What is Global Automatic Adult Diaper Machine Market?

The Global Automatic Adult Diaper Machine Market refers to the industry that manufactures machines specifically designed to produce adult diapers automatically. These machines are highly sophisticated and can handle various stages of diaper production, including material feeding, cutting, shaping, and packaging. The demand for adult diapers is driven by an aging population, increasing awareness about hygiene, and the rising prevalence of conditions like incontinence. Automatic adult diaper machines are essential for meeting this demand efficiently and cost-effectively. They offer high-speed production capabilities, ensuring that manufacturers can keep up with the growing market needs. Additionally, these machines are designed to produce high-quality diapers that meet stringent health and safety standards. The market for these machines is global, with significant demand in regions like North America, Europe, and Asia-Pacific. Manufacturers are continually innovating to improve the efficiency, speed, and versatility of these machines, making them an indispensable part of the adult diaper production industry.

400-450 PCS/MIN, 500-600 PCS/MIN, Other in the Global Automatic Adult Diaper Machine Market:

In the Global Automatic Adult Diaper Machine Market, machines are categorized based on their production speed, such as 400-450 PCS/MIN, 500-600 PCS/MIN, and other variations. Machines that produce 400-450 pieces per minute are typically used by medium-sized manufacturers who need a balance between speed and cost. These machines are efficient and can produce a significant number of diapers in a short period, making them ideal for companies that are scaling up their production capabilities. On the other hand, machines that produce 500-600 pieces per minute are designed for large-scale manufacturers who require high-speed production to meet massive market demands. These machines are equipped with advanced features like automated quality control, material optimization, and minimal downtime, ensuring that the production process is as efficient as possible. Other variations in production speed cater to specific needs, such as customized production runs or specialized diaper types. These machines offer flexibility and can be adjusted to produce different sizes and types of diapers, including those with unique features like extra absorbency or specialized materials. The choice of machine depends on various factors, including the scale of production, budget, and specific requirements of the manufacturer. Overall, the different production speeds available in the market ensure that manufacturers can choose a machine that best fits their operational needs, thereby optimizing their production process and meeting market demands effectively.

Tape Type, Pants Type in the Global Automatic Adult Diaper Machine Market:

The usage of Global Automatic Adult Diaper Machines is primarily categorized into two types: Tape Type and Pants Type. Tape Type adult diapers are the traditional form of adult diapers that come with adhesive tapes on the sides. These tapes allow for easy adjustment and secure fitting, making them suitable for individuals who require assistance in wearing diapers. Automatic machines designed for Tape Type diapers are equipped with features that ensure precise placement of tapes, high-speed production, and consistent quality. These machines can handle various materials and designs, ensuring that the final product is comfortable, absorbent, and leak-proof. On the other hand, Pants Type adult diapers are designed to be worn like regular underwear, offering greater convenience and discretion. These diapers are popular among active adults who prefer a more natural feel and ease of use. Automatic machines for Pants Type diapers are more complex, as they need to handle the elastic waistband and leg cuffs, ensuring a snug fit without compromising on comfort. These machines are designed to produce high-quality Pants Type diapers at a fast pace, meeting the growing demand for this type of product. Both Tape Type and Pants Type diaper machines play a crucial role in the adult diaper market, catering to different consumer needs and preferences. Manufacturers often invest in both types of machines to diversify their product offerings and capture a larger market share. The advanced technology and automation in these machines ensure that the production process is efficient, cost-effective, and capable of producing high-quality diapers that meet the stringent standards of the healthcare industry.

Global Automatic Adult Diaper Machine Market Outlook:

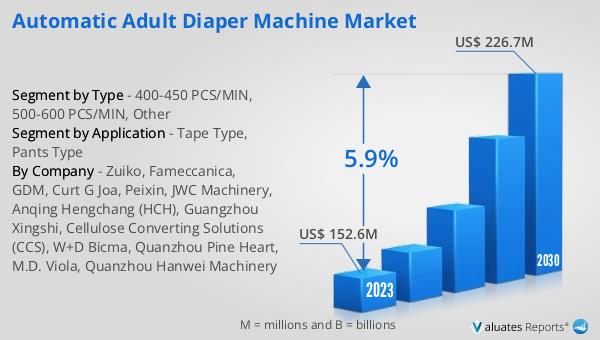

The global Automatic Adult Diaper Machine market was valued at US$ 152.6 million in 2023 and is anticipated to reach US$ 226.7 million by 2030, witnessing a CAGR of 5.9% during the forecast period 2024-2030. This market growth is driven by several factors, including the increasing aging population, rising awareness about hygiene and incontinence issues, and advancements in diaper manufacturing technology. The market is characterized by the presence of several key players who are continually innovating to improve the efficiency, speed, and versatility of automatic adult diaper machines. These machines are essential for meeting the growing demand for adult diapers, ensuring that manufacturers can produce high-quality products at a fast pace. The market is global, with significant demand in regions like North America, Europe, and Asia-Pacific. As the market continues to grow, manufacturers are expected to invest in advanced machinery that offers higher production speeds, better quality control, and greater flexibility in terms of product design and customization. Overall, the global Automatic Adult Diaper Machine market is poised for significant growth, driven by the increasing demand for adult diapers and the continuous advancements in manufacturing technology.

| Report Metric | Details |

| Report Name | Automatic Adult Diaper Machine Market |

| Accounted market size in 2023 | US$ 152.6 million |

| Forecasted market size in 2030 | US$ 226.7 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zuiko, Fameccanica, GDM, Curt G Joa, Peixin, JWC Machinery, Anqing Hengchang (HCH), Guangzhou Xingshi, Cellulose Converting Solutions (CCS), W+D Bicma, Quanzhou Pine Heart, M.D. Viola, Quanzhou Hanwei Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |