What is Global Mobile Cantilever Racking Market?

The Global Mobile Cantilever Racking Market is an essential segment within the storage and logistics industry, providing a versatile and efficient solution for storing long and bulky items. These racking systems are designed with arms that extend from a central column, allowing for easy access and organization of materials such as lumber, pipes, and metal bars. The mobile aspect of these racks means they can be moved or adjusted to accommodate different storage needs, making them highly adaptable to various warehouse configurations. This flexibility is particularly beneficial in industries where inventory sizes and types frequently change. The market for mobile cantilever racking is driven by the increasing demand for efficient storage solutions that maximize space utilization while ensuring easy access to stored goods. As industries continue to grow and evolve, the need for innovative storage solutions like mobile cantilever racking is expected to rise, making it a crucial component in modern logistics and supply chain management.

Semi Electric, Fully Electric in the Global Mobile Cantilever Racking Market:

In the Global Mobile Cantilever Racking Market, the distinction between semi-electric and fully electric systems is significant, as each offers unique advantages and caters to different operational needs. Semi-electric mobile cantilever racking systems combine manual and electric components, providing a balance between cost-effectiveness and operational efficiency. These systems typically require manual intervention for certain functions, such as positioning or locking the racks, while electric motors assist in moving the racks along tracks. This hybrid approach allows businesses to benefit from some level of automation without the higher costs associated with fully electric systems. Semi-electric systems are particularly suitable for smaller operations or those with budget constraints, where full automation may not be necessary. On the other hand, fully electric mobile cantilever racking systems offer a higher degree of automation, with electric motors handling all aspects of rack movement and positioning. These systems are ideal for larger warehouses or facilities with high throughput requirements, where speed and efficiency are paramount. Fully electric systems can significantly reduce the time and labor required for material handling, leading to increased productivity and reduced operational costs. The choice between semi-electric and fully electric systems often depends on factors such as the size of the facility, the volume of goods handled, and budget considerations. As technology advances, the capabilities of both semi-electric and fully electric systems continue to improve, offering businesses more options to optimize their storage and logistics operations. The integration of advanced technologies, such as IoT and automation, is further enhancing the functionality and efficiency of these systems, making them an integral part of modern warehousing and logistics strategies. As businesses strive to improve their supply chain efficiency and reduce costs, the demand for both semi-electric and fully electric mobile cantilever racking systems is expected to grow, driving innovation and development in this market segment.

Warehouses, Stores, Production Facilities, Workshops, Others in the Global Mobile Cantilever Racking Market:

The Global Mobile Cantilever Racking Market finds extensive usage across various sectors, including warehouses, stores, production facilities, workshops, and other areas, each benefiting from the unique advantages these systems offer. In warehouses, mobile cantilever racking systems are invaluable for optimizing space and improving inventory management. They allow for the efficient storage of long and bulky items, which are often challenging to accommodate with traditional shelving systems. The mobility of these racks enables warehouses to adapt to changing inventory needs, ensuring that space is used effectively and that items are easily accessible. In retail stores, mobile cantilever racking systems provide a practical solution for displaying and storing products such as carpets, textiles, and other long items. The ability to move and adjust the racks allows stores to create dynamic displays that can be easily reconfigured to highlight different products or accommodate seasonal changes in inventory. In production facilities, these racking systems support efficient material handling and storage, ensuring that raw materials and finished products are organized and accessible. This is particularly important in industries such as manufacturing and construction, where the timely availability of materials is crucial to maintaining production schedules. Workshops also benefit from mobile cantilever racking systems, as they provide a convenient way to store tools, equipment, and materials. The flexibility of these systems allows workshops to optimize their workspace, ensuring that tools and materials are readily available when needed. Additionally, mobile cantilever racking systems are used in various other settings, such as distribution centers and logistics hubs, where efficient storage and retrieval of goods are essential to maintaining smooth operations. The adaptability and efficiency of these systems make them a valuable asset in any setting where space optimization and easy access to stored items are priorities.

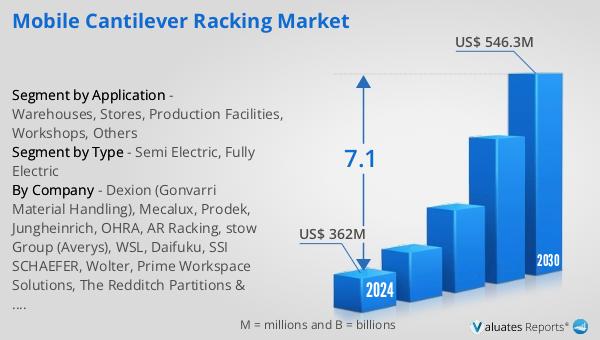

Global Mobile Cantilever Racking Market Outlook:

The outlook for the Global Mobile Cantilever Racking Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from $362 million in 2024 to $546.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.1% during this period. This growth is driven by the increasing demand for efficient storage solutions across various industries, as well as advancements in technology that enhance the functionality and efficiency of mobile cantilever racking systems. The construction machinery sector, in particular, has seen notable growth, with sales in Europe increasing by 24% in 2021. In 2022, construction machinery revenue in Europe reached approximately $22 billion, while the U.S. market recorded sales of around $36 billion. Asian companies have a significant presence in this market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This distribution highlights the global nature of the market and the diverse range of industries that rely on mobile cantilever racking systems to optimize their storage and logistics operations. As businesses continue to seek ways to improve efficiency and reduce costs, the demand for innovative storage solutions like mobile cantilever racking is expected to grow, driving further development and innovation in this market.

| Report Metric | Details |

| Report Name | Mobile Cantilever Racking Market |

| Accounted market size in 2024 | US$ 362 million |

| Forecasted market size in 2030 | US$ 546.3 million |

| CAGR | 7.1 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Dexion (Gonvarri Material Handling), Mecalux, Prodek, Jungheinrich, OHRA, AR Racking, stow Group (Averys), WSL, Daifuku, SSI SCHAEFER, Wolter, Prime Workspace Solutions, The Redditch Partitions & Storage, BITO Storage Systems, Space Productiv, Konstant, POLYPAL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |