What is Global Construction Industry Core Drill Market?

The global construction industry core drill market is a specialized segment within the broader construction equipment industry, focusing on tools used for drilling precise holes in hard materials like concrete, stone, and asphalt. Core drills are essential for various construction activities, including installing plumbing, electrical systems, and HVAC systems, as well as for structural testing and analysis. The market is driven by the increasing demand for infrastructure development, urbanization, and the need for renovation and maintenance of existing structures. Core drills come in various sizes and configurations, including handheld and rig-mounted models, to accommodate different project requirements. The market is characterized by technological advancements that enhance the efficiency, safety, and precision of drilling operations. Manufacturers are focusing on developing more durable and efficient core drills to meet the growing demands of the construction industry. The market is also influenced by regional construction trends, regulatory standards, and the availability of skilled labor. As construction projects become more complex and demanding, the need for reliable and efficient core drilling solutions continues to grow, making the global construction industry core drill market a vital component of the construction sector.

Wet Drill Bits, Dry Drill Bits in the Global Construction Industry Core Drill Market:

Wet drill bits and dry drill bits are two primary types of core drill bits used in the global construction industry, each serving distinct purposes based on the nature of the drilling task and the material being drilled. Wet drill bits are designed to be used with water or other cooling fluids, which help to reduce heat generated during the drilling process, minimize dust, and prolong the life of the drill bit. These bits are particularly effective for drilling into hard materials like reinforced concrete, granite, and marble, where the cooling effect of the water prevents overheating and ensures a smoother, more precise cut. The use of water also helps to flush out debris from the drilling site, maintaining a clean working environment and reducing the risk of damage to the drill bit. Wet drilling is often preferred in situations where precision and cleanliness are paramount, such as in the installation of plumbing and electrical systems, or when working in sensitive environments where dust control is critical. On the other hand, dry drill bits are designed for use without water, making them ideal for situations where water is not readily available or where its use could cause damage or inconvenience. Dry drilling is commonly used for materials like brick, block, and softer concrete, where the risk of overheating is lower, and the need for dust control is less critical. These bits are often equipped with special features, such as vacuum attachments or dust extraction systems, to manage dust and debris during the drilling process. Dry drill bits are particularly useful in renovation projects or in areas where water use is restricted, such as in historical buildings or in regions with water scarcity. The choice between wet and dry drill bits depends largely on the specific requirements of the project, including the material being drilled, the working environment, and the availability of resources. Both types of drill bits have their advantages and limitations, and selecting the right one is crucial for achieving optimal results in core drilling operations. As the global construction industry continues to evolve, the demand for both wet and dry drill bits is expected to grow, driven by the need for efficient, reliable, and versatile drilling solutions. Manufacturers are continually innovating to improve the performance and durability of these drill bits, incorporating advanced materials and design features to meet the diverse needs of the construction sector. Whether for large-scale infrastructure projects or smaller renovation tasks, wet and dry drill bits play a critical role in ensuring the success and efficiency of core drilling operations.

Electricians, Plumbers, Other in the Global Construction Industry Core Drill Market:

The global construction industry core drill market finds extensive usage across various trades, including electricians, plumbers, and other construction professionals, each benefiting from the precision and efficiency that core drills provide. Electricians, for instance, rely heavily on core drills to create precise openings for electrical conduits, junction boxes, and other components within walls, floors, and ceilings. The ability to drill clean, accurate holes is crucial for maintaining the integrity of electrical systems and ensuring safety and compliance with building codes. Core drills enable electricians to work efficiently, reducing the time and effort required to install complex electrical networks in both residential and commercial buildings. Plumbers also benefit significantly from the use of core drills, as they are essential for installing pipes and fixtures in various construction settings. Whether it's for water supply, drainage, or gas lines, core drills allow plumbers to create the necessary openings in concrete, brick, or other materials, ensuring a secure and leak-free installation. The precision offered by core drills is particularly important in plumbing, where even minor inaccuracies can lead to significant issues, such as leaks or misalignments. In addition to electricians and plumbers, other construction professionals, such as HVAC technicians, carpenters, and general contractors, also utilize core drills for a variety of tasks. HVAC technicians, for example, use core drills to create openings for ductwork and ventilation systems, ensuring efficient airflow and optimal system performance. Carpenters may use core drills to install structural elements or fixtures, while general contractors rely on them for a wide range of construction and renovation tasks. The versatility and efficiency of core drills make them indispensable tools in the construction industry, enabling professionals to complete their work with precision and confidence. As construction projects become more complex and demanding, the need for reliable and efficient core drilling solutions continues to grow, making the global construction industry core drill market a vital component of the construction sector.

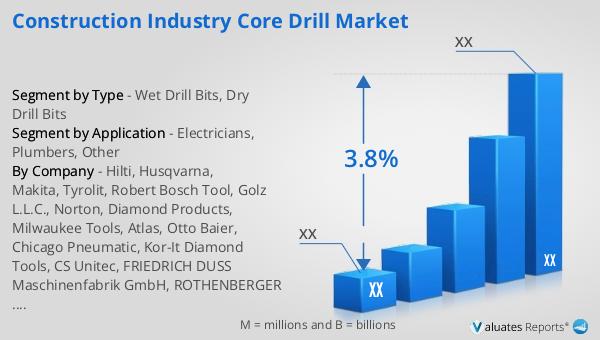

Global Construction Industry Core Drill Market Outlook:

In 2024, the global market size of the construction industry core drill was valued at approximately US$ 1163 million. This market is projected to expand significantly, reaching an estimated value of around US$ 1504 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2025 to 2031. The market is characterized by the presence of several key players, with the top five manufacturers collectively holding about 40% of the market share. This concentration of market power among leading manufacturers highlights the competitive nature of the industry, where innovation, quality, and customer service are critical factors for success. The projected growth of the market is driven by several factors, including the increasing demand for infrastructure development, urbanization, and the need for renovation and maintenance of existing structures. As construction projects become more complex and demanding, the need for reliable and efficient core drilling solutions continues to grow, making the global construction industry core drill market a vital component of the construction sector. The market is also influenced by regional construction trends, regulatory standards, and the availability of skilled labor. As the industry continues to evolve, manufacturers are focusing on developing more durable and efficient core drills to meet the growing demands of the construction industry.

| Report Metric | Details |

| Report Name | Construction Industry Core Drill Market |

| CAGR | 3.8% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hilti, Husqvarna, Makita, Tyrolit, Robert Bosch Tool, Golz L.L.C., Norton, Diamond Products, Milwaukee Tools, Atlas, Otto Baier, Chicago Pneumatic, Kor-It Diamond Tools, CS Unitec, FRIEDRICH DUSS Maschinenfabrik GmbH, ROTHENBERGER Werkzeuge GmbH, BOSUN, Zhongshan Jielian Mechatronics Co., ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |