the volume of waste is relatively low. On the other hand, a compaction force of 20 tonnes is more appropriate for medium-sized operations or materials that are slightly more challenging to compress, such as cardboard or mixed recyclables. These balers provide a balance between power and efficiency, making them a popular choice for businesses that generate moderate amounts of waste. For larger operations or materials that require substantial pressure to compact, such as metals or dense plastics, a compaction force of 50 tonnes or more is necessary. These heavy-duty balers are designed to handle high volumes of waste and are often used in industrial settings where efficiency and productivity are paramount. In addition to these standard compaction forces, there are also balers available with customizable pressure settings to meet specific needs. These versatile machines can be adjusted to provide the optimal compaction force for a wide range of materials, offering flexibility and adaptability for users. The choice of compaction force is influenced by several factors, including the type and volume of material to be baled, the available space for the baler, and the budget constraints of the user. As the demand for efficient waste management solutions continues to grow, manufacturers are focusing on developing balers with enhanced compaction capabilities to meet the diverse needs of their customers. This includes innovations in hydraulic systems and control mechanisms that allow for precise adjustments to the compaction force, ensuring optimal performance and efficiency. Additionally, advancements in materials and construction techniques are enabling the production of balers that are both powerful and durable, capable of withstanding the rigors of heavy-duty use. As a result, the Global Heavy Duty Vertical Balers Market is expected to see continued growth and development, driven by the increasing need for effective waste management solutions and the ongoing emphasis on sustainability and environmental responsibility.

Super Markets, Department Stores, Universities, Military Bases, Others in the Global Heavy Duty Vertical Balers Market:

The usage of Global Heavy Duty Vertical Balers Market extends across various sectors, including supermarkets, department stores, universities, military bases, and others, each benefiting from the efficient waste management solutions these machines provide. In supermarkets, heavy duty vertical balers play a crucial role in managing the large volumes of cardboard and plastic waste generated from packaging materials. By compacting these materials into dense bales, supermarkets can significantly reduce the space required for waste storage, streamline their recycling processes, and ultimately lower their waste disposal costs. Similarly, department stores, which also deal with substantial amounts of packaging waste, benefit from the use of vertical balers to maintain a clean and organized environment while promoting sustainable practices. In universities, the implementation of heavy duty vertical balers supports campus-wide recycling initiatives by efficiently managing the diverse range of recyclable materials generated by students and staff. These balers help universities reduce their environmental footprint and align with sustainability goals, while also providing educational opportunities for students to learn about waste management and recycling processes. Military bases, which often operate as self-contained communities, generate significant amounts of waste from various activities. The use of heavy duty vertical balers on military bases aids in the efficient management of waste materials, contributing to the overall cleanliness and sustainability of the base operations. Additionally, these balers help military bases comply with environmental regulations and reduce the logistical challenges associated with waste disposal. Beyond these specific sectors, heavy duty vertical balers are also utilized in a wide range of other settings, including manufacturing facilities, distribution centers, and hospitality venues. In each of these environments, the primary benefit of using vertical balers is the ability to efficiently manage waste materials, reduce disposal costs, and support sustainability efforts. As businesses and organizations across various industries continue to prioritize environmental responsibility, the demand for heavy duty vertical balers is expected to grow, driving further innovation and development in this market.

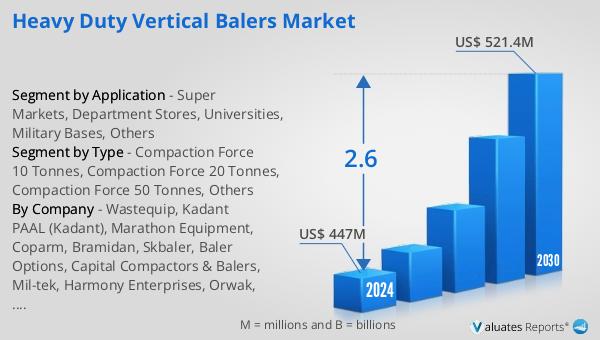

Global Heavy Duty Vertical Balers Market Outlook:

The global Heavy Duty Vertical Balers market is anticipated to expand from $447 million in 2024 to $521.4 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 2.6% throughout the forecast period. Insights from our Construction Machinery research center indicate a notable increase in the sales of construction machinery in Europe, with a 24% rise in 2021. In 2022, the revenue from construction machinery in Europe reached approximately $22 billion, while the U.S. market recorded sales of about $36 billion in the same year. Asian companies hold a dominant position in the market, accounting for 50% of the revenue, followed by Europe and North America, which contribute 26% and 23%, respectively. This growth trajectory underscores the increasing demand for efficient waste management solutions and the pivotal role of heavy duty vertical balers in addressing this need. As industries and organizations worldwide continue to emphasize sustainability and environmental responsibility, the market for these machines is poised for further expansion. The ongoing advancements in technology and the development of more efficient and versatile balers are expected to drive this growth, offering new opportunities for manufacturers and suppliers in the sector.

| Report Metric | Details |

| Report Name | Heavy Duty Vertical Balers Market |

| Accounted market size in 2024 | US$ 447 in million |

| Forecasted market size in 2030 | US$ 521.4 million |

| CAGR | 2.6 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Wastequip, Kadant PAAL (Kadant), Marathon Equipment, Coparm, Bramidan, Skbaler, Baler Options, Capital Compactors & Balers, Mil-tek, Harmony Enterprises, Orwak, Riverside Waste Machinery, Global Trash Solutions, Moovmor Engineering, PTR Baler and Compactor, Harris, Mardon, Mark-Costello, Zibo United Tech Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |