What is Global Food Heat Sealing Machine Market?

The Global Food Heat Sealing Machine Market refers to the industry that manufactures and sells machines designed to seal food packaging using heat. These machines are essential for ensuring the freshness, safety, and longevity of food products by creating airtight seals that prevent contamination and spoilage. The market encompasses a wide range of machines, from small, manual devices used in households to large, automated systems employed in industrial settings. The demand for these machines is driven by the growing need for efficient food packaging solutions, especially in the face of increasing global food consumption and the rising importance of food safety standards. Technological advancements have also played a significant role in the market's growth, with modern heat sealing machines offering enhanced precision, speed, and energy efficiency. As a result, the Global Food Heat Sealing Machine Market is a dynamic and evolving sector, catering to diverse needs across various segments of the food industry.

Automatic Heat Sealers, Semi-Automatic Heat Sealers in the Global Food Heat Sealing Machine Market:

Automatic heat sealers and semi-automatic heat sealers are two primary categories within the Global Food Heat Sealing Machine Market, each serving distinct purposes and offering unique advantages. Automatic heat sealers are designed for high-volume operations, typically found in large-scale food processing plants and packaging facilities. These machines are fully automated, meaning they require minimal human intervention once set up. They can handle a continuous flow of products, sealing them quickly and efficiently. The automation ensures consistent seal quality, reduces labor costs, and increases overall productivity. These machines often come equipped with advanced features such as programmable settings, temperature controls, and sensors that detect and correct any sealing errors. On the other hand, semi-automatic heat sealers strike a balance between manual and automatic operations. They are ideal for medium to small-scale businesses that require a certain level of automation but still need some degree of manual control. These machines typically require an operator to place the packaging material in the sealing area and initiate the sealing process. While they may not match the speed and efficiency of fully automatic machines, semi-automatic heat sealers offer greater flexibility and are generally more affordable. They are particularly useful in settings where product variety and packaging sizes frequently change, as they can be easily adjusted to accommodate different requirements. Both types of heat sealers play a crucial role in the food industry, ensuring that products are securely packaged to maintain freshness and prevent contamination. The choice between automatic and semi-automatic heat sealers depends largely on the specific needs and scale of the operation. For instance, a large food manufacturer with a high production volume would benefit more from an automatic heat sealer, while a smaller artisanal food producer might find a semi-automatic machine more suitable. Regardless of the type, the primary goal of these machines is to provide reliable and efficient sealing solutions that enhance the shelf life and safety of food products.

Household, Commercial, Industry in the Global Food Heat Sealing Machine Market:

The usage of Global Food Heat Sealing Machines spans across various sectors, including household, commercial, and industrial settings, each with its unique requirements and benefits. In households, these machines are often used for sealing leftovers, snacks, and other perishable items to extend their shelf life and maintain freshness. Small, manual or semi-automatic heat sealers are typically preferred in this setting due to their ease of use and affordability. They help reduce food waste by allowing families to store food safely for longer periods, which is particularly beneficial in today's fast-paced lifestyle where meal prepping and bulk buying are common practices. In commercial settings, such as restaurants, cafes, and catering services, heat sealing machines play a crucial role in food preparation and storage. These establishments often deal with large quantities of food that need to be stored and transported safely. Semi-automatic and automatic heat sealers are commonly used here to ensure that food items are securely packaged, preventing contamination and spoilage. This not only helps in maintaining the quality of the food but also in complying with health and safety regulations. The ability to seal food quickly and efficiently also aids in streamlining operations, reducing labor costs, and improving overall productivity. In industrial settings, such as food processing plants and packaging facilities, the demand for heat sealing machines is even more pronounced. These environments require high-speed, high-volume sealing solutions to keep up with the massive production demands. Automatic heat sealers are the go-to choice in these settings due to their ability to handle continuous operations with minimal human intervention. They are equipped with advanced features like programmable settings, temperature controls, and error detection systems to ensure consistent and high-quality seals. The use of these machines in industrial settings not only enhances the efficiency of the packaging process but also ensures that the food products meet stringent quality and safety standards. Overall, the Global Food Heat Sealing Machine Market caters to a wide range of applications, each with its specific needs and benefits. Whether it's extending the shelf life of leftovers in a household, ensuring the safe storage and transportation of food in a commercial kitchen, or meeting the high-volume demands of an industrial food processing plant, these machines play a vital role in maintaining the quality and safety of food products.

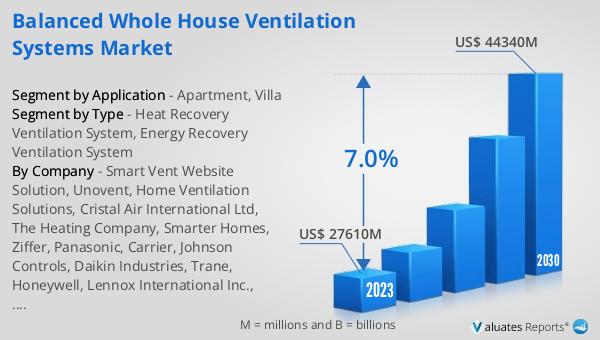

Global Food Heat Sealing Machine Market Outlook:

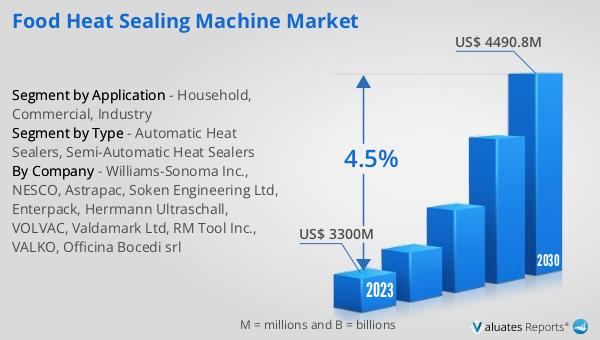

The global Food Heat Sealing Machine market was valued at US$ 3300 million in 2023 and is anticipated to reach US$ 4490.8 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the industry, driven by increasing demand for efficient food packaging solutions across various sectors. The rising awareness about food safety and the need to extend the shelf life of food products are key factors contributing to this growth. Technological advancements in heat sealing machines, such as improved automation, precision, and energy efficiency, are also playing a crucial role in driving the market forward. As more businesses and households recognize the benefits of using heat sealing machines, the market is expected to expand further, offering numerous opportunities for manufacturers and suppliers. The projected growth rate underscores the importance of these machines in the food industry and their potential to revolutionize food packaging practices globally.

| Report Metric | Details |

| Report Name | Food Heat Sealing Machine Market |

| Accounted market size in 2023 | US$ 3300 million |

| Forecasted market size in 2030 | US$ 4490.8 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Williams-Sonoma Inc., NESCO, Astrapac, Soken Engineering Ltd, Enterpack, Herrmann Ultraschall, VOLVAC, Valdamark Ltd, RM Tool Inc., VALKO, Officina Bocedi srl |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |