What is Industrial Cycloid Gears - Global Market?

Industrial cycloid gears are a specialized type of gear system used in various industrial applications. Unlike traditional gears, cycloid gears use a unique mechanism that involves a rolling motion, which reduces friction and increases efficiency. This design allows for smoother and quieter operation, making them ideal for precision tasks. The global market for industrial cycloid gears is expanding due to their increasing demand in sectors like robotics, manufacturing, and mechanical transmission systems. These gears are known for their durability and ability to handle high torque loads, which makes them suitable for heavy-duty applications. As industries continue to automate and seek more efficient machinery, the demand for cycloid gears is expected to grow. This growth is driven by the need for reliable and efficient gear systems that can enhance the performance of industrial equipment. The market is also influenced by technological advancements that improve the design and functionality of cycloid gears, making them more adaptable to various industrial needs. Overall, the industrial cycloid gears market is poised for steady growth as industries prioritize efficiency and precision in their operations.

Single Stage Gears, Double-Stage Gears in the Industrial Cycloid Gears - Global Market:

Single-stage and double-stage gears are integral components of industrial cycloid gear systems, each serving distinct purposes based on the requirements of the application. Single-stage gears are designed for applications where a single reduction in speed is sufficient. They are simpler in design and are often used in applications where space is limited or where the gear system needs to be compact. Single-stage gears are typically used in applications that require moderate torque and speed reduction, such as conveyor systems and small machinery. Their simplicity makes them cost-effective and easy to maintain, which is why they are popular in industries that require reliable yet straightforward gear systems. On the other hand, double-stage gears are used in applications that require a greater reduction in speed and an increase in torque. These gears involve two stages of gear reduction, which allows for more precise control over speed and torque. Double-stage gears are commonly used in heavy machinery and equipment that require high torque, such as cranes, hoists, and large industrial machines. The additional stage of gear reduction provides the necessary power and control needed for these demanding applications. The choice between single-stage and double-stage gears depends on several factors, including the specific requirements of the application, the available space, and the desired level of efficiency. In the global market for industrial cycloid gears, both single-stage and double-stage gears play crucial roles. Manufacturers are continually innovating to improve the performance and efficiency of these gears, making them more adaptable to the evolving needs of various industries. As industries continue to advance and require more sophisticated machinery, the demand for both single-stage and double-stage gears is expected to increase. This demand is driven by the need for gear systems that can provide precise control, high efficiency, and reliability in various industrial applications. The global market for industrial cycloid gears is characterized by a diverse range of applications, each requiring specific gear configurations to meet their unique needs. As a result, manufacturers are focusing on developing versatile gear systems that can cater to a wide range of industrial applications. This focus on versatility and adaptability is expected to drive the growth of the industrial cycloid gears market in the coming years.

Mechanical Transmission, Industrial Robots, Others in the Industrial Cycloid Gears - Global Market:

Industrial cycloid gears are widely used in various applications, including mechanical transmission, industrial robots, and other sectors. In mechanical transmission, cycloid gears are valued for their ability to provide smooth and efficient power transfer. They are commonly used in machinery that requires precise control over speed and torque, such as conveyor systems, pumps, and compressors. The unique design of cycloid gears allows for minimal friction and wear, which enhances the longevity and reliability of mechanical transmission systems. This makes them an ideal choice for industries that require durable and efficient gear systems. In the field of industrial robots, cycloid gears play a crucial role in ensuring precise and accurate movements. The high torque capacity and smooth operation of cycloid gears make them suitable for robotic applications that require precise positioning and control. They are often used in robotic arms and other automated systems where precision and reliability are paramount. The use of cycloid gears in industrial robots is expected to increase as industries continue to adopt automation and robotics to improve efficiency and productivity. Beyond mechanical transmission and industrial robots, cycloid gears are also used in various other applications. They are commonly found in packaging machinery, food processing equipment, and other industrial machines that require reliable and efficient gear systems. The versatility of cycloid gears makes them suitable for a wide range of applications, and their ability to handle high torque loads makes them ideal for heavy-duty machinery. As industries continue to evolve and seek more efficient and reliable gear systems, the demand for cycloid gears is expected to grow. This growth is driven by the need for gear systems that can enhance the performance and efficiency of industrial equipment. Overall, the use of industrial cycloid gears in mechanical transmission, industrial robots, and other applications is expected to increase as industries prioritize efficiency, precision, and reliability in their operations.

Industrial Cycloid Gears - Global Market Outlook:

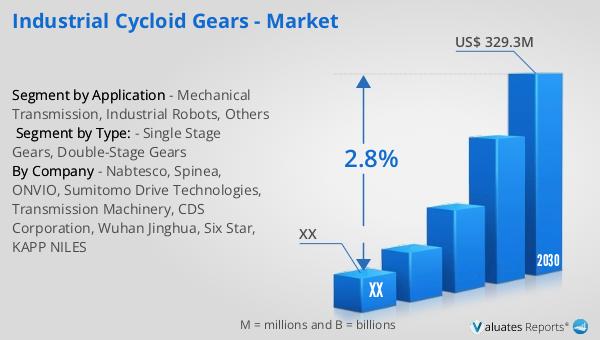

The global market for industrial cycloid gears was valued at approximately $267 million in 2023. It is projected to grow to a revised size of $329.3 million by 2030, with a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for cycloid gears in various industrial applications. The broader global gears market is also experiencing growth, with an expected market size of $262,720 million by 2029, growing at a CAGR of 3.8% from 2023 to 2029. This growth is driven by the need for efficient and reliable gear systems in industries such as manufacturing, robotics, and mechanical transmission. The demand for cycloid gears is particularly strong in sectors that require high precision and efficiency, such as industrial robotics and automation. As industries continue to advance and seek more sophisticated machinery, the demand for cycloid gears is expected to increase. This demand is further fueled by technological advancements that improve the design and functionality of cycloid gears, making them more adaptable to various industrial needs. Overall, the global market for industrial cycloid gears is poised for steady growth as industries prioritize efficiency and precision in their operations.

| Report Metric | Details |

| Report Name | Industrial Cycloid Gears - Market |

| Forecasted market size in 2030 | US$ 329.3 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nabtesco, Spinea, ONVIO, Sumitomo Drive Technologies, Transmission Machinery, CDS Corporation, Wuhan Jinghua, Six Star, KAPP NILES |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |