What is Global Vinyl Terminated Polydimethylsiloxane Market?

The Global Vinyl Terminated Polydimethylsiloxane Market is a specialized segment within the broader silicone industry, focusing on a unique type of silicone polymer. Vinyl Terminated Polydimethylsiloxane (VTPDMS) is a silicone compound characterized by vinyl groups at the terminal ends of its molecular structure. This chemical configuration imparts specific properties to the polymer, making it highly versatile and valuable across various industrial applications. VTPDMS is known for its excellent thermal stability, flexibility, and resistance to environmental factors such as UV radiation and moisture. These attributes make it an ideal choice for industries that require durable and reliable materials. The market for VTPDMS is driven by its extensive use in sectors such as electronics, automotive, construction, and healthcare, where it is employed in the production of sealants, adhesives, coatings, and elastomers. As industries continue to demand materials that can withstand harsh conditions while maintaining performance, the Global Vinyl Terminated Polydimethylsiloxane Market is poised for growth, driven by innovation and the development of new applications. The market's expansion is also supported by the increasing demand for high-performance materials in emerging economies, where industrialization and technological advancements are on the rise.

in the Global Vinyl Terminated Polydimethylsiloxane Market:

In the Global Vinyl Terminated Polydimethylsiloxane Market, various types of VTPDMS are utilized by customers based on their specific needs and applications. These types are primarily distinguished by their viscosity, which affects their processing and performance characteristics. Viscosity is a measure of a fluid's resistance to flow, and in the case of VTPDMS, it plays a crucial role in determining how the material can be used. The market is segmented into different viscosity ranges, each catering to distinct applications. For instance, VTPDMS with a viscosity below 500 is the largest segment, accounting for about 40% of the market. This low-viscosity type is favored for applications that require easy processing and spreading, such as in coatings and sealants. Its ability to flow smoothly makes it ideal for creating thin, even layers that provide protection and durability. On the other hand, VTPDMS with higher viscosities is used in applications where more robust mechanical properties are needed. These include the production of elastomers and rubber components that require greater strength and flexibility. The choice of viscosity is often dictated by the end-use requirements, with manufacturers selecting the appropriate type to achieve the desired balance of performance and processability. Additionally, the market is influenced by the specific needs of different industries. In the electronics sector, for example, VTPDMS is used in encapsulants and potting compounds that protect sensitive components from environmental damage. The material's excellent dielectric properties and thermal stability make it an ideal choice for these applications. Similarly, in the automotive industry, VTPDMS is used in the production of gaskets, seals, and hoses that must withstand high temperatures and exposure to chemicals. The construction industry also relies on VTPDMS for its weather-resistant properties, using it in sealants and adhesives that provide long-lasting protection against the elements. In healthcare, VTPDMS is used in medical devices and implants, where its biocompatibility and flexibility are critical. The market's diversity is further enhanced by the development of customized VTPDMS formulations that meet specific customer requirements. Manufacturers are continually innovating to create new types of VTPDMS with enhanced properties, such as improved adhesion, increased thermal resistance, and greater flexibility. These advancements are driven by the need to address the evolving demands of various industries and to provide solutions that offer superior performance and reliability. As a result, the Global Vinyl Terminated Polydimethylsiloxane Market is characterized by a wide range of products that cater to the diverse needs of its customers, ensuring that there is a suitable type of VTPDMS for every application.

HTV (High Temperature Vulcanized Silicone Rubber), LSR (Liquid Silicone Rubber) in the Global Vinyl Terminated Polydimethylsiloxane Market:

The usage of Global Vinyl Terminated Polydimethylsiloxane Market in HTV (High Temperature Vulcanized Silicone Rubber) and LSR (Liquid Silicone Rubber) is significant due to the unique properties that VTPDMS imparts to these materials. HTV silicone rubber is known for its ability to withstand high temperatures, making it ideal for applications in harsh environments. VTPDMS is a key component in the formulation of HTV silicone rubber, providing the necessary thermal stability and flexibility. The vinyl groups in VTPDMS allow for cross-linking during the vulcanization process, resulting in a robust and durable material that can maintain its properties even under extreme conditions. This makes HTV silicone rubber suitable for use in automotive and aerospace applications, where components are exposed to high temperatures and mechanical stress. In the automotive industry, HTV silicone rubber is used in the production of gaskets, seals, and hoses that must perform reliably in engine compartments and exhaust systems. The material's resistance to heat and chemicals ensures that these components can withstand the demanding conditions they encounter. Similarly, in the aerospace sector, HTV silicone rubber is used in seals and insulation materials that must endure the rigors of flight. The material's ability to maintain its properties at high altitudes and in varying temperatures makes it an essential component in aircraft design. On the other hand, LSR (Liquid Silicone Rubber) is a versatile material that is used in a wide range of applications due to its excellent flow properties and ease of processing. VTPDMS plays a crucial role in the formulation of LSR, providing the necessary flexibility and durability. The low viscosity of VTPDMS allows for easy injection molding, making it ideal for the production of complex and intricate parts. LSR is widely used in the medical industry for the production of medical devices and implants, where its biocompatibility and flexibility are critical. The material's ability to be molded into precise shapes ensures that it can meet the stringent requirements of medical applications. Additionally, LSR is used in the production of consumer goods, such as kitchenware and baby products, where its non-toxic and heat-resistant properties are highly valued. The electronics industry also benefits from the use of LSR, as it is used in the production of keypads, connectors, and other components that require precision and durability. The material's excellent electrical insulation properties make it an ideal choice for these applications. Overall, the usage of VTPDMS in HTV and LSR highlights the versatility and importance of this material in various industries. Its ability to enhance the performance and durability of silicone rubber products makes it a valuable component in the production of high-quality materials that meet the demanding requirements of modern applications.

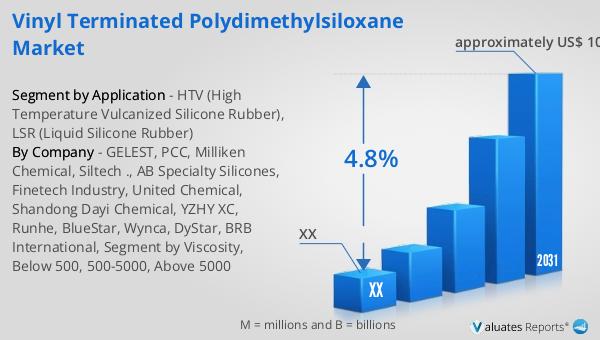

Global Vinyl Terminated Polydimethylsiloxane Market Outlook:

In 2024, the global market size for Vinyl Terminated Polydimethylsiloxane was valued at approximately US$ 740 million. This market is projected to grow significantly, reaching an estimated value of around US$ 1,022 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold about 45% of the market share. Geographically, China represents the largest market, accounting for approximately 40% of the global share. This is followed by North America, which holds a share of about 35%. In terms of product segmentation, the category of Viscosity Below 500 emerges as the largest segment, capturing around 40% of the market. This segment's prominence is attributed to its widespread application across various industries due to its favorable processing characteristics. The market dynamics are shaped by the demand for high-performance materials that can meet the rigorous requirements of diverse applications. As industries continue to evolve and seek advanced materials, the Global Vinyl Terminated Polydimethylsiloxane Market is poised for sustained growth, driven by innovation and the development of new applications.

| Report Metric | Details |

| Report Name | Vinyl Terminated Polydimethylsiloxane Market |

| Forecasted market size in 2031 | approximately US$ 1022 million |

| CAGR | 4.8% |

| Forecasted years | 2025 - 2031 |

| Segment by Application |

|

| By Region |

|

| By Company | GELEST, PCC, Milliken Chemical, Siltech ., AB Specialty Silicones, Finetech Industry, United Chemical, Shandong Dayi Chemical, YZHY XC, Runhe, BlueStar, Wynca, DyStar, BRB International, Segment by Viscosity, Below 500, 500-5000, Above 5000 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |