What is Global Roughness and Contour Measuring Machine Market?

The Global Roughness and Contour Measuring Machine Market is a specialized sector within the broader field of precision measurement technology. These machines are essential tools used in various industries to assess the surface texture and geometric contours of materials and components. By providing accurate measurements of surface roughness and contour, these machines help ensure that products meet stringent quality standards and function as intended. The market for these machines is driven by the increasing demand for high-precision components in industries such as automotive, aerospace, electronics, and manufacturing. As technology advances, the capabilities of these machines continue to improve, offering more detailed and faster measurements. This market is characterized by a mix of established players and new entrants, each striving to offer innovative solutions that cater to the evolving needs of their customers. The global reach of this market is evident, with significant contributions from regions such as Europe and Japan, which are known for their technological advancements and manufacturing prowess. As industries continue to prioritize quality and precision, the demand for roughness and contour measuring machines is expected to grow, making this market a critical component of the global manufacturing landscape.

Contact Roughness and Contour Measuring Machine, Non-Contact Roughness and Contour Measuring Machine in the Global Roughness and Contour Measuring Machine Market:

Contact Roughness and Contour Measuring Machines are integral to the Global Roughness and Contour Measuring Machine Market. These machines utilize a physical probe to make direct contact with the surface being measured. The probe moves across the surface, recording variations in height and contour, which are then translated into precise measurements of surface roughness and geometric features. This method is highly accurate and is particularly useful for measuring hard materials or surfaces with complex geometries. The contact method is favored in industries where precision is paramount, such as aerospace and automotive, where even minor deviations can have significant implications for performance and safety. On the other hand, Non-Contact Roughness and Contour Measuring Machines employ optical or laser-based technologies to assess surface characteristics without physical contact. This approach is advantageous for measuring delicate or soft materials that could be damaged by a contact probe. Non-contact machines are also faster, allowing for rapid assessments of large areas or multiple components. They are increasingly popular in industries like electronics, where the miniaturization of components requires highly detailed and non-invasive measurement techniques. Both contact and non-contact machines have their unique advantages and are chosen based on the specific requirements of the application. The choice between the two often depends on factors such as the material being measured, the required precision, and the speed of measurement. As technology continues to evolve, the capabilities of both contact and non-contact machines are expanding, offering users more options and greater flexibility in their measurement processes. The integration of advanced software and data analysis tools further enhances the functionality of these machines, enabling users to gain deeper insights into their measurements and make more informed decisions. The competition between contact and non-contact technologies drives innovation in the market, leading to the development of hybrid machines that combine the strengths of both methods. These hybrid machines offer the precision of contact measurement with the speed and versatility of non-contact techniques, providing users with a comprehensive solution for their measurement needs. As industries continue to demand higher levels of precision and efficiency, the Global Roughness and Contour Measuring Machine Market is poised for continued growth and innovation.

Automotive, Mechanical Products, Electronic Products, Others in the Global Roughness and Contour Measuring Machine Market:

The Global Roughness and Contour Measuring Machine Market finds extensive application across various industries, each with its unique requirements and challenges. In the automotive industry, these machines are crucial for ensuring the quality and performance of components such as engine parts, transmission systems, and body panels. The precise measurement of surface roughness and contour is essential for optimizing the performance and longevity of these components, as even minor deviations can lead to increased wear and tear or reduced efficiency. In the realm of mechanical products, roughness and contour measuring machines play a vital role in the production of tools, machinery, and equipment. These machines help manufacturers maintain tight tolerances and ensure that their products meet the rigorous standards required for industrial applications. The ability to accurately measure surface characteristics is particularly important in the production of precision tools and machinery, where even the slightest imperfection can impact performance and safety. In the electronics industry, the demand for miniaturized components and high-density circuits necessitates the use of advanced measurement techniques. Non-contact roughness and contour measuring machines are particularly well-suited for this industry, as they can provide detailed measurements of delicate components without causing damage. These machines are used to assess the surface quality of semiconductor wafers, printed circuit boards, and other electronic components, ensuring that they meet the stringent quality standards required for reliable performance. Beyond these primary industries, roughness and contour measuring machines are also used in a variety of other applications, including the production of medical devices, consumer electronics, and aerospace components. In each of these areas, the ability to accurately measure surface characteristics is critical for ensuring product quality and performance. As industries continue to evolve and demand higher levels of precision and efficiency, the Global Roughness and Contour Measuring Machine Market is expected to play an increasingly important role in supporting innovation and quality assurance across a wide range of applications.

Global Roughness and Contour Measuring Machine Market Outlook:

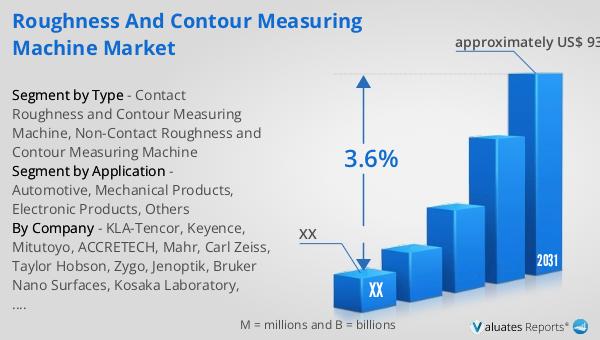

In 2024, the global market size for Roughness and Contour Measuring Machines was valued at approximately US$ 731 million. Projections indicate that by 2031, this market is expected to grow to around US$ 932 million, reflecting a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2025 to 2031. The market is characterized by a concentration of leading manufacturers, with the top five companies collectively holding about 50% of the market share. Europe emerges as the largest regional market, accounting for approximately 35% of the global share, followed closely by Japan, which holds about 30%. In terms of product segmentation, Contact Roughness and Contour Measuring Machines dominate the market, representing roughly 70% of the total share. This dominance is attributed to the high precision and reliability offered by contact measurement methods, which are essential for industries where accuracy is critical. As the market continues to expand, driven by technological advancements and increasing demand for precision measurement solutions, the Global Roughness and Contour Measuring Machine Market is poised for sustained growth and innovation.

| Report Metric | Details |

| Report Name | Roughness and Contour Measuring Machine Market |

| Forecasted market size in 2031 | approximately US$ 932 million |

| CAGR | 3.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | KLA-Tencor, Keyence, Mitutoyo, ACCRETECH, Mahr, Carl Zeiss, Taylor Hobson, Zygo, Jenoptik, Bruker Nano Surfaces, Kosaka Laboratory, Chotest, Alicona, Polytec GmbH, Wale, Guangzhou Wilson |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |