What is Biopharma Freeze Dryer Machine - Global Market?

Biopharma freeze dryer machines are essential tools in the global market, primarily used in the pharmaceutical and biotechnology industries to preserve biological materials. These machines operate on the principle of lyophilization, which involves freezing a product and then reducing the surrounding pressure to allow the frozen water in the product to sublimate directly from the solid phase to the gas phase. This process is crucial for maintaining the stability and integrity of sensitive biological products, such as vaccines, antibodies, and other biopharmaceuticals. The global market for biopharma freeze dryer machines is driven by the increasing demand for biopharmaceuticals, which require precise and reliable preservation methods. As the pharmaceutical industry continues to grow, particularly with the rise of personalized medicine and biologics, the need for advanced freeze-drying technology becomes more pronounced. These machines are designed to handle a wide range of products, from small-scale laboratory samples to large-scale industrial batches, making them versatile and indispensable in the biopharmaceutical sector. The market is characterized by continuous technological advancements, with manufacturers focusing on improving efficiency, automation, and scalability to meet the evolving needs of the industry.

Single Stage Refrigeration Compression Cycle, Two-stage Refrigeration Compression Cycle in the Biopharma Freeze Dryer Machine - Global Market:

The refrigeration compression cycle is a critical component of biopharma freeze dryer machines, ensuring the effective removal of heat during the lyophilization process. In a single-stage refrigeration compression cycle, the process begins with the refrigerant entering the compressor as a low-pressure gas. The compressor then compresses the gas, raising its pressure and temperature. This high-pressure, high-temperature gas then flows into the condenser, where it releases heat to the surroundings and condenses into a liquid. The liquid refrigerant then passes through an expansion valve, where it experiences a drop in pressure and temperature, turning into a low-pressure, low-temperature mixture of liquid and vapor. This cold refrigerant then enters the evaporator, where it absorbs heat from the product chamber, causing the refrigerant to evaporate and cool the chamber. The cycle then repeats as the refrigerant returns to the compressor. This single-stage cycle is suitable for applications where moderate cooling is sufficient. In contrast, a two-stage refrigeration compression cycle is employed in biopharma freeze dryer machines when lower temperatures are required, such as for more sensitive biological materials. This cycle involves two compressors and two condensers, allowing for a more efficient and effective cooling process. The first stage of the cycle operates similarly to the single-stage cycle, with the refrigerant being compressed, condensed, and expanded. However, instead of entering the evaporator, the refrigerant from the first stage enters a second compressor, where it is further compressed to an even higher pressure and temperature. This high-pressure gas then flows into a second condenser, where it releases additional heat and condenses into a liquid. The liquid refrigerant then passes through a second expansion valve, where it experiences another drop in pressure and temperature. This results in an even colder refrigerant entering the evaporator, providing the necessary cooling for the product chamber. The two-stage cycle is particularly beneficial for freeze-drying processes that require extremely low temperatures, ensuring the stability and integrity of highly sensitive biopharmaceutical products. Both single-stage and two-stage refrigeration compression cycles play a vital role in the operation of biopharma freeze dryer machines, each offering distinct advantages depending on the specific requirements of the freeze-drying process. The choice between the two cycles depends on factors such as the desired temperature range, the sensitivity of the product being dried, and the scale of the operation. As the demand for biopharmaceuticals continues to grow, the need for efficient and reliable freeze-drying technology becomes increasingly important. Manufacturers of biopharma freeze dryer machines are continually innovating to improve the performance and efficiency of these refrigeration cycles, ensuring that they can meet the evolving needs of the pharmaceutical and biotechnology industries. By optimizing the refrigeration compression cycle, these machines can provide precise and consistent cooling, which is essential for maintaining the quality and efficacy of biopharmaceutical products.

Biology Laboratory, Pharmaceutical Factory, Others in the Biopharma Freeze Dryer Machine - Global Market:

Biopharma freeze dryer machines are widely used in various sectors, including biology laboratories, pharmaceutical factories, and other industries that require the preservation of sensitive biological materials. In biology laboratories, these machines are essential for preserving samples such as proteins, enzymes, and nucleic acids. The freeze-drying process helps maintain the structural integrity and biological activity of these samples, allowing researchers to store them for extended periods without degradation. This is particularly important for experiments that require consistent and reliable results, as well as for the long-term storage of valuable biological materials. The ability to preserve samples in a stable and reproducible manner is crucial for advancing research and development in the life sciences. In pharmaceutical factories, biopharma freeze dryer machines play a critical role in the production of biopharmaceuticals, including vaccines, antibodies, and other therapeutic proteins. The freeze-drying process is used to remove water from these products, ensuring their stability and shelf life. This is especially important for products that are sensitive to temperature and humidity, as freeze-drying helps maintain their potency and efficacy. By preserving the active ingredients in a stable and dry form, pharmaceutical companies can ensure that their products remain effective throughout their shelf life, even under varying storage conditions. Additionally, freeze-dried products are often easier to transport and handle, as they are less susceptible to damage from temperature fluctuations and mechanical stress. Beyond biology laboratories and pharmaceutical factories, biopharma freeze dryer machines are also used in other industries that require the preservation of sensitive materials. For example, in the food industry, freeze-drying is used to preserve the flavor, texture, and nutritional content of various food products, such as fruits, vegetables, and coffee. This process helps extend the shelf life of these products while maintaining their quality and taste. Similarly, in the cosmetics industry, freeze-drying is used to preserve the active ingredients in skincare and beauty products, ensuring their stability and effectiveness. By removing water from these products, manufacturers can prevent microbial growth and degradation, resulting in longer-lasting and more effective products. Overall, the versatility and effectiveness of biopharma freeze dryer machines make them indispensable tools in a wide range of industries. Their ability to preserve sensitive materials in a stable and reproducible manner is crucial for ensuring the quality and efficacy of various products, from biopharmaceuticals to food and cosmetics. As the demand for high-quality and reliable preservation methods continues to grow, the global market for biopharma freeze dryer machines is expected to expand, driven by advancements in technology and the increasing need for efficient and effective preservation solutions.

Biopharma Freeze Dryer Machine - Global Market Outlook:

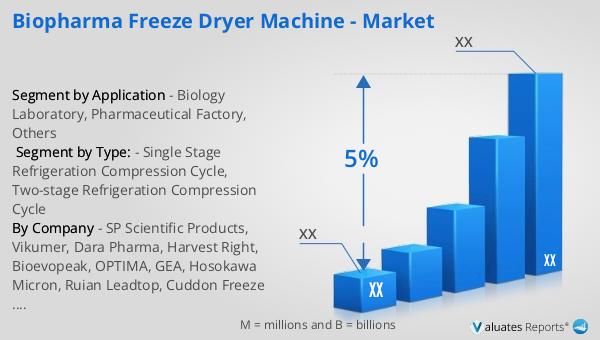

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth reflects the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, the rise of chronic diseases, and advancements in medical technology. In comparison, the chemical drug market has also shown significant growth, with its value increasing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market highlights the ongoing demand for traditional pharmaceuticals, even as the industry shifts towards more innovative and personalized treatments. The expansion of both the pharmaceutical and chemical drug markets underscores the importance of reliable and efficient preservation methods, such as those provided by biopharma freeze dryer machines. As the industry continues to evolve, the need for advanced freeze-drying technology will become increasingly critical to ensure the stability and efficacy of a wide range of pharmaceutical products. This growth trajectory indicates a robust future for the biopharma freeze dryer machine market, as it plays a vital role in supporting the pharmaceutical industry's ongoing development and innovation.

| Report Metric | Details |

| Report Name | Biopharma Freeze Dryer Machine - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SP Scientific Products, Vikumer, Dara Pharma, Harvest Right, Bioevopeak, OPTIMA, GEA, Hosokawa Micron, Ruian Leadtop, Cuddon Freeze Dry, Labfreez Instruments Group, Sheyan Yiqi, Rotech Bioengineering, TOFFON, BIOCOOL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |