What is Global Towpreg Materials Market?

The Global Towpreg Materials Market refers to the worldwide industry focused on the production and distribution of towpreg materials. Towpregs are pre-impregnated fibers, typically carbon or glass, that are used in various composite manufacturing processes. These materials are pre-coated with a resin system, which can be thermoset or thermoplastic, making them ready for immediate use in manufacturing without the need for additional resin application. The global market for towpreg materials is driven by their increasing application in industries such as automotive, aerospace, defense, sports, and oil and gas. These materials offer significant advantages, including high strength-to-weight ratios, improved durability, and enhanced performance characteristics, which make them ideal for use in high-performance and lightweight structures. The market is characterized by continuous innovation and development, with manufacturers focusing on improving the properties of towpreg materials to meet the evolving demands of various end-use industries.

Epoxy Resin, Phenolic Resin, Others in the Global Towpreg Materials Market:

Epoxy resin, phenolic resin, and other types of resins play a crucial role in the Global Towpreg Materials Market. Epoxy resin is one of the most commonly used resins in towpreg materials due to its excellent mechanical properties, chemical resistance, and strong adhesion capabilities. It is widely used in applications that require high strength and durability, such as aerospace and automotive components. Epoxy resin-based towpregs are known for their ability to withstand harsh environmental conditions and provide long-lasting performance. Phenolic resin, on the other hand, is known for its exceptional fire resistance and low smoke emission properties. This makes it an ideal choice for applications in the aerospace and defense sectors, where safety and fire resistance are of paramount importance. Phenolic resin-based towpregs are also used in the construction of high-temperature-resistant components and structures. Other types of resins used in towpreg materials include polyester, vinyl ester, and thermoplastic resins. These resins offer unique properties that make them suitable for specific applications. For instance, polyester resin is known for its cost-effectiveness and ease of processing, making it a popular choice for mass production of composite parts. Vinyl ester resin offers excellent chemical resistance and is often used in applications that involve exposure to corrosive environments. Thermoplastic resins, such as polypropylene and polyamide, provide advantages such as recyclability and high impact resistance, making them suitable for use in automotive and consumer goods applications. The choice of resin in towpreg materials depends on the specific requirements of the end-use application, including factors such as mechanical performance, environmental resistance, and processing characteristics. Manufacturers in the Global Towpreg Materials Market are continuously exploring new resin formulations and combinations to enhance the performance and versatility of towpreg materials. This ongoing innovation is driven by the need to meet the stringent demands of various industries and to develop materials that can offer superior performance in challenging conditions. The development of advanced resin systems also plays a key role in expanding the application scope of towpreg materials, enabling their use in new and emerging industries. As the market continues to evolve, the focus on resin technology and its impact on the properties of towpreg materials will remain a critical area of research and development.

Automotive & Transporation, Aerospace & Defense, Sports & Recreational, Oil & Gas, Others in the Global Towpreg Materials Market:

The usage of Global Towpreg Materials Market spans across various industries, including automotive and transportation, aerospace and defense, sports and recreational, oil and gas, and others. In the automotive and transportation sector, towpreg materials are used to manufacture lightweight and high-strength components, such as body panels, chassis, and structural parts. The use of towpreg materials helps in reducing the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. In the aerospace and defense industry, towpreg materials are used in the production of aircraft components, such as wings, fuselage, and tail sections. The high strength-to-weight ratio of towpreg materials makes them ideal for use in aerospace applications, where weight reduction is critical for enhancing fuel efficiency and performance. Additionally, the excellent mechanical properties and durability of towpreg materials ensure the reliability and safety of aerospace components. In the sports and recreational sector, towpreg materials are used to manufacture high-performance sporting goods, such as bicycles, golf clubs, tennis rackets, and skis. The lightweight and high-strength properties of towpreg materials enhance the performance and durability of sporting equipment, providing athletes with a competitive edge. In the oil and gas industry, towpreg materials are used in the construction of pipelines, pressure vessels, and other critical infrastructure. The corrosion resistance and high mechanical strength of towpreg materials make them suitable for use in harsh environments, where traditional materials may fail. Other industries that utilize towpreg materials include construction, marine, and wind energy. In the construction industry, towpreg materials are used to manufacture lightweight and durable building components, such as beams, columns, and panels. In the marine industry, towpreg materials are used in the construction of boats, yachts, and other watercraft, providing enhanced performance and durability. In the wind energy sector, towpreg materials are used to manufacture wind turbine blades, which require high strength and stiffness to withstand the forces generated by wind. The versatility and superior properties of towpreg materials make them suitable for a wide range of applications across various industries, driving their demand in the global market.

Global Towpreg Materials Market Outlook:

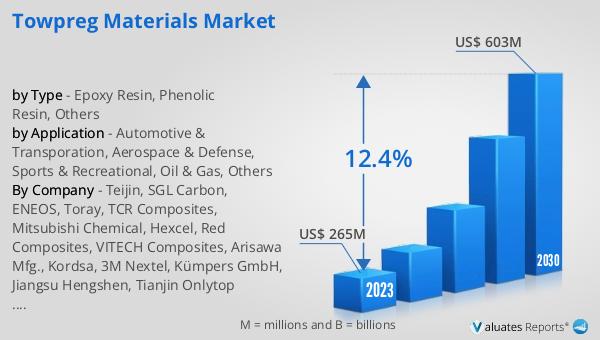

The global Towpreg Materials market was valued at US$ 265 million in 2023 and is anticipated to reach US$ 603 million by 2030, witnessing a CAGR of 12.4% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-performance composite materials across various industries. The market's expansion is driven by the continuous advancements in resin technology and the development of new towpreg formulations that offer enhanced properties and performance. The growing adoption of towpreg materials in the automotive, aerospace, and defense sectors is a key factor contributing to the market's growth. These industries are increasingly focusing on lightweight and high-strength materials to improve fuel efficiency, reduce emissions, and enhance overall performance. Additionally, the rising demand for high-performance sporting goods and the need for durable and corrosion-resistant materials in the oil and gas industry are further propelling the market's growth. The global Towpreg Materials market is characterized by intense competition among key players, who are continuously investing in research and development to innovate and improve their product offerings. The market's growth trajectory is also influenced by the increasing awareness of the benefits of towpreg materials and their expanding application scope in new and emerging industries. As the market continues to evolve, the focus on developing advanced resin systems and enhancing the properties of towpreg materials will remain a critical area of research and development.

| Report Metric | Details |

| Report Name | Towpreg Materials Market |

| Accounted market size in 2023 | US$ 265 million |

| Forecasted market size in 2030 | US$ 603 million |

| CAGR | 12.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teijin, SGL Carbon, ENEOS, Toray, TCR Composites, Mitsubishi Chemical, Hexcel, Red Composites, VITECH Composites, Arisawa Mfg., Kordsa, 3M Nextel, Kümpers GmbH, Jiangsu Hengshen, Tianjin Onlytop High-tech Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |