What is Global Cutting Tool Inserts Market?

The Global Cutting Tool Inserts Market is a crucial segment of the manufacturing industry, providing essential components for machining operations. Cutting tool inserts are replaceable tips used in machine tools to perform cutting, shaping, and finishing tasks on various materials like metals, plastics, and composites. These inserts are designed to withstand high temperatures and pressures, ensuring precision and efficiency in manufacturing processes. The market for cutting tool inserts is driven by the demand for high-quality, durable, and efficient tools that can enhance productivity and reduce downtime in industrial operations. With advancements in technology, cutting tool inserts have evolved to offer better performance, longer life, and greater versatility. The market is characterized by a wide range of products catering to different applications and industries, including automotive, aerospace, energy, and general machinery. As industries continue to seek ways to improve efficiency and reduce costs, the demand for advanced cutting tool inserts is expected to grow, making this market a vital component of the global manufacturing landscape.

Carbide, Ceramics, CBN, Others in the Global Cutting Tool Inserts Market:

Carbide, ceramics, CBN (Cubic Boron Nitride), and other materials form the backbone of the Global Cutting Tool Inserts Market, each offering unique properties that cater to specific industrial needs. Carbide inserts are among the most popular due to their exceptional hardness and wear resistance, making them ideal for high-speed machining and heavy-duty applications. They are composed of tungsten carbide, a compound known for its ability to maintain sharpness and durability under extreme conditions. Carbide inserts are widely used in industries such as automotive and aerospace, where precision and reliability are paramount. On the other hand, ceramic inserts are known for their high-temperature resistance and chemical stability. They are particularly useful in applications involving high-speed cutting and finishing operations, where heat generation is a concern. Ceramics can withstand temperatures that would degrade other materials, making them suitable for machining hard materials like cast iron and superalloys. CBN inserts are another critical component of the cutting tool market, renowned for their hardness second only to diamond. They are particularly effective in machining ferrous materials, offering excellent wear resistance and thermal stability. CBN inserts are often used in the automotive and aerospace industries for tasks that require high precision and surface finish. Additionally, other materials such as polycrystalline diamond (PCD) and high-speed steel (HSS) are also used in cutting tool inserts, each offering distinct advantages. PCD inserts are ideal for non-ferrous materials and composites, providing superior wear resistance and cutting performance. HSS inserts, while not as hard as carbide or CBN, offer toughness and are often used in applications where shock resistance is crucial. The choice of material for cutting tool inserts depends on various factors, including the material being machined, the desired surface finish, and the specific requirements of the application. As industries continue to evolve, the demand for cutting tool inserts made from advanced materials is expected to rise, driven by the need for improved performance, efficiency, and cost-effectiveness.

Machinery, Automotive, Aerospace, Energy, Others in the Global Cutting Tool Inserts Market:

The Global Cutting Tool Inserts Market finds extensive usage across various industries, including machinery, automotive, aerospace, energy, and others, each with specific requirements and challenges. In the machinery sector, cutting tool inserts are essential for manufacturing components with high precision and efficiency. They are used in milling, turning, and drilling operations, where accuracy and surface finish are critical. The ability of cutting tool inserts to withstand high temperatures and pressures makes them indispensable in this industry, where downtime can be costly. In the automotive industry, cutting tool inserts play a vital role in the production of engine components, transmission parts, and other critical elements. The demand for lightweight and high-performance vehicles has led to the use of advanced materials, requiring cutting tools that can handle complex machining tasks with precision. Cutting tool inserts enable manufacturers to achieve the desired tolerances and surface finishes, ensuring the quality and reliability of automotive components. The aerospace industry also relies heavily on cutting tool inserts for the production of aircraft components. The need for lightweight and durable materials in aerospace applications necessitates the use of cutting tools that can handle high-strength alloys and composites. Cutting tool inserts provide the precision and efficiency required to meet the stringent quality standards of the aerospace industry. In the energy sector, cutting tool inserts are used in the manufacturing of components for power generation and oil and gas exploration. The harsh environments and demanding conditions in this industry require cutting tools that can withstand extreme temperatures and pressures. Cutting tool inserts offer the durability and performance needed to ensure the reliability and efficiency of energy-related equipment. Beyond these industries, cutting tool inserts are also used in various other applications, including medical device manufacturing, electronics, and construction. The versatility and adaptability of cutting tool inserts make them a valuable asset in any industry that requires precision machining and high-quality components. As industries continue to innovate and evolve, the demand for cutting tool inserts is expected to grow, driven by the need for improved efficiency, performance, and cost-effectiveness.

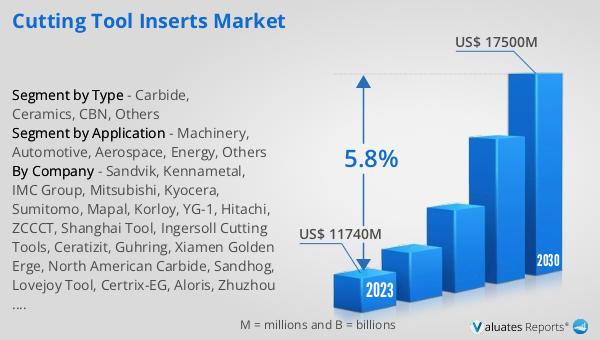

Global Cutting Tool Inserts Market Outlook:

In 2024, the global market size for Cutting Tool Inserts was valued at approximately US$ 13,130 million, with projections indicating a growth to around US$ 19,380 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2025 to 2031. Europe holds the largest share of the Cutting Tool Inserts market, accounting for about 29% of the total market share. Following closely is China, which represents approximately 25% of the market share. The top three companies in this sector collectively occupy about 29% of the market share, highlighting the competitive nature of the industry. The growth in this market is driven by the increasing demand for high-performance cutting tools across various industries, including automotive, aerospace, and energy. As manufacturers seek to enhance productivity and reduce operational costs, the adoption of advanced cutting tool inserts is expected to rise. The market's expansion is also supported by technological advancements and the development of new materials that offer improved performance and durability. With the ongoing industrialization and the need for precision machining, the Global Cutting Tool Inserts Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Cutting Tool Inserts Market |

| CAGR | 5.8% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sandvik, Kennametal, IMC Group, Mitsubishi, Kyocera, Sumitomo, Mapal, Korloy, YG-1, Hitachi, ZCCCT, Shanghai Tool, Ingersoll Cutting Tools, Ceratizit, Guhring, Xiamen Golden Erge, North American Carbide, Sandhog, Lovejoy Tool, Certrix-EG, Aloris, Zhuzhou Cemented Carbide Group, OKE, Zhuzhou Huarui, Beijing Worldia Diamond Tools |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |