What is Global Precision Hydraulic Seamless Steel Pipe Market?

The Global Precision Hydraulic Seamless Steel Pipe Market is a specialized segment within the broader steel pipe industry. These pipes are known for their high precision, durability, and seamless construction, which makes them ideal for hydraulic systems that require high pressure and reliability. The seamless nature of these pipes means they are manufactured without any welded joints, which enhances their strength and reduces the risk of leaks or failures under pressure. These pipes are used in various industries, including automotive, aerospace, and petrochemical, where precision and reliability are paramount. The market for these pipes is driven by the increasing demand for high-performance hydraulic systems, advancements in manufacturing technologies, and the need for efficient and reliable piping solutions in critical applications. The global market is characterized by a mix of established players and new entrants, all striving to innovate and meet the evolving needs of their customers.

Round, Special-Shaped in the Global Precision Hydraulic Seamless Steel Pipe Market:

Round and special-shaped precision hydraulic seamless steel pipes are two primary types within the global market, each serving distinct applications and industries. Round pipes are the most common and are typically used in applications where uniformity and strength are crucial. These pipes are manufactured to precise dimensions, ensuring consistent performance in hydraulic systems. They are often used in automotive manufacturing, where they play a critical role in the hydraulic systems of vehicles, including braking and steering mechanisms. The round shape allows for even distribution of pressure, which is essential for the safe and efficient operation of hydraulic systems. On the other hand, special-shaped pipes are designed for specific applications that require unique geometries. These pipes can be oval, square, or any other shape that meets the specific needs of an application. Special-shaped pipes are often used in aerospace and petrochemical industries, where space constraints and unique design requirements necessitate custom solutions. The manufacturing process for these pipes is more complex, involving advanced techniques to ensure precision and reliability. Both round and special-shaped pipes are made from high-quality steel, which undergoes rigorous testing to meet industry standards. The choice between round and special-shaped pipes depends on the specific requirements of the application, including factors such as pressure, temperature, and environmental conditions. In summary, the global precision hydraulic seamless steel pipe market offers a range of products to meet the diverse needs of various industries, with round and special-shaped pipes each providing unique benefits and applications.

Automobile Manufacturing, Aerospace, Petrochemical in the Global Precision Hydraulic Seamless Steel Pipe Market:

The usage of global precision hydraulic seamless steel pipes spans several critical industries, including automobile manufacturing, aerospace, and petrochemical. In automobile manufacturing, these pipes are integral to the hydraulic systems that control various functions such as braking, steering, and suspension. The high precision and seamless construction of these pipes ensure that they can withstand the high pressures and stresses encountered in automotive applications. This reliability is crucial for the safety and performance of vehicles, making these pipes a preferred choice for automotive manufacturers. In the aerospace industry, precision hydraulic seamless steel pipes are used in the hydraulic systems of aircraft, where they play a vital role in controlling flight surfaces, landing gear, and other critical components. The aerospace industry demands the highest levels of precision and reliability, as any failure in the hydraulic system can have catastrophic consequences. The seamless construction of these pipes eliminates the risk of leaks and ensures consistent performance under extreme conditions, such as high altitudes and varying temperatures. In the petrochemical industry, these pipes are used to transport various fluids and gases under high pressure. The seamless design of the pipes ensures that they can handle the corrosive and high-pressure environments typical of petrochemical applications. This durability and reliability make them an essential component in the infrastructure of petrochemical plants, where any failure can lead to significant safety hazards and financial losses. Overall, the global precision hydraulic seamless steel pipe market provides critical solutions for these industries, ensuring the safe and efficient operation of hydraulic systems in some of the most demanding applications.

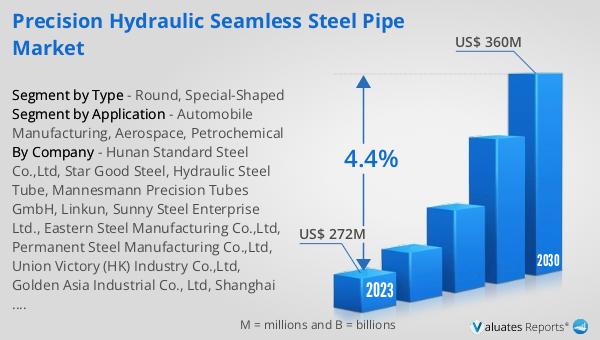

Global Precision Hydraulic Seamless Steel Pipe Market Outlook:

The global Precision Hydraulic Seamless Steel Pipe market was valued at US$ 272 million in 2023 and is anticipated to reach US$ 360 million by 2030, witnessing a CAGR of 4.4% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for precision hydraulic seamless steel pipes across various industries. The projected growth rate of 4.4% indicates a robust market expansion driven by the need for high-performance hydraulic systems in automotive, aerospace, and petrochemical sectors. The increase in market value from US$ 272 million to US$ 360 million underscores the importance of these pipes in critical applications where precision, durability, and reliability are paramount. As industries continue to evolve and demand more efficient and reliable hydraulic solutions, the market for precision hydraulic seamless steel pipes is expected to grow steadily. This growth is supported by advancements in manufacturing technologies, which enable the production of high-quality pipes that meet stringent industry standards. The market outlook reflects the ongoing efforts of manufacturers to innovate and provide solutions that cater to the specific needs of their customers, ensuring the continued relevance and demand for precision hydraulic seamless steel pipes in the global market.

| Report Metric | Details |

| Report Name | Precision Hydraulic Seamless Steel Pipe Market |

| Accounted market size in 2023 | US$ 272 million |

| Forecasted market size in 2030 | US$ 360 million |

| CAGR | 4.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hunan Standard Steel Co.,Ltd, Star Good Steel, Hydraulic Steel Tube, Mannesmann Precision Tubes GmbH, Linkun, Sunny Steel Enterprise Ltd., Eastern Steel Manufacturing Co.,Ltd, Permanent Steel Manufacturing Co.,Ltd, Union Victory (HK) Industry Co.,Ltd, Golden Asia Industrial Co., Ltd, Shanghai Metal, RFS Hydraulics, Zhejiang Etune Special Steel Tube Co., Ltd, Sanjack Petro, KARAY METALS, INC, Xuzhou Global Precision Steel Tube Co.,Ltd, Multinox Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |