What is Global Hydrofluoric Acid Processing Valves Market?

The Global Hydrofluoric Acid Processing Valves Market is a specialized segment within the broader industrial valves market, focusing on valves designed to handle hydrofluoric acid (HF). Hydrofluoric acid is a highly corrosive and toxic substance used in various industrial processes, including petroleum refining, chemical manufacturing, and other alkylation processes. Due to its corrosive nature, the valves used in hydrofluoric acid processing must be made from materials that can withstand the harsh conditions and prevent leaks or failures. These valves are crucial for ensuring the safe and efficient operation of facilities that handle hydrofluoric acid. The market for these specialized valves is driven by the demand from industries that use hydrofluoric acid in their processes, as well as the need for regular maintenance and replacement of existing valves to ensure safety and compliance with regulatory standards. The market encompasses various types of valves, including check valves, gate valves, globe valves, and plug valves, each serving specific functions within the processing systems.

HF Check Valves, HF Gate Valves, HF Globe Valves, HF Plug Valves, Others in the Global Hydrofluoric Acid Processing Valves Market:

HF Check Valves, HF Gate Valves, HF Globe Valves, HF Plug Valves, and other types of valves play critical roles in the Global Hydrofluoric Acid Processing Valves Market. HF Check Valves are designed to allow fluid to flow in one direction only, preventing backflow that could cause contamination or damage to the system. These valves are essential in maintaining the integrity of the processing system by ensuring that hydrofluoric acid flows in the intended direction. HF Gate Valves are used to start or stop the flow of hydrofluoric acid within the system. They operate by lifting a gate out of the path of the fluid, providing a clear and unobstructed flow when fully open. These valves are particularly useful in applications where a straight-line flow and minimal restriction are required. HF Globe Valves are used for regulating the flow of hydrofluoric acid. They consist of a movable disk-type element and a stationary ring seat in a generally spherical body. These valves are ideal for applications where precise control of flow rate is necessary. HF Plug Valves are quarter-turn valves that use a cylindrical or conically tapered plug to control the flow of hydrofluoric acid. The plug has one or more hollow passageways that allow fluid to flow through the valve when it is in the open position. These valves are known for their simplicity and reliability in handling corrosive fluids. Other types of valves in the hydrofluoric acid processing market include ball valves, butterfly valves, and diaphragm valves, each offering unique advantages depending on the specific requirements of the application. Ball valves provide excellent sealing capabilities and are easy to operate, making them suitable for on-off control applications. Butterfly valves are lightweight and compact, offering quick operation and low-pressure drop, which makes them ideal for large-diameter pipes. Diaphragm valves use a flexible diaphragm to regulate flow, providing a high level of corrosion resistance and making them suitable for handling aggressive chemicals like hydrofluoric acid. Each type of valve in the hydrofluoric acid processing market is designed to meet the stringent requirements of handling this highly corrosive substance, ensuring safety, reliability, and efficiency in industrial processes.

Refinery Plant, Chemical Plant, Other Alkylation Processes in the Global Hydrofluoric Acid Processing Valves Market:

The usage of Global Hydrofluoric Acid Processing Valves Market spans across various industrial sectors, including refinery plants, chemical plants, and other alkylation processes. In refinery plants, hydrofluoric acid is used in the alkylation process to produce high-octane gasoline components. The valves used in these plants must be able to handle the corrosive nature of hydrofluoric acid while ensuring the safe and efficient flow of the substance through the processing system. HF Check Valves, HF Gate Valves, HF Globe Valves, and HF Plug Valves are all used in different stages of the refining process to control the flow, prevent backflow, and regulate the pressure of hydrofluoric acid. In chemical plants, hydrofluoric acid is used in the production of various chemicals, including fluorocarbons, fluoropolymers, and other fluorine-containing compounds. The valves used in these plants must be able to withstand the harsh conditions and corrosive nature of hydrofluoric acid while ensuring the safe and efficient operation of the processing system. HF Check Valves, HF Gate Valves, HF Globe Valves, and HF Plug Valves are all used in different stages of the chemical production process to control the flow, prevent backflow, and regulate the pressure of hydrofluoric acid. Other alkylation processes also rely on hydrofluoric acid as a catalyst to produce high-octane gasoline components. The valves used in these processes must be able to handle the corrosive nature of hydrofluoric acid while ensuring the safe and efficient flow of the substance through the processing system. HF Check Valves, HF Gate Valves, HF Globe Valves, and HF Plug Valves are all used in different stages of the alkylation process to control the flow, prevent backflow, and regulate the pressure of hydrofluoric acid. In all these applications, the valves used in hydrofluoric acid processing must be made from materials that can withstand the corrosive nature of the substance, such as stainless steel, Hastelloy, and other corrosion-resistant alloys. Regular maintenance and replacement of these valves are essential to ensure the safety and efficiency of the processing systems, as well as compliance with regulatory standards. The demand for hydrofluoric acid processing valves is driven by the need for safe and efficient handling of this highly corrosive substance in various industrial processes, making it a critical component of the global industrial valves market.

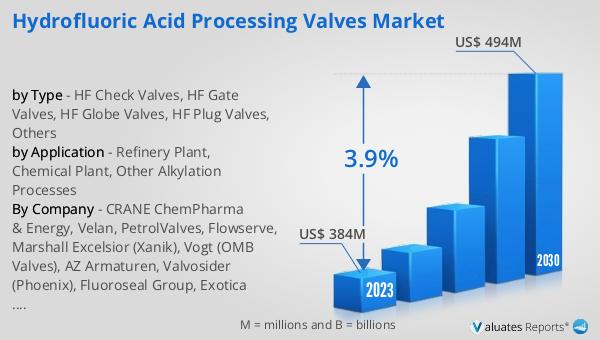

Global Hydrofluoric Acid Processing Valves Market Outlook:

The global Hydrofluoric Acid Processing Valves market was valued at US$ 384 million in 2023 and is anticipated to reach US$ 494 million by 2030, witnessing a CAGR of 3.9% during the forecast period 2024-2030. This market growth reflects the increasing demand for hydrofluoric acid processing valves across various industrial sectors, including refinery plants, chemical plants, and other alkylation processes. The need for safe and efficient handling of hydrofluoric acid, a highly corrosive and toxic substance, drives the demand for specialized valves that can withstand harsh conditions and prevent leaks or failures. The market encompasses various types of valves, including check valves, gate valves, globe valves, and plug valves, each serving specific functions within the processing systems. The growth in this market is also driven by the need for regular maintenance and replacement of existing valves to ensure safety and compliance with regulatory standards. As industries continue to rely on hydrofluoric acid for various processes, the demand for high-quality, corrosion-resistant valves is expected to increase, contributing to the overall growth of the global Hydrofluoric Acid Processing Valves market.

| Report Metric | Details |

| Report Name | Hydrofluoric Acid Processing Valves Market |

| Accounted market size in 2023 | US$ 384 million |

| Forecasted market size in 2030 | US$ 494 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CRANE ChemPharma & Energy, Velan, PetrolValves, Flowserve, Marshall Excelsior (Xanik), Vogt (OMB Valves), AZ Armaturen, Valvosider (Phoenix), Fluoroseal Group, Exotica Valves, Descote Valves |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |