What is Global Large Industrial Air Compressors Market?

The Global Large Industrial Air Compressors Market refers to the worldwide industry focused on the production, distribution, and utilization of large-scale air compressors used in various industrial applications. These air compressors are essential for converting power into potential energy stored in pressurized air, which is then used to power machinery, tools, and other equipment. The market encompasses a wide range of compressor types, including reciprocating, rotary, and centrifugal compressors, each designed to meet specific industrial needs. The demand for large industrial air compressors is driven by their critical role in enhancing operational efficiency, reducing downtime, and ensuring the smooth functioning of industrial processes. Industries such as manufacturing, automotive, food and beverage, and railroads rely heavily on these compressors for their day-to-day operations. The market is characterized by continuous technological advancements aimed at improving energy efficiency, reducing environmental impact, and enhancing overall performance. As industries continue to expand and modernize, the global large industrial air compressors market is expected to grow, driven by the increasing need for reliable and efficient compressed air solutions.

Reciprocating, Rotary, Centrifugal in the Global Large Industrial Air Compressors Market:

Reciprocating, rotary, and centrifugal compressors are the three primary types of air compressors used in the Global Large Industrial Air Compressors Market, each with distinct characteristics and applications. Reciprocating compressors, also known as piston compressors, operate by using a piston within a cylinder to compress air. These compressors are known for their high-pressure capabilities and are commonly used in applications requiring intermittent use, such as in automotive repair shops and small manufacturing facilities. They are valued for their durability and ability to deliver high-pressure air, making them suitable for heavy-duty tasks. However, they can be noisy and require regular maintenance to ensure optimal performance. Rotary compressors, on the other hand, use rotating elements to compress air. The most common types of rotary compressors are rotary screw and rotary vane compressors. Rotary screw compressors use two helical screws to compress air, making them ideal for continuous operation in industrial settings. They are known for their efficiency, reliability, and ability to deliver a steady flow of compressed air. Rotary vane compressors, which use a series of vanes mounted on a rotor, are also used in various industrial applications. These compressors are appreciated for their compact design, low noise levels, and ease of maintenance. Rotary compressors are widely used in industries such as manufacturing, construction, and food processing, where a continuous supply of compressed air is essential. Centrifugal compressors, also known as dynamic compressors, use a high-speed rotating impeller to impart velocity to the air, which is then converted into pressure. These compressors are capable of delivering large volumes of compressed air at high pressures, making them suitable for large-scale industrial applications. Centrifugal compressors are known for their high efficiency, low maintenance requirements, and ability to handle large airflows. They are commonly used in industries such as petrochemical, power generation, and HVAC (heating, ventilation, and air conditioning) systems. Due to their complex design and high initial cost, centrifugal compressors are typically used in applications where the demand for compressed air is constant and substantial. Each type of compressor has its own set of advantages and limitations, making them suitable for different industrial applications. Reciprocating compressors are ideal for high-pressure, intermittent use, while rotary compressors are preferred for continuous operation and steady airflow. Centrifugal compressors, with their ability to handle large volumes of air, are best suited for large-scale industrial processes. The choice of compressor depends on factors such as the required pressure, volume of air, and specific application needs. As industries continue to evolve, the demand for efficient and reliable air compressors will drive innovation and development in the Global Large Industrial Air Compressors Market.

Automotive Industry, Railroad Industry, Food Industry in the Global Large Industrial Air Compressors Market:

The usage of large industrial air compressors in the automotive industry is extensive and multifaceted. These compressors are essential for powering pneumatic tools used in assembly lines, such as impact wrenches, drills, and paint sprayers. They ensure that the production process is efficient and that vehicles are assembled with precision. In addition to powering tools, air compressors are also used in the testing and quality control stages of automotive manufacturing. They provide the necessary air pressure for testing components such as brakes, tires, and suspension systems, ensuring that each vehicle meets safety and performance standards. Furthermore, air compressors are used in the maintenance and repair of vehicles, providing the power needed for tasks such as tire inflation, engine cleaning, and air conditioning system servicing. In the railroad industry, large industrial air compressors play a crucial role in the operation and maintenance of trains. They are used to power pneumatic braking systems, which are essential for the safe and efficient operation of trains. These compressors provide the necessary air pressure to activate the brakes, ensuring that trains can stop quickly and safely when needed. In addition to braking systems, air compressors are also used in the operation of train doors, pantographs, and other pneumatic systems. They ensure that these systems function reliably and efficiently, contributing to the overall safety and performance of the railroad industry. Furthermore, air compressors are used in the maintenance and repair of trains, providing the power needed for tasks such as cleaning, painting, and component testing. The food industry also relies heavily on large industrial air compressors for various applications. In food processing plants, air compressors are used to power pneumatic machinery and equipment, such as conveyors, packaging machines, and filling machines. They ensure that the production process is efficient and that food products are handled with care and precision. Air compressors are also used in the cleaning and sanitation of food processing equipment, providing the necessary air pressure for tasks such as blow-off cleaning and air knife drying. In addition to processing and cleaning, air compressors are used in the storage and transportation of food products. They provide the necessary air pressure for tasks such as refrigeration, vacuum packaging, and pneumatic conveying, ensuring that food products are stored and transported safely and efficiently. Overall, the usage of large industrial air compressors in the automotive, railroad, and food industries is essential for ensuring the efficiency, safety, and reliability of various processes and operations. These compressors provide the necessary power for a wide range of applications, from powering tools and machinery to testing and quality control. As industries continue to evolve and modernize, the demand for reliable and efficient air compressors will continue to grow, driving innovation and development in the Global Large Industrial Air Compressors Market.

Global Large Industrial Air Compressors Market Outlook:

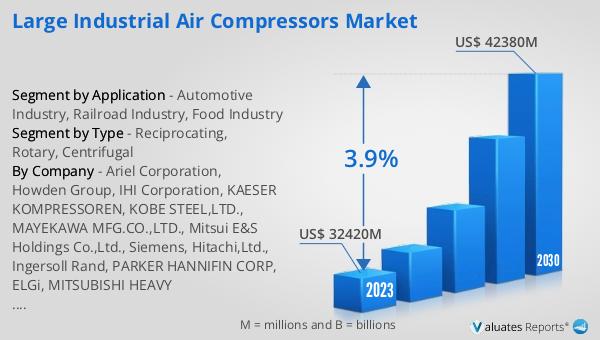

The global Large Industrial Air Compressors market was valued at US$ 32,420 million in 2023 and is anticipated to reach US$ 42,380 million by 2030, witnessing a CAGR of 3.9% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the large industrial air compressors market over the next several years. The projected increase in market value reflects the rising demand for efficient and reliable air compression solutions across various industries. As industrial processes become more complex and the need for high-performance equipment grows, the market for large industrial air compressors is expected to expand. The anticipated compound annual growth rate (CAGR) of 3.9% indicates steady and sustained growth, driven by factors such as technological advancements, increasing industrialization, and the need for energy-efficient solutions. This positive market outlook underscores the importance of large industrial air compressors in enhancing operational efficiency and supporting the growth of key industries worldwide.

| Report Metric | Details |

| Report Name | Large Industrial Air Compressors Market |

| Accounted market size in 2023 | US$ 32420 million |

| Forecasted market size in 2030 | US$ 42380 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ariel Corporation, Howden Group, IHI Corporation, KAESER KOMPRESSOREN, KOBE STEEL,LTD., MAYEKAWA MFG.CO.,LTD., Mitsui E&S Holdings Co.,Ltd., Siemens, Hitachi,Ltd., Ingersoll Rand, PARKER HANNIFIN CORP, ELGi, MITSUBISHI HEAVY INDUSTRIES,LTD., Sulzer., Danfoss |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |