What is Global Stepper Ball Screw Market?

The Global Stepper Ball Screw Market is a specialized segment within the broader mechanical components industry. Stepper ball screws are precision mechanical devices used to convert rotational motion into linear motion with high accuracy and efficiency. These components are essential in various applications, including industrial automation, medical devices, and printing equipment, among others. The market for stepper ball screws is driven by the increasing demand for automation and precision in manufacturing processes. As industries strive for higher efficiency and productivity, the need for reliable and accurate motion control systems becomes paramount. Stepper ball screws offer the advantage of precise positioning and repeatability, making them indispensable in applications where accuracy is critical. The global market for these components is characterized by technological advancements, increasing adoption in emerging markets, and a growing emphasis on energy-efficient solutions.

Internal Circulation Ballscrew, External Circulation Ballscrew in the Global Stepper Ball Screw Market:

Internal circulation ballscrews and external circulation ballscrews are two primary types of ballscrews used in the Global Stepper Ball Screw Market. Internal circulation ballscrews feature a design where the ball bearings circulate within the nut, providing a compact and efficient solution for linear motion. This design minimizes the risk of contamination and wear, making it suitable for applications requiring high precision and reliability. On the other hand, external circulation ballscrews have ball bearings that circulate outside the nut, typically through a return tube or channel. This design allows for higher load capacities and longer travel lengths, making it ideal for heavy-duty applications. Both types of ballscrews are essential in various industries, including industrial automation, where they enable precise control of machinery and equipment. In printing equipment, ballscrews ensure accurate positioning of print heads and other components, resulting in high-quality prints. In medical devices, ballscrews are used in applications such as surgical robots and diagnostic equipment, where precision and reliability are crucial. The choice between internal and external circulation ballscrews depends on the specific requirements of the application, including load capacity, travel length, and environmental conditions. As the demand for automation and precision continues to grow, the Global Stepper Ball Screw Market is expected to see increased adoption of both internal and external circulation ballscrews, driven by advancements in technology and the need for efficient and reliable motion control solutions.

Industrial Automation, Printing Equipment, Medical Devices, Others in the Global Stepper Ball Screw Market:

The usage of stepper ball screws in industrial automation is extensive, as they play a crucial role in enhancing the precision and efficiency of automated systems. In manufacturing plants, stepper ball screws are used in CNC machines, robotic arms, and assembly lines to ensure accurate and repeatable movements. This precision is vital for producing high-quality products and reducing waste. In the printing equipment industry, stepper ball screws are used to control the movement of print heads and other components, ensuring precise positioning and high-quality prints. The ability to achieve fine adjustments and maintain consistent performance makes stepper ball screws an essential component in modern printing machines. In the medical devices sector, stepper ball screws are used in various applications, including surgical robots, diagnostic equipment, and patient positioning systems. The high precision and reliability of stepper ball screws are critical in these applications, where even the slightest error can have significant consequences. Additionally, stepper ball screws are used in other industries, such as aerospace, automotive, and consumer electronics, where precise linear motion is required. The versatility and reliability of stepper ball screws make them a preferred choice for a wide range of applications, driving their demand in the global market.

Global Stepper Ball Screw Market Outlook:

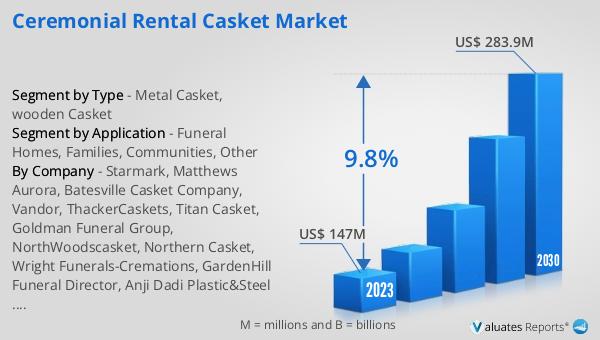

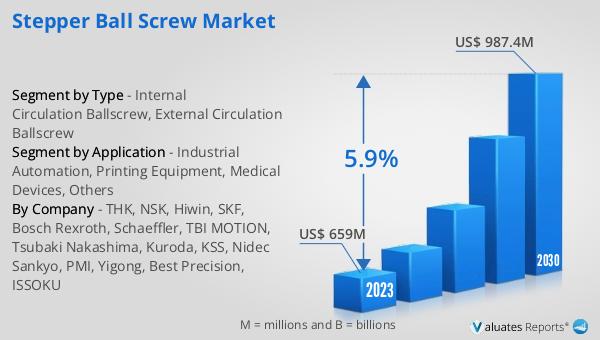

The global Stepper Ball Screw market was valued at US$ 659 million in 2023 and is anticipated to reach US$ 987.4 million by 2030, witnessing a CAGR of 5.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for precision and automation in various industries, including manufacturing, medical devices, and printing equipment. The market is characterized by technological advancements, which are enhancing the performance and efficiency of stepper ball screws. As industries continue to adopt automation and precision engineering, the demand for reliable and accurate motion control systems is expected to rise. The growing emphasis on energy-efficient solutions is also contributing to the market's growth, as stepper ball screws offer high efficiency and low energy consumption. The market's expansion is further supported by the increasing adoption of stepper ball screws in emerging markets, where industrialization and automation are on the rise. Overall, the global Stepper Ball Screw market is poised for significant growth in the coming years, driven by the need for precision, efficiency, and reliability in various applications.

| Report Metric | Details |

| Report Name | Stepper Ball Screw Market |

| Accounted market size in 2023 | US$ 659 million |

| Forecasted market size in 2030 | US$ 987.4 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | THK, NSK, Hiwin, SKF, Bosch Rexroth, Schaeffler, TBI MOTION, Tsubaki Nakashima, Kuroda, KSS, Nidec Sankyo, PMI, Yigong, Best Precision, ISSOKU |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |