What is Global Pharmaceutical Grade Parts Washers Market?

The Global Pharmaceutical Grade Parts Washers Market refers to the specialized segment of the cleaning equipment industry that focuses on providing high-quality, reliable, and efficient washing solutions for parts used in pharmaceutical manufacturing. These washers are designed to meet stringent regulatory standards and ensure that all components are free from contaminants, which is crucial for maintaining the purity and safety of pharmaceutical products. The market encompasses a variety of washer types, including rotary and linear models, each tailored to specific cleaning needs and operational requirements. The demand for these washers is driven by the increasing complexity of pharmaceutical manufacturing processes, the need for compliance with Good Manufacturing Practices (GMP), and the growing emphasis on product quality and safety. As pharmaceutical companies continue to innovate and expand their production capabilities, the need for advanced parts washers that can handle diverse cleaning tasks efficiently and effectively is expected to rise. This market is characterized by continuous technological advancements, with manufacturers focusing on developing more automated, energy-efficient, and user-friendly solutions to meet the evolving needs of the pharmaceutical industry.

Rotary, Linear in the Global Pharmaceutical Grade Parts Washers Market:

Rotary and linear parts washers are two primary types of equipment used in the Global Pharmaceutical Grade Parts Washers Market, each offering unique advantages based on their design and operational mechanisms. Rotary parts washers utilize a rotating drum or basket to clean parts through a combination of mechanical agitation, spray, and immersion. This type of washer is particularly effective for cleaning small to medium-sized parts with complex geometries, as the rotation ensures thorough exposure to cleaning agents and rinsing solutions. The continuous movement helps dislodge contaminants from hard-to-reach areas, making rotary washers ideal for applications where precision and thoroughness are paramount. On the other hand, linear parts washers operate on a conveyor system, where parts are transported through various cleaning stages in a linear fashion. This design is well-suited for high-volume cleaning tasks, as it allows for continuous processing of parts with minimal manual intervention. Linear washers are often used in large-scale pharmaceutical manufacturing facilities where efficiency and throughput are critical. They can be customized with multiple cleaning zones, including pre-wash, wash, rinse, and drying stages, to ensure comprehensive cleaning and drying of parts. Both rotary and linear washers can be equipped with advanced features such as automated controls, real-time monitoring, and data logging to enhance their performance and ensure compliance with regulatory standards. The choice between rotary and linear washers depends on factors such as the size and complexity of the parts to be cleaned, the required cleaning precision, and the production volume. In summary, rotary parts washers offer superior cleaning for intricate parts through rotational agitation, while linear parts washers provide efficient, high-volume cleaning through a conveyor-based system. Both types play a crucial role in maintaining the cleanliness and integrity of pharmaceutical manufacturing components, contributing to the overall quality and safety of pharmaceutical products.

Medical & Pharmaceutical, Bioresearch, Others in the Global Pharmaceutical Grade Parts Washers Market:

The usage of Global Pharmaceutical Grade Parts Washers Market extends across various sectors, including Medical & Pharmaceutical, Bioresearch, and others, each with specific cleaning requirements and standards. In the Medical & Pharmaceutical sector, parts washers are essential for ensuring that all equipment and components used in drug manufacturing are free from contaminants. This includes cleaning of vials, syringes, mixing tanks, and other critical components that come into direct contact with pharmaceutical products. The stringent regulatory environment in this sector necessitates the use of high-quality parts washers that can achieve the required levels of cleanliness and sterility. In Bioresearch, parts washers are used to clean laboratory equipment, glassware, and other instruments that are used in research and development activities. The precision and reliability of these washers are crucial for maintaining the integrity of experimental results and ensuring that no cross-contamination occurs between different research activities. The ability to customize cleaning cycles and parameters is particularly important in this sector, as different types of research may require different cleaning protocols. Other sectors that utilize pharmaceutical grade parts washers include the food and beverage industry, where cleanliness and hygiene are paramount, and the electronics industry, where precision cleaning of components is essential to prevent contamination and ensure product quality. In these sectors, parts washers help maintain high standards of cleanliness and hygiene, contributing to the overall safety and quality of the final products. The versatility and adaptability of pharmaceutical grade parts washers make them valuable assets in various industries, each with its unique set of cleaning challenges and requirements. Overall, the usage of these washers in different sectors underscores their importance in maintaining cleanliness, safety, and quality across a wide range of applications.

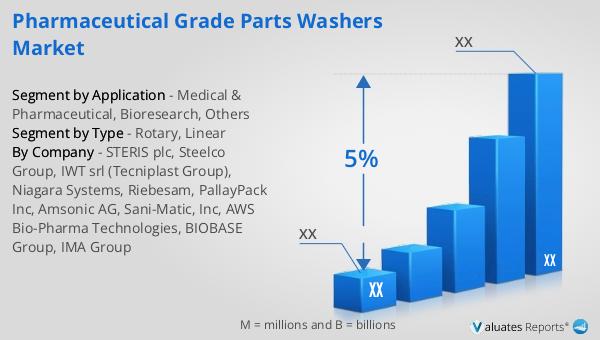

Global Pharmaceutical Grade Parts Washers Market Outlook:

The global pharmaceutical market was valued at 1475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market saw an increase from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth trajectory highlights the expanding demand for pharmaceutical products and the corresponding need for high-quality manufacturing processes, including the use of pharmaceutical grade parts washers. As the pharmaceutical industry continues to grow, the importance of maintaining stringent cleanliness standards becomes even more critical. Parts washers play a vital role in ensuring that all components used in drug manufacturing are free from contaminants, thereby safeguarding the quality and safety of pharmaceutical products. The increasing complexity of pharmaceutical manufacturing processes and the growing emphasis on compliance with regulatory standards further drive the demand for advanced parts washers. These washers are designed to meet the specific needs of the pharmaceutical industry, offering features such as automated controls, real-time monitoring, and data logging to enhance their performance and ensure compliance with Good Manufacturing Practices (GMP). The continuous technological advancements in parts washer design and functionality reflect the industry's commitment to maintaining high standards of cleanliness and quality. As pharmaceutical companies continue to innovate and expand their production capabilities, the need for reliable and efficient parts washers is expected to rise, contributing to the overall growth of the Global Pharmaceutical Grade Parts Washers Market.

| Report Metric | Details |

| Report Name | Pharmaceutical Grade Parts Washers Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | STERIS plc, Steelco Group, IWT srl (Tecniplast Group), Niagara Systems, Riebesam, PallayPack Inc, Amsonic AG, Sani-Matic, Inc, AWS Bio-Pharma Technologies, BIOBASE Group, IMA Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |