What is Global Pleated Membrane Filter Market?

The Global Pleated Membrane Filter Market is a significant segment within the broader filtration industry, focusing on the use of pleated membrane filters for various applications. These filters are designed to remove contaminants from liquids and gases, providing high efficiency and reliability. The market is driven by the increasing demand for clean and safe water, stringent regulations regarding water and wastewater treatment, and the growing need for high-quality filtration in the food and beverage, pharmaceutical, and chemical industries. Pleated membrane filters are preferred due to their large surface area, which allows for higher flow rates and longer service life compared to other types of filters. They are made from various materials, including polypropylene (PP), polyethersulfone (PES), polytetrafluoroethylene (PTFE), and nylon, each offering unique properties suitable for different applications. The market is characterized by technological advancements, product innovations, and strategic collaborations among key players to enhance their product offerings and expand their market presence. As industries continue to prioritize quality and safety, the demand for pleated membrane filters is expected to grow, making it a vital component of the global filtration market.

PP Filter, PES Filter, PTFE Filter, Nylon Filter, Others in the Global Pleated Membrane Filter Market:

Pleated membrane filters are available in various types, each made from different materials, offering distinct advantages and applications. The PP (Polypropylene) filter is widely used due to its chemical resistance and cost-effectiveness. It is suitable for filtering aggressive chemicals and is commonly used in the chemical and water treatment industries. PP filters are known for their durability and ability to handle high temperatures, making them ideal for various industrial applications. The PES (Polyethersulfone) filter is another popular choice, especially in the pharmaceutical and food and beverage industries. PES filters are known for their high flow rates and excellent thermal stability, making them suitable for sterilizing and filtering sensitive liquids. They offer a high degree of purity and are often used in applications where maintaining the integrity of the filtered product is crucial. PTFE (Polytetrafluoroethylene) filters are renowned for their hydrophobic properties, making them ideal for filtering gases and aggressive solvents. They are commonly used in the chemical and pharmaceutical industries for applications requiring high chemical resistance and temperature tolerance. PTFE filters are also used in air filtration systems due to their ability to repel water and resist clogging. Nylon filters are known for their strength and flexibility, making them suitable for a wide range of applications, including water and wastewater treatment, food and beverage processing, and laboratory use. They offer excellent chemical compatibility and are often used in applications where high mechanical strength is required. Other types of pleated membrane filters include those made from materials like cellulose acetate and glass fiber, each offering unique properties for specific applications. These filters are used in various industries, including electronics, biotechnology, and healthcare, where precise filtration is essential. The choice of filter material depends on the specific requirements of the application, including the type of fluid being filtered, the desired flow rate, and the level of filtration needed. As industries continue to evolve and demand higher quality filtration solutions, the development and use of advanced pleated membrane filters are expected to grow, offering enhanced performance and efficiency across various applications.

Food and Beverages, Pharmaceuticals, Water and Wastewater, Chemical, Others in the Global Pleated Membrane Filter Market:

The Global Pleated Membrane Filter Market finds extensive usage across several key industries, each benefiting from the unique properties and capabilities of these filters. In the food and beverage industry, pleated membrane filters are essential for ensuring product quality and safety. They are used to remove impurities, bacteria, and other contaminants from liquids, ensuring that the final product meets stringent health and safety standards. These filters are particularly important in the production of beverages, dairy products, and other consumables where maintaining purity is crucial. In the pharmaceutical industry, pleated membrane filters play a vital role in the production of drugs and other medical products. They are used to sterilize liquids, remove particulates, and ensure that the final product is free from contaminants. The high level of precision and reliability offered by these filters makes them indispensable in pharmaceutical manufacturing, where even the slightest impurity can compromise product efficacy and safety. In the water and wastewater treatment sector, pleated membrane filters are used to remove suspended solids, bacteria, and other impurities from water, ensuring that it is safe for consumption and meets regulatory standards. These filters are crucial in municipal water treatment plants, industrial wastewater treatment facilities, and other applications where clean water is essential. In the chemical industry, pleated membrane filters are used to purify chemicals, remove impurities, and ensure product quality. They are particularly important in processes where high purity levels are required, such as in the production of specialty chemicals and pharmaceuticals. Other industries that utilize pleated membrane filters include electronics, biotechnology, and healthcare, where precise filtration is essential for maintaining product quality and safety. As industries continue to prioritize quality and safety, the demand for pleated membrane filters is expected to grow, making them a vital component of the global filtration market.

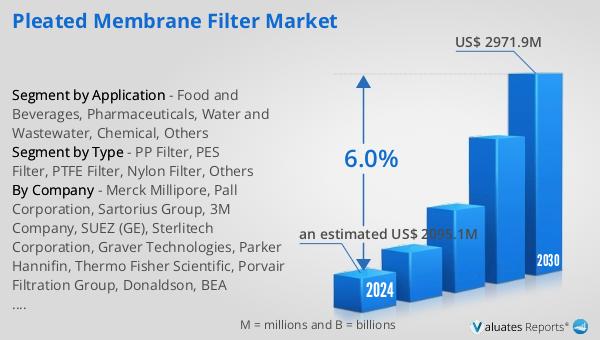

Global Pleated Membrane Filter Market Outlook:

In 2024, the global market size of Pleated Membrane Filters was valued at approximately US$ 2208 million, with projections indicating a growth to around US$ 3301 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold about 45% of the market share. The Asia-Pacific (APAC) region is the largest market, accounting for approximately 50% of the global share, followed by Europe with a 30% share. Among the various types of pleated membrane filters, the PES (Polyethersulfone) filter segment is the largest, holding about 40% of the market share. This dominance is attributed to the PES filter's high flow rates, excellent thermal stability, and suitability for applications in the pharmaceutical and food and beverage industries. The market's growth is driven by increasing demand for high-quality filtration solutions across various industries, including food and beverage, pharmaceuticals, water and wastewater treatment, and chemicals. As industries continue to prioritize quality and safety, the demand for pleated membrane filters is expected to grow, making them a vital component of the global filtration market.

| Report Metric | Details |

| Report Name | Pleated Membrane Filter Market |

| Forecasted market size in 2031 | approximately US$ 3301 million |

| CAGR | 6.0% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Merck Millipore, Pall Corporation, Sartorius Group, 3M Company, SUEZ (GE), Sterlitech Corporation, Graver Technologies, Parker Hannifin, Thermo Fisher Scientific, Porvair Filtration Group, Donaldson, BEA Technologies, Critical Process Filtration, EATON, Fujifilm, Global Filter LLC, Wolftechnik, Cobetter, Pureach, SS Filters |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |