What is Global Aseptic Filling Machine Market?

The Global Aseptic Filling Machine Market is a crucial segment within the packaging industry, focusing on the technology and machinery used to fill sterile products into containers in a way that maintains their sterility. This market is driven by the increasing demand for safe and long-lasting food and beverage products, pharmaceuticals, and other consumables that require aseptic processing to ensure safety and extend shelf life. Aseptic filling machines are designed to prevent contamination by maintaining a sterile environment during the filling process, which is essential for products that cannot be heat-sterilized after packaging. The market encompasses a variety of machines that cater to different product types, including liquids, powders, and semi-solids, and is characterized by technological advancements aimed at improving efficiency, reducing waste, and enhancing product safety. As consumer awareness about health and safety continues to grow, the demand for aseptic filling solutions is expected to rise, making this market a vital component of the global packaging industry.

Fully-automatic, Semi-automatic in the Global Aseptic Filling Machine Market:

In the Global Aseptic Filling Machine Market, machines are generally categorized into fully-automatic and semi-automatic systems, each offering distinct advantages and catering to different operational needs. Fully-automatic aseptic filling machines are designed for high-volume production environments where speed and precision are paramount. These machines are equipped with advanced technology that allows them to perform the entire filling process without human intervention, from sterilizing containers to sealing them after filling. This automation not only enhances efficiency but also minimizes the risk of contamination, making fully-automatic machines ideal for industries such as pharmaceuticals and large-scale food and beverage production. They are particularly beneficial in settings where consistent output and stringent hygiene standards are required, as they can operate continuously with minimal downtime. On the other hand, semi-automatic aseptic filling machines offer a balance between automation and manual control, making them suitable for smaller operations or those that require a degree of flexibility. These machines typically require human intervention at certain stages of the filling process, such as loading containers or initiating the filling cycle. While they may not match the speed of fully-automatic systems, semi-automatic machines provide greater control over the filling process, allowing operators to make adjustments as needed. This can be advantageous for businesses that produce a variety of products in smaller batches, as it enables them to switch between different product types or container sizes with relative ease. Additionally, semi-automatic machines often have a lower initial cost compared to their fully-automatic counterparts, making them an attractive option for startups or companies with budget constraints. Despite their differences, both fully-automatic and semi-automatic aseptic filling machines play a crucial role in ensuring product safety and quality. They are designed to maintain a sterile environment throughout the filling process, which is essential for preventing contamination and preserving the integrity of the product. As such, the choice between fully-automatic and semi-automatic systems largely depends on the specific needs and priorities of the business, including production volume, budget, and the level of control desired over the filling process. In conclusion, the Global Aseptic Filling Machine Market offers a range of solutions to meet the diverse needs of the packaging industry, with fully-automatic and semi-automatic machines each providing unique benefits that cater to different operational requirements.

Liquid, Powder in the Global Aseptic Filling Machine Market:

The Global Aseptic Filling Machine Market serves a wide range of applications, particularly in the filling of liquids and powders, each with its own set of challenges and requirements. In the realm of liquid filling, aseptic machines are indispensable for industries such as dairy, beverages, and pharmaceuticals, where maintaining product sterility is crucial. These machines are designed to handle various types of liquids, from water and juices to more viscous substances like sauces and creams. The aseptic filling process for liquids involves several critical steps, including sterilizing the containers and the filling environment, as well as ensuring that the liquid itself is free from contaminants. This is achieved through advanced filtration and sterilization techniques, which help to extend the shelf life of the product without the need for preservatives. Aseptic filling machines for liquids are often equipped with precision dosing systems that ensure accurate filling volumes, reducing waste and ensuring consistency across batches. In addition to liquids, the aseptic filling of powders is another significant application within this market. Powdered products, such as infant formula, nutritional supplements, and certain pharmaceuticals, require careful handling to prevent contamination and ensure product integrity. Aseptic filling machines for powders are designed to handle the unique challenges associated with powder filling, such as dust generation and the need for precise dosing. These machines often incorporate specialized features, such as vacuum systems and dust extraction units, to maintain a clean and sterile filling environment. The filling process for powders typically involves the use of augers or volumetric fillers, which are capable of accurately measuring and dispensing the required amount of product into each container. This precision is essential for maintaining product quality and ensuring compliance with industry regulations. Both liquid and powder aseptic filling machines are designed to accommodate a variety of container types and sizes, providing flexibility for manufacturers to meet diverse market demands. The ability to switch between different products and packaging formats is a key advantage of aseptic filling technology, allowing businesses to adapt to changing consumer preferences and market trends. Furthermore, the use of aseptic filling machines helps to reduce the risk of product recalls and enhance brand reputation by ensuring that products are safe, high-quality, and free from contaminants. As consumer demand for safe and long-lasting products continues to grow, the Global Aseptic Filling Machine Market is poised to play an increasingly important role in the packaging industry, providing innovative solutions for the filling of both liquids and powders.

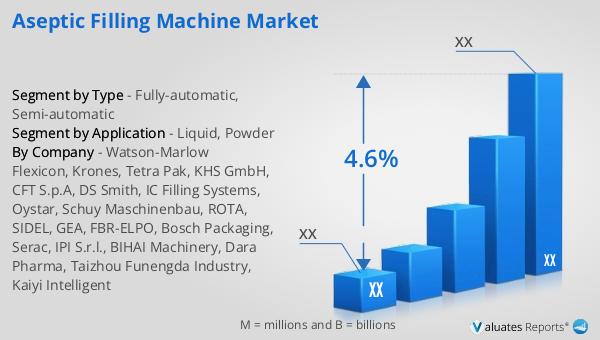

Global Aseptic Filling Machine Market Outlook:

In 2024, the global market size for Aseptic Filling Machines was valued at approximately $1,038 million, with projections indicating growth to around $1,415 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold about 50% of the market share. Among the various product types, fully-automatic aseptic filling machines represent the largest segment, accounting for approximately 65% of the market. This dominance is largely due to the efficiency and precision offered by fully-automatic systems, which are essential for high-volume production environments where maintaining sterility and minimizing contamination risks are critical. The preference for fully-automatic machines is also driven by their ability to operate continuously with minimal human intervention, making them ideal for industries such as pharmaceuticals and large-scale food and beverage production. As the demand for safe and long-lasting products continues to rise, the Global Aseptic Filling Machine Market is expected to see sustained growth, with fully-automatic machines playing a pivotal role in meeting the needs of the packaging industry.

| Report Metric | Details |

| Report Name | Aseptic Filling Machine Market |

| CAGR | 4.6% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Watson-Marlow Flexicon, Krones, Tetra Pak, KHS GmbH, CFT S.p.A, DS Smith, IC Filling Systems, Oystar, Schuy Maschinenbau, ROTA, SIDEL, GEA, FBR-ELPO, Bosch Packaging, Serac, IPI S.r.l., BIHAI Machinery, Dara Pharma, Taizhou Funengda Industry, Kaiyi Intelligent |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |