What is Global Industrial Decorative Coating Market?

The Global Industrial Decorative Coating Market refers to the industry that produces coatings used to enhance the appearance and durability of industrial structures and products. These coatings are applied to a variety of surfaces, including metals, plastics, and wood, to protect them from corrosion, wear, and environmental damage while also providing an aesthetically pleasing finish. The market encompasses a wide range of products, including paints, varnishes, and other coatings, which are used in various industries such as automotive, aerospace, construction, and manufacturing. The demand for industrial decorative coatings is driven by factors such as the growth of the construction and automotive industries, increasing urbanization, and the need for protective coatings that can withstand harsh environmental conditions. Technological advancements in coating formulations and application techniques are also contributing to the growth of this market. The global industrial decorative coating market is characterized by a high level of competition, with numerous players offering a diverse range of products to meet the specific needs of different industries.

Epoxy Paint, Polyurethane Paint, Acrylic Paint, Alkyd Paint in the Global Industrial Decorative Coating Market:

Epoxy paint, polyurethane paint, acrylic paint, and alkyd paint are some of the key types of coatings used in the global industrial decorative coating market. Epoxy paint is known for its excellent adhesion, chemical resistance, and durability, making it ideal for use in harsh industrial environments. It is commonly used on metal surfaces, such as pipelines, storage tanks, and machinery, to protect them from corrosion and wear. Polyurethane paint, on the other hand, is valued for its high gloss finish, flexibility, and resistance to abrasion and UV radiation. This type of paint is often used in the automotive and aerospace industries, as well as for coating floors and other surfaces that require a durable and attractive finish. Acrylic paint is a versatile and fast-drying coating that offers good weather resistance and color retention. It is widely used in the construction industry for both interior and exterior applications, including walls, roofs, and facades. Acrylic paint is also popular in the automotive industry for its ability to provide a smooth and glossy finish. Alkyd paint, which is based on alkyd resins, is known for its excellent adhesion, durability, and ease of application. It is commonly used in the construction and manufacturing industries for coating metal and wood surfaces. Alkyd paint is also used in the production of decorative items, such as furniture and fixtures, due to its ability to provide a high-quality finish. Each of these types of paints has its own unique properties and advantages, making them suitable for different applications and industries. The choice of paint depends on factors such as the type of surface to be coated, the environmental conditions, and the desired finish.

Residential Building, Commercial Building, Others in the Global Industrial Decorative Coating Market:

The global industrial decorative coating market finds extensive usage in various areas, including residential buildings, commercial buildings, and other sectors. In residential buildings, these coatings are used to enhance the aesthetic appeal and protect the surfaces of homes and apartments. They are applied to walls, ceilings, floors, and exterior surfaces to provide a durable and attractive finish that can withstand everyday wear and tear. The use of high-quality coatings in residential buildings helps to improve the overall appearance and value of the property, while also providing protection against moisture, UV radiation, and other environmental factors. In commercial buildings, industrial decorative coatings are used to create a professional and appealing environment for businesses and their customers. These coatings are applied to a wide range of surfaces, including walls, floors, ceilings, and exterior facades, to provide a durable and attractive finish that can withstand heavy foot traffic and other forms of wear and tear. The use of industrial decorative coatings in commercial buildings helps to create a positive impression on clients and customers, while also providing protection against damage and reducing maintenance costs. In addition to residential and commercial buildings, industrial decorative coatings are also used in other sectors, such as the automotive, aerospace, and manufacturing industries. In the automotive industry, these coatings are used to provide a high-quality finish to vehicles, while also protecting them from corrosion, UV radiation, and other environmental factors. In the aerospace industry, industrial decorative coatings are used to protect aircraft from harsh environmental conditions and improve their appearance. In the manufacturing industry, these coatings are used to protect machinery and equipment from wear and tear, while also providing a durable and attractive finish. Overall, the global industrial decorative coating market plays a crucial role in enhancing the appearance and durability of various structures and products across different industries.

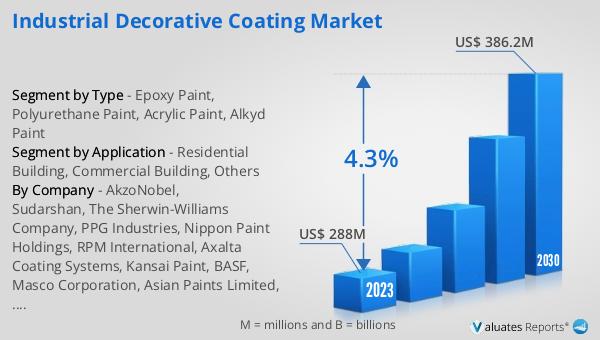

Global Industrial Decorative Coating Market Outlook:

The global industrial decorative coating market was valued at US$ 288 million in 2023 and is anticipated to reach US$ 386.2 million by 2030, witnessing a CAGR of 4.3% during the forecast period from 2024 to 2030. This growth can be attributed to several factors, including the increasing demand for protective and aesthetically pleasing coatings in various industries, such as construction, automotive, and aerospace. The rising urbanization and industrialization in emerging economies are also driving the demand for industrial decorative coatings, as more buildings and infrastructure projects require high-quality coatings to enhance their appearance and durability. Additionally, technological advancements in coating formulations and application techniques are contributing to the growth of the market, as they enable the development of more efficient and effective coatings that meet the specific needs of different industries. The competitive landscape of the global industrial decorative coating market is characterized by the presence of numerous players offering a diverse range of products, which further drives innovation and growth in the market. Overall, the global industrial decorative coating market is expected to continue its growth trajectory in the coming years, driven by the increasing demand for high-quality coatings across various industries.

| Report Metric | Details |

| Report Name | Industrial Decorative Coating Market |

| Accounted market size in 2023 | US$ 288 million |

| Forecasted market size in 2030 | US$ 386.2 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel, Sudarshan, The Sherwin-Williams Company, PPG Industries, Nippon Paint Holdings, RPM International, Axalta Coating Systems, Kansai Paint, BASF, Masco Corporation, Asian Paints Limited, Schlenk AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |