What is Global Cold Milling Machine Market?

The Global Cold Milling Machine Market is a segment of the construction equipment industry that focuses on machines designed to remove asphalt and concrete surfaces. These machines are essential in road construction and maintenance, as they help in the efficient removal of old pavement layers, making way for new surfaces. Cold milling machines are equipped with rotating drums that have sharp cutting tools, which grind and remove the surface material. This process not only prepares the road for resurfacing but also allows for the recycling of the removed material, contributing to sustainable construction practices. The market for these machines is driven by the increasing need for road maintenance and the expansion of road networks worldwide. As urbanization and infrastructure development continue to rise, the demand for efficient and effective road construction equipment like cold milling machines is expected to grow. These machines come in various sizes and configurations, catering to different project requirements, from small-scale urban road repairs to large highway construction projects. The global market is characterized by technological advancements, with manufacturers focusing on improving machine efficiency, reducing operational costs, and enhancing environmental sustainability.

Wheeled Cold Milling Machine, Tracked Cold Milling Machine in the Global Cold Milling Machine Market:

Wheeled Cold Milling Machines and Tracked Cold Milling Machines are two primary types of equipment in the Global Cold Milling Machine Market, each offering distinct advantages and applications. Wheeled Cold Milling Machines are known for their mobility and speed, making them ideal for projects that require frequent relocation or involve large areas. These machines are equipped with rubber tires, allowing them to move quickly between job sites without causing damage to the road surface. They are particularly useful in urban settings where maneuverability and speed are crucial. Wheeled machines are often preferred for projects that require quick completion, as their mobility reduces downtime between tasks. On the other hand, Tracked Cold Milling Machines are designed for stability and precision. They are equipped with tracks instead of wheels, providing better traction and stability on uneven or slippery surfaces. This makes them suitable for challenging terrains and projects that require high precision, such as highway construction or large-scale road rehabilitation. Tracked machines are often used in projects where the surface conditions are less predictable, and stability is a priority. Both types of machines are equipped with advanced features such as automated controls, GPS systems, and dust extraction systems, enhancing their efficiency and environmental friendliness. The choice between wheeled and tracked machines depends on the specific requirements of the project, including the terrain, project size, and desired completion time. Manufacturers in the global market are continuously innovating to improve the performance and versatility of both wheeled and tracked cold milling machines, ensuring they meet the evolving needs of the construction industry.

Road Construction, Public Engineering in the Global Cold Milling Machine Market:

The Global Cold Milling Machine Market plays a crucial role in road construction and public engineering, providing essential equipment for the maintenance and development of infrastructure. In road construction, cold milling machines are used to remove old asphalt or concrete surfaces, preparing the road for resurfacing. This process is vital for maintaining road quality and safety, as it ensures a smooth and even surface for new pavement layers. Cold milling machines are also used in road widening projects, where they help remove existing pavement to make way for additional lanes. The ability to recycle the removed material is a significant advantage, as it reduces waste and lowers the cost of new materials. In public engineering, cold milling machines are used in various infrastructure projects, including the construction and maintenance of bridges, tunnels, and airports. These machines help ensure that surfaces are prepared correctly, contributing to the longevity and durability of the infrastructure. The precision and efficiency of cold milling machines make them indispensable in projects where accuracy and speed are critical. As urbanization and infrastructure development continue to grow, the demand for cold milling machines in road construction and public engineering is expected to increase. The market is characterized by technological advancements, with manufacturers focusing on improving machine efficiency, reducing operational costs, and enhancing environmental sustainability. These advancements ensure that cold milling machines remain a vital tool in the construction and maintenance of infrastructure worldwide.

Global Cold Milling Machine Market Outlook:

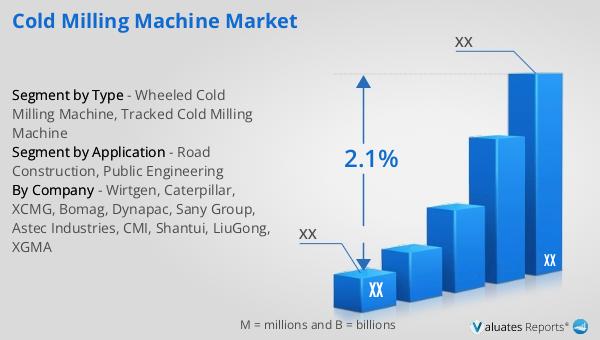

In 2024, the global market size of Cold Milling Machines was valued at approximately US$ 1,151 million. Looking ahead, it is anticipated that this market will grow to around US$ 1,340 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 2.1% during the forecast period from 2025 to 2031. This steady growth can be attributed to several factors, including the increasing demand for road maintenance and infrastructure development worldwide. As urban areas expand and the need for efficient transportation networks grows, the demand for cold milling machines is expected to rise. These machines are essential for maintaining and upgrading road surfaces, ensuring safe and efficient transportation. Additionally, technological advancements in cold milling machines, such as improved efficiency, reduced operational costs, and enhanced environmental sustainability, are likely to drive market growth. Manufacturers are continuously innovating to meet the evolving needs of the construction industry, ensuring that cold milling machines remain a vital tool in infrastructure development. The projected growth in the global cold milling machine market underscores the importance of these machines in the construction and maintenance of infrastructure, highlighting their role in supporting economic development and improving quality of life.

| Report Metric | Details |

| Report Name | Cold Milling Machine Market |

| CAGR | 2.1% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wirtgen, Caterpillar, XCMG, Bomag, Dynapac, Sany Group, Astec Industries, CMI, Shantui, LiuGong, XGMA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |