What is Non-Expanded Polymer Coated Fabrics - Global Market?

Non-expanded polymer coated fabrics are a specialized segment within the broader textile industry, characterized by their unique coating process that does not involve expanding the polymer. These fabrics are created by applying a thin layer of polymer onto a textile substrate, which enhances the fabric's properties without altering its inherent structure. This coating process imparts various beneficial attributes to the fabric, such as increased durability, resistance to water and chemicals, and enhanced aesthetic appeal. The global market for non-expanded polymer coated fabrics is driven by their versatile applications across multiple industries, including automotive, marine, construction, and furniture. These fabrics are particularly valued for their ability to withstand harsh environmental conditions, making them ideal for outdoor and industrial applications. As industries continue to seek materials that offer both functionality and longevity, the demand for non-expanded polymer coated fabrics is expected to grow. The market is also influenced by technological advancements in coating techniques and the development of new polymer formulations that offer improved performance characteristics. Overall, non-expanded polymer coated fabrics represent a dynamic and evolving market with significant potential for growth and innovation.

Polyurethane, PVC (Polyvinyl Chloride), Silicone in the Non-Expanded Polymer Coated Fabrics - Global Market:

Polyurethane, PVC (Polyvinyl Chloride), and silicone are three primary types of polymers used in the production of non-expanded polymer coated fabrics, each offering distinct properties and advantages. Polyurethane coated fabrics are renowned for their flexibility, durability, and resistance to abrasion, making them a popular choice in applications where these attributes are crucial. They are often used in the automotive and furniture industries, where the need for materials that can withstand wear and tear is paramount. Polyurethane coatings also provide a soft, leather-like feel, which enhances the aesthetic appeal of the fabric. Additionally, they offer excellent resistance to oil and grease, making them suitable for industrial applications. PVC coated fabrics, on the other hand, are known for their excellent waterproofing capabilities and resistance to chemicals. This makes them ideal for use in environments where exposure to moisture and harsh chemicals is a concern, such as in marine and construction applications. PVC coatings are also highly durable and can withstand prolonged exposure to sunlight without degrading, making them suitable for outdoor use. However, PVC is less flexible than polyurethane, which can limit its use in applications where flexibility is a key requirement. Silicone coated fabrics offer a unique set of properties that make them suitable for specialized applications. Silicone coatings provide excellent thermal stability, allowing the fabric to withstand extreme temperatures without losing its integrity. This makes silicone coated fabrics ideal for use in environments where temperature fluctuations are common, such as in the aerospace and automotive industries. Additionally, silicone coatings offer excellent resistance to UV radiation and weathering, making them suitable for outdoor applications. They also provide a non-stick surface, which can be beneficial in applications where ease of cleaning is important. Despite their advantages, silicone coated fabrics are generally more expensive than their polyurethane and PVC counterparts, which can limit their use to high-end applications where performance is prioritized over cost. Overall, the choice of polymer coating depends on the specific requirements of the application, with each type offering unique benefits that cater to different industry needs.

Furniture Industry (Upholstery, etc.), Automobiles, Marine Vehicle Transportation, Construction Industry, Other in the Non-Expanded Polymer Coated Fabrics - Global Market:

Non-expanded polymer coated fabrics find extensive usage across various industries due to their enhanced properties and versatility. In the furniture industry, these fabrics are commonly used for upholstery, providing a durable and aesthetically pleasing surface that can withstand daily wear and tear. The coatings enhance the fabric's resistance to stains and spills, making them ideal for use in households with children or pets. Additionally, the wide range of colors and textures available allows for creative design possibilities, enabling manufacturers to cater to diverse consumer preferences. In the automotive sector, non-expanded polymer coated fabrics are used in the production of seat covers, dashboards, and interior linings. Their durability and resistance to abrasion make them suitable for the demanding conditions of vehicle interiors, while their ability to mimic the appearance of leather provides a cost-effective alternative to traditional materials. In marine vehicle transportation, these fabrics are used for boat covers, seating, and other components exposed to harsh marine environments. The coatings provide excellent resistance to water, salt, and UV radiation, ensuring the longevity of the fabric in challenging conditions. In the construction industry, non-expanded polymer coated fabrics are used for roofing membranes, awnings, and other architectural applications. Their ability to withstand extreme weather conditions and provide waterproofing makes them ideal for use in construction projects. Additionally, these fabrics are used in other applications such as protective clothing, luggage, and industrial covers, where their enhanced properties provide added value. Overall, the versatility and durability of non-expanded polymer coated fabrics make them a valuable material across a wide range of industries.

Non-Expanded Polymer Coated Fabrics - Global Market Outlook:

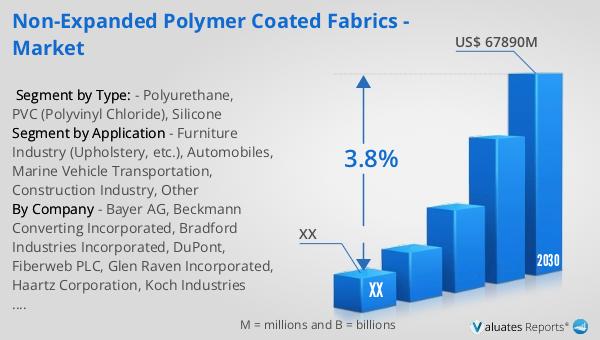

The market outlook for non-expanded polymer coated fabrics indicates a strong presence of polyurethane coated fabrics, which account for nearly half of the market share. This dominance is attributed to the versatility and desirable properties of polyurethane, which make it suitable for a wide range of applications. Within the broader usage of polyurethane in various forms, the textile fabric segment alone captures about 5% of the market. In 2023, the global market for non-expanded polymer coated fabrics was valued at approximately US$ 52,630 million. Looking ahead, it is projected to reach a revised size of US$ 67,890 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience growth, although specific figures for this region were not provided. This growth is driven by the increasing demand for durable and versatile materials across various industries, as well as advancements in polymer coating technologies. As industries continue to prioritize materials that offer both functionality and longevity, the market for non-expanded polymer coated fabrics is poised for continued expansion.

| Report Metric | Details |

| Report Name | Non-Expanded Polymer Coated Fabrics - Market |

| Forecasted market size in 2030 | US$ 67890 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bayer AG, Beckmann Converting Incorporated, Bradford Industries Incorporated, DuPont, Fiberweb PLC, Glen Raven Incorporated, Haartz Corporation, Koch Industries Incorporated, OMNOVA Solutions, Saint-Gobain, Takata Corporation, Uniroyal Engineered Products LLC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |