What is TB Vaccines - Global Market?

TB vaccines are a crucial component of the global healthcare landscape, aimed at combating tuberculosis, a highly infectious disease caused by the Mycobacterium tuberculosis bacteria. The global market for TB vaccines encompasses the development, production, and distribution of vaccines designed to prevent tuberculosis infection. This market is driven by the high prevalence of TB, particularly in developing countries, and the ongoing efforts to eradicate the disease worldwide. TB vaccines are primarily used to protect individuals, especially those in high-risk groups, from contracting the disease. The market includes various types of vaccines, such as the Bacillus Calmette-Guérin (BCG) vaccine, which is the most widely used TB vaccine globally. The demand for TB vaccines is influenced by factors such as government initiatives, international health organization campaigns, and the increasing awareness of TB prevention. Additionally, advancements in vaccine technology and research are contributing to the development of more effective and safer TB vaccines, further propelling the market growth. The TB vaccines market is a vital part of the broader pharmaceutical industry, playing a significant role in public health efforts to reduce the incidence and spread of tuberculosis worldwide.

Immunotherapeutic Vaccines, Booster Vaccines, Others in the TB Vaccines - Global Market:

Immunotherapeutic vaccines, booster vaccines, and other types of TB vaccines represent distinct segments within the global TB vaccines market, each serving unique purposes in the fight against tuberculosis. Immunotherapeutic vaccines are designed to enhance the body's immune response against TB, providing a therapeutic benefit to individuals who are already infected with the disease. These vaccines work by stimulating the immune system to recognize and attack the TB bacteria more effectively, potentially reducing the severity of the disease and preventing its progression. Immunotherapeutic vaccines are particularly important for individuals with latent TB infections, as they can help prevent the activation of the disease. Booster vaccines, on the other hand, are administered to individuals who have previously received a primary TB vaccination, such as the BCG vaccine, to enhance or prolong the immune protection against TB. Booster vaccines are crucial in maintaining immunity, especially in regions with high TB prevalence, where the risk of infection remains significant over time. These vaccines are often given to healthcare workers, travelers, and individuals in close contact with TB patients to ensure continued protection. The "others" category in the TB vaccines market includes various experimental and next-generation vaccines that are currently under development or in clinical trials. These vaccines aim to provide broader and more effective protection against TB, addressing the limitations of existing vaccines like BCG. Researchers are exploring novel approaches, such as recombinant vaccines and subunit vaccines, to improve the efficacy and safety of TB vaccines. The development of these new vaccines is driven by the need to combat drug-resistant strains of TB and to provide better protection for vulnerable populations, including children and immunocompromised individuals. The global TB vaccines market is characterized by ongoing research and innovation, with numerous pharmaceutical companies, research institutions, and government agencies collaborating to develop and distribute effective vaccines. The market is also influenced by regulatory frameworks, funding from international health organizations, and partnerships between public and private sectors. As the understanding of TB pathogenesis and immune responses improves, the development of more targeted and effective vaccines is expected to continue, contributing to the global efforts to eliminate tuberculosis as a public health threat.

Hospitals, Private Clinics, Research Institutes in the TB Vaccines - Global Market:

The usage of TB vaccines in hospitals, private clinics, and research institutes plays a critical role in the global effort to control and eventually eradicate tuberculosis. In hospitals, TB vaccines are primarily used as a preventive measure for newborns and children, particularly in regions with high TB prevalence. Hospitals serve as key vaccination centers, where healthcare professionals administer the BCG vaccine to infants shortly after birth to provide early protection against TB. Additionally, hospitals are involved in the management and treatment of TB cases, where immunotherapeutic vaccines may be used as part of the treatment regimen for patients with active or latent TB infections. Hospitals also play a role in monitoring and reporting TB cases, contributing to the surveillance and control of the disease. In private clinics, TB vaccines are often administered to individuals who may not have access to public healthcare facilities or who prefer private healthcare services. Private clinics provide an alternative vaccination option for individuals seeking TB prevention, including travelers, healthcare workers, and individuals in high-risk occupations. These clinics may offer booster vaccines to enhance immunity for those who have previously received the BCG vaccine. Private clinics also play a role in educating patients about TB prevention and the importance of vaccination, contributing to increased awareness and uptake of TB vaccines. Research institutes are at the forefront of TB vaccine development, conducting studies and clinical trials to evaluate the safety and efficacy of new and existing vaccines. These institutes collaborate with pharmaceutical companies, government agencies, and international health organizations to advance TB vaccine research and development. Research institutes are involved in exploring novel vaccine candidates, understanding the immune mechanisms involved in TB protection, and identifying potential biomarkers for vaccine efficacy. The work conducted in research institutes is crucial for the development of next-generation TB vaccines that can address the challenges posed by drug-resistant TB strains and provide better protection for vulnerable populations. Overall, the usage of TB vaccines in hospitals, private clinics, and research institutes is integral to the global strategy for TB prevention and control, ensuring that vaccines are accessible, effective, and continuously improved to meet the evolving needs of public health.

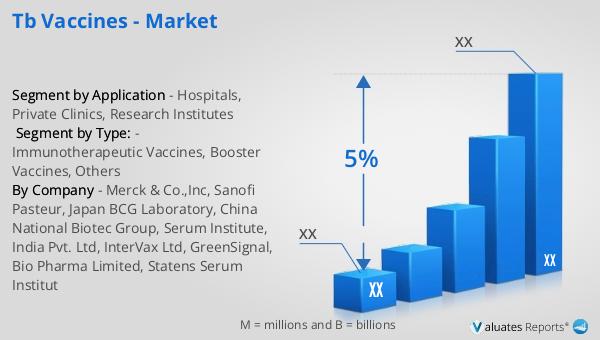

TB Vaccines - Global Market Outlook:

The outlook for the TB vaccines market can be contextualized within the broader pharmaceutical industry landscape. As of 2022, the global pharmaceutical market is valued at approximately 1,475 billion USD, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth trajectory reflects the increasing demand for pharmaceutical products, driven by factors such as population growth, aging demographics, and the rising prevalence of chronic diseases. In comparison, the chemical drug market, a significant segment of the pharmaceutical industry, has shown a steady increase from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market underscores the ongoing demand for traditional pharmaceutical products, including vaccines, which are essential for disease prevention and management. The TB vaccines market, as part of the broader pharmaceutical landscape, benefits from these industry trends, with increasing investments in research and development, advancements in vaccine technology, and growing awareness of the importance of vaccination in public health. The market outlook for TB vaccines is shaped by these factors, highlighting the critical role of vaccines in addressing global health challenges and the continued efforts to improve vaccine accessibility and efficacy.

| Report Metric | Details |

| Report Name | TB Vaccines - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Merck & Co.,Inc, Sanofi Pasteur, Japan BCG Laboratory, China National Biotec Group, Serum Institute, India Pvt. Ltd, InterVax Ltd, GreenSignal, Bio Pharma Limited, Statens Serum Institut |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |