What is Global Aluminum Plates Market?

The Global Aluminum Plates Market is a significant segment within the broader aluminum industry, characterized by its diverse applications and robust demand across various sectors. Aluminum plates are flat, thick sheets of aluminum that are used in a wide range of industries due to their lightweight, corrosion resistance, and excellent strength-to-weight ratio. These plates are manufactured in different grades and thicknesses to cater to specific industrial needs. The market for aluminum plates is driven by the increasing demand from industries such as aerospace, automotive, construction, and marine, where the material's properties are highly valued. The global market is also influenced by technological advancements in manufacturing processes, which enhance the quality and performance of aluminum plates. Additionally, the growing emphasis on sustainability and recycling in the aluminum industry contributes to the market's expansion, as aluminum is a highly recyclable material. The market is competitive, with numerous players striving to innovate and offer high-quality products to meet the evolving demands of end-users. Overall, the Global Aluminum Plates Market is poised for growth, supported by its critical role in various industrial applications and the ongoing trends towards lightweight and sustainable materials.

2XXX, 5XXX, 6XXX, 7XXX, 8XXX, Others in the Global Aluminum Plates Market:

The Global Aluminum Plates Market is segmented into various series based on the alloy composition, each offering distinct properties and applications. The 2XXX series, primarily alloyed with copper, is known for its high strength and excellent machinability, making it ideal for aerospace applications where structural integrity is paramount. These plates are often used in aircraft components and other high-stress environments. The 5XXX series, alloyed with magnesium, is renowned for its exceptional corrosion resistance and weldability. This makes it a preferred choice for marine applications, automotive parts, and pressure vessels. Its ability to withstand harsh environments without compromising on strength is a significant advantage. The 6XXX series, which includes silicon and magnesium, offers a good balance of strength, corrosion resistance, and formability. These plates are versatile and are commonly used in construction, transportation, and architectural applications. The 7XXX series, primarily alloyed with zinc, is known for its superior strength and is extensively used in aerospace and defense sectors. These plates are crucial in manufacturing aircraft structures and other high-performance applications where strength is critical. The 8XXX series, which includes other elements like lithium, is designed for specific applications requiring unique properties such as improved strength-to-weight ratios. These plates are often used in advanced aerospace applications and other specialized industries. Beyond these series, there are other aluminum plate variants that cater to niche markets and specific industrial needs. These include plates with enhanced thermal conductivity, improved surface finish, or tailored mechanical properties to meet the demands of particular applications. The diversity in alloy compositions and properties allows the Global Aluminum Plates Market to cater to a wide array of industries, each with its unique requirements and challenges. The ongoing research and development in alloy technology continue to expand the possibilities for aluminum plates, driving innovation and growth in the market.

Aerospace & Defense, Automobile, Rail and Ship, Mechanical Engineering or Moulding, Others in the Global Aluminum Plates Market:

The Global Aluminum Plates Market finds extensive usage across various industries, each leveraging the unique properties of aluminum to enhance performance and efficiency. In the aerospace and defense sector, aluminum plates are indispensable due to their lightweight nature and high strength. They are used in the construction of aircraft frames, fuselage panels, and other critical components where weight reduction is crucial for fuel efficiency and performance. The corrosion resistance of aluminum also ensures longevity and reliability in harsh environments. In the automotive industry, aluminum plates contribute to the production of lightweight vehicles, which are essential for improving fuel efficiency and reducing emissions. They are used in manufacturing body panels, engine components, and structural parts, offering a balance of strength and weight savings. The rail and shipbuilding industries also benefit from aluminum plates, as they provide durability and resistance to corrosion, essential for long-term performance in marine and rail environments. Aluminum's ability to withstand harsh weather conditions and its ease of fabrication make it a preferred material for hulls, decks, and railcar bodies. In mechanical engineering and molding, aluminum plates are used for creating molds and dies due to their excellent machinability and thermal conductivity. They allow for precise and efficient production processes, enhancing the quality and consistency of manufactured products. Other industries, such as construction and electronics, also utilize aluminum plates for their versatility and performance characteristics. In construction, they are used for roofing, cladding, and structural components, while in electronics, they serve as heat sinks and enclosures. The adaptability of aluminum plates to various applications underscores their importance in modern industrial processes, driving demand and innovation in the Global Aluminum Plates Market.

Global Aluminum Plates Market Outlook:

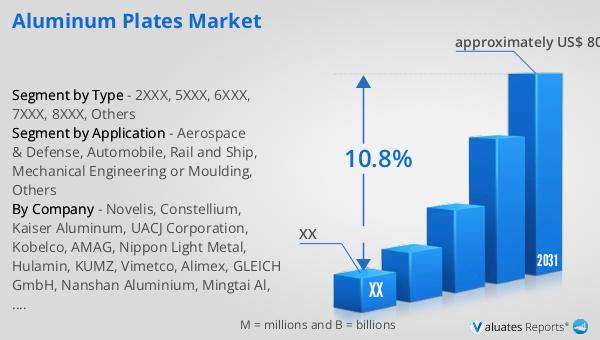

In 2024, the global market size of aluminum plates was valued at approximately US$ 39,680 million, with projections indicating a significant growth trajectory. By 2031, the market is expected to reach around US$ 80,760 million, reflecting a robust compound annual growth rate (CAGR) of 10.8% during the forecast period from 2025 to 2031. This growth is driven by the increasing demand across various industries, including aerospace, automotive, and construction, where aluminum plates are valued for their lightweight, strength, and corrosion resistance. The market is dominated by the top five manufacturers, who collectively hold about 75% of the market share, indicating a competitive landscape with significant influence from leading players. Europe emerges as the largest regional market, accounting for approximately 30% of the global share, followed closely by North America with a 27% share. This regional dominance is attributed to the strong industrial base and technological advancements in these areas. In terms of product segmentation, the 5XXX series stands out as the largest segment, capturing about 30% of the market share. This series is particularly favored for its excellent corrosion resistance and weldability, making it suitable for marine and automotive applications. The market outlook reflects a dynamic and evolving industry, poised for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Aluminum Plates Market |

| Forecasted market size in 2031 | approximately US$ 80760 million |

| CAGR | 10.8% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Novelis, Constellium, Kaiser Aluminum, UACJ Corporation, Kobelco, AMAG, Nippon Light Metal, Hulamin, KUMZ, Vimetco, Alimex, GLEICH GmbH, Nanshan Aluminium, Mingtai Al, Chalco, ALG Aluminium, Jingmei Aluminium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |