What is Global Aerospace Rubber Hose Market?

The Global Aerospace Rubber Hose Market is a specialized segment within the aerospace industry that focuses on the production and distribution of rubber hoses used in various aerospace applications. These hoses are essential components in aircraft systems, providing flexibility and durability in the transfer of fluids and gases under different pressure conditions. The market encompasses a wide range of products, including low-pressure and high-pressure hoses, each designed to meet specific requirements and standards set by the aerospace industry. The demand for aerospace rubber hoses is driven by the need for reliable and high-performance components that can withstand extreme temperatures, pressures, and environmental conditions. These hoses are used in various aircraft systems, such as fuel, hydraulic, and pneumatic systems, ensuring the safe and efficient operation of commercial, general, and military aviation. The market is characterized by continuous innovation and advancements in materials and manufacturing processes to enhance the performance and longevity of rubber hoses. Key players in the market are focused on developing lightweight, high-strength hoses that can meet the stringent requirements of modern aircraft. The global aerospace rubber hose market is expected to grow steadily, driven by the increasing demand for new aircraft and the need for maintenance and replacement of existing hoses.

Low-Pressure Hose, High-Pressure Hose in the Global Aerospace Rubber Hose Market:

Low-pressure hoses and high-pressure hoses are two primary categories within the Global Aerospace Rubber Hose Market, each serving distinct functions and applications in the aerospace industry. Low-pressure hoses are typically used in systems where the pressure does not exceed 300 psi. These hoses are designed to handle the transfer of fluids and gases at relatively low pressures, making them suitable for applications such as fuel lines, coolant lines, and air conditioning systems in aircraft. They are made from materials that provide flexibility, resistance to abrasion, and the ability to withstand varying temperatures. The construction of low-pressure hoses often includes multiple layers of rubber and reinforcement materials to ensure durability and reliability. On the other hand, high-pressure hoses are designed to operate under much higher pressures, often exceeding 3000 psi. These hoses are critical components in hydraulic systems, which are used to control various mechanical functions in aircraft, such as landing gear, brakes, and flight control surfaces. High-pressure hoses must be able to withstand extreme pressure and temperature conditions, as well as resist chemical degradation and mechanical wear. They are typically constructed with multiple layers of high-strength materials, including synthetic rubber, braided steel wire, and other reinforcement materials, to provide the necessary strength and durability. The manufacturing process for high-pressure hoses is more complex and stringent, involving rigorous testing and quality control measures to ensure they meet the high standards required for aerospace applications. Both low-pressure and high-pressure hoses play vital roles in the safe and efficient operation of aircraft. The choice between low-pressure and high-pressure hoses depends on the specific requirements of the application, including the type of fluid or gas being transferred, the operating pressure, and the environmental conditions. In addition to their functional differences, these hoses also vary in terms of maintenance and replacement schedules. High-pressure hoses, due to their critical role and the extreme conditions they operate under, often require more frequent inspections and replacements compared to low-pressure hoses. The development of advanced materials and manufacturing techniques has led to significant improvements in the performance and longevity of both low-pressure and high-pressure hoses. Innovations such as the use of lightweight composite materials and advanced reinforcement techniques have resulted in hoses that are not only stronger and more durable but also lighter, contributing to overall weight reduction in aircraft. This is particularly important in the aerospace industry, where weight savings can lead to improved fuel efficiency and reduced operational costs. The global aerospace rubber hose market continues to evolve, with ongoing research and development efforts aimed at enhancing the performance, reliability, and safety of both low-pressure and high-pressure hoses. Manufacturers are also focusing on developing environmentally friendly hoses that comply with stringent environmental regulations and standards. As the aerospace industry continues to grow and evolve, the demand for high-quality rubber hoses that can meet the diverse and demanding requirements of modern aircraft is expected to remain strong.

Commercial Aviation, General Aviation, Military Aviation in the Global Aerospace Rubber Hose Market:

The usage of rubber hoses in the Global Aerospace Rubber Hose Market spans across various segments of aviation, including commercial aviation, general aviation, and military aviation. In commercial aviation, rubber hoses are integral components in a wide range of aircraft systems, including fuel, hydraulic, and pneumatic systems. These hoses ensure the safe and efficient transfer of fluids and gases, contributing to the overall performance and reliability of commercial aircraft. For instance, fuel hoses are designed to handle the transfer of aviation fuel from storage tanks to the aircraft's engines, while hydraulic hoses are used in systems that control landing gear, brakes, and flight control surfaces. The durability and reliability of these hoses are critical, as any failure could lead to significant safety risks and operational disruptions. In general aviation, which includes private and recreational flying, rubber hoses are used in various aircraft systems to ensure safe and efficient operation. These hoses are often subjected to different operating conditions compared to commercial aviation, including varying altitudes, temperatures, and environmental factors. As such, the materials and construction of rubber hoses used in general aviation must be able to withstand these conditions while providing reliable performance. In military aviation, rubber hoses play a crucial role in the operation of various aircraft systems, including fuel, hydraulic, and pneumatic systems. Military aircraft often operate under extreme conditions, including high speeds, high altitudes, and harsh environments. As a result, the rubber hoses used in military aviation must be able to withstand these conditions while providing reliable performance. In addition to their functional roles, rubber hoses in military aviation must also meet stringent safety and performance standards set by military authorities. The development and production of rubber hoses for military aviation often involve rigorous testing and quality control measures to ensure they meet these standards. The usage of rubber hoses in the Global Aerospace Rubber Hose Market is characterized by continuous innovation and advancements in materials and manufacturing processes. Manufacturers are focused on developing hoses that can meet the diverse and demanding requirements of modern aircraft, including improved performance, durability, and safety. This includes the use of advanced materials, such as lightweight composites and high-strength reinforcement materials, as well as innovative manufacturing techniques that enhance the performance and longevity of rubber hoses. The global aerospace rubber hose market is expected to continue growing, driven by the increasing demand for new aircraft and the need for maintenance and replacement of existing hoses. As the aerospace industry continues to evolve, the demand for high-quality rubber hoses that can meet the diverse and demanding requirements of modern aircraft is expected to remain strong.

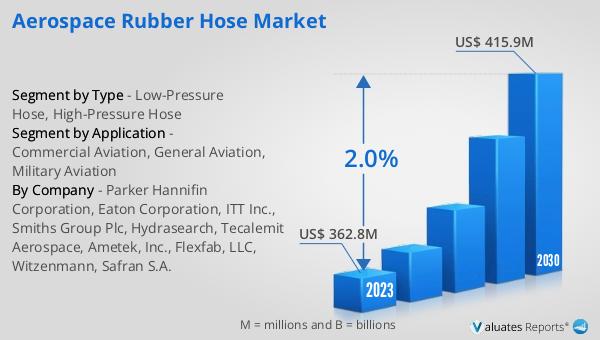

Global Aerospace Rubber Hose Market Outlook:

The global Aerospace Rubber Hose market was valued at US$ 362.8 million in 2023 and is anticipated to reach US$ 415.9 million by 2030, witnessing a CAGR of 2.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the aerospace rubber hose industry, driven by the increasing demand for reliable and high-performance components in various aircraft systems. The market's growth is supported by continuous advancements in materials and manufacturing processes, which enhance the performance and longevity of rubber hoses. Key players in the market are focused on developing lightweight, high-strength hoses that can meet the stringent requirements of modern aircraft. The demand for aerospace rubber hoses is also driven by the need for maintenance and replacement of existing hoses, as well as the increasing production of new aircraft. The market is characterized by a high level of competition, with manufacturers striving to develop innovative products that can meet the diverse and demanding requirements of the aerospace industry. As the aerospace industry continues to grow and evolve, the demand for high-quality rubber hoses is expected to remain strong, contributing to the overall growth of the global aerospace rubber hose market.

| Report Metric | Details |

| Report Name | Aerospace Rubber Hose Market |

| Accounted market size in 2023 | US$ 362.8 million |

| Forecasted market size in 2030 | US$ 415.9 million |

| CAGR | 2.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin Corporation, Eaton Corporation, ITT Inc., Smiths Group Plc, Hydrasearch, Tecalemit Aerospace, Ametek, Inc., Flexfab, LLC, Witzenmann, Safran S.A. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |