What is Global Double Screw Air Compressors Market?

The global Double Screw Air Compressors market is a significant segment within the broader air compressor industry. Double screw air compressors, also known as twin-screw compressors, utilize two interlocking helical rotors to compress air. This technology is favored for its efficiency, reliability, and ability to deliver a continuous supply of compressed air. These compressors are widely used in various industries due to their ability to operate under high pressure and provide a steady flow of air. The market for double screw air compressors is driven by the increasing demand for energy-efficient and low-maintenance air compression solutions. Additionally, advancements in technology and the growing need for automation in industrial processes are contributing to the market's growth. The global market encompasses a wide range of applications, from small-scale operations to large industrial plants, making it a versatile and essential component in modern industrial infrastructure.

Oil Free, Oil Injected in the Global Double Screw Air Compressors Market:

In the realm of double screw air compressors, there are two primary types: oil-free and oil-injected. Oil-free double screw air compressors are designed to provide clean, contaminant-free air, making them ideal for applications where air purity is crucial, such as in the food and beverage, pharmaceutical, and electronics industries. These compressors operate without the use of oil in the compression chamber, which eliminates the risk of oil contamination in the compressed air. This is achieved through the use of advanced materials and coatings that reduce friction and wear, ensuring long-term reliability and efficiency. On the other hand, oil-injected double screw air compressors use oil to lubricate, seal, and cool the compression process. This type of compressor is known for its durability and ability to handle heavy-duty applications. The oil in the system helps to reduce wear and tear on the components, leading to a longer lifespan and lower maintenance costs. Oil-injected compressors are commonly used in industries such as manufacturing, construction, and mining, where the demand for high-pressure air and robust performance is paramount. Both types of compressors have their unique advantages and are chosen based on the specific requirements of the application. The choice between oil-free and oil-injected compressors often comes down to the need for air purity versus the need for durability and cost-effectiveness. As industries continue to evolve and the demand for efficient and reliable air compression solutions grows, both oil-free and oil-injected double screw air compressors will play a crucial role in meeting these needs.

Manufacturing Industry, Oil and Gas Industry, Mining Industry, Construction Industry in the Global Double Screw Air Compressors Market:

Double screw air compressors are extensively used across various industries due to their efficiency and reliability. In the manufacturing industry, these compressors are essential for powering pneumatic tools, machinery, and equipment. They provide a consistent and reliable source of compressed air, which is crucial for maintaining production lines and ensuring the smooth operation of automated systems. In the oil and gas industry, double screw air compressors are used for a variety of applications, including drilling, pipeline maintenance, and gas processing. Their ability to operate under high pressure and provide a continuous flow of air makes them ideal for these demanding environments. In the mining industry, these compressors are used for drilling, blasting, and material handling. The robust design and high performance of double screw air compressors make them suitable for the harsh conditions often encountered in mining operations. In the construction industry, double screw air compressors are used to power pneumatic tools, such as jackhammers and nail guns, as well as for sandblasting and painting. Their portability and ability to deliver high-pressure air make them a valuable asset on construction sites. Overall, the versatility and reliability of double screw air compressors make them an indispensable tool across a wide range of industries.

Global Double Screw Air Compressors Market Outlook:

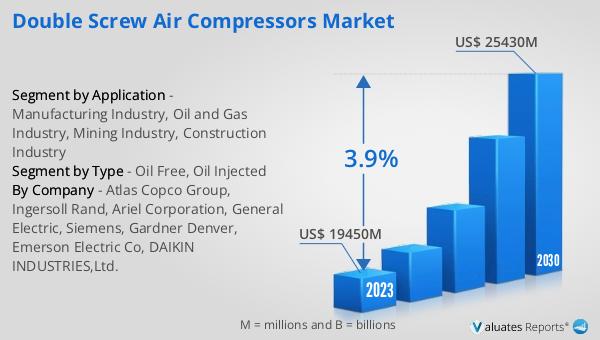

The global Double Screw Air Compressors market was valued at US$ 19,450 million in 2023 and is projected to reach US$ 25,430 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable air compression solutions across various industries. The market's expansion can be attributed to several factors, including technological advancements, the need for energy-efficient systems, and the growing automation in industrial processes. As industries continue to seek ways to improve productivity and reduce operational costs, the adoption of double screw air compressors is expected to rise. These compressors offer numerous benefits, such as reduced maintenance requirements, longer lifespan, and the ability to operate under high pressure, making them a preferred choice for many applications. The projected growth of the market underscores the importance of double screw air compressors in modern industrial infrastructure and highlights the ongoing trend towards more efficient and sustainable industrial practices.

| Report Metric | Details |

| Report Name | Double Screw Air Compressors Market |

| Accounted market size in 2023 | US$ 19450 million |

| Forecasted market size in 2030 | US$ 25430 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco Group, Ingersoll Rand, Ariel Corporation, General Electric, Siemens, Gardner Denver, Emerson Electric Co, DAIKIN INDUSTRIES,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |