What is Global Precision Link Conveyor Market?

The Global Precision Link Conveyor Market is a specialized segment within the broader conveyor systems industry, focusing on high-precision and high-speed applications. Precision link conveyors are designed to provide accurate and repeatable positioning of products, making them ideal for industries that require meticulous assembly and processing. These conveyors are often used in automated manufacturing environments where precision and efficiency are paramount. They are engineered to handle a variety of tasks, from simple transportation to complex assembly operations, with minimal deviation in positioning. The market for precision link conveyors is driven by the increasing demand for automation in manufacturing processes, as companies seek to improve productivity and reduce labor costs. Additionally, advancements in technology have led to the development of more sophisticated conveyor systems that can handle a wider range of products with greater accuracy. As industries continue to evolve and adopt more automated solutions, the demand for precision link conveyors is expected to grow, offering opportunities for manufacturers and suppliers in this niche market. The market is characterized by a mix of established players and new entrants, each vying to offer innovative solutions that meet the specific needs of their customers.

PLC Pallet Type, PBC Belt Type, Others in the Global Precision Link Conveyor Market:

In the Global Precision Link Conveyor Market, there are several types of conveyors that cater to different industrial needs, including the PLC Pallet Type, PBC Belt Type, and others. The PLC Pallet Type conveyors are designed for applications that require precise positioning and handling of products on pallets. These conveyors are often used in industries such as automotive and electronics, where components need to be accurately positioned for assembly or inspection. The PLC Pallet Type conveyors are known for their durability and ability to handle heavy loads, making them suitable for demanding environments. They are equipped with advanced control systems that allow for precise movement and positioning of pallets, ensuring that products are handled with care and accuracy. On the other hand, the PBC Belt Type conveyors are designed for applications that require continuous movement of products along a belt. These conveyors are commonly used in industries such as food and beverage, pharmaceuticals, and packaging, where products need to be transported quickly and efficiently. The PBC Belt Type conveyors are known for their versatility and ability to handle a wide range of products, from small items to large packages. They are equipped with features such as adjustable speed controls and customizable belt configurations, allowing them to be tailored to specific application needs. In addition to the PLC Pallet Type and PBC Belt Type conveyors, there are other types of precision link conveyors that cater to niche applications. These include conveyors designed for cleanroom environments, where contamination control is critical, and conveyors that are designed for high-temperature or corrosive environments. Each type of conveyor offers unique features and benefits, making them suitable for specific industrial applications. As the demand for automation and precision in manufacturing processes continues to grow, the market for precision link conveyors is expected to expand, offering opportunities for manufacturers to develop innovative solutions that meet the evolving needs of their customers.

Automotive, Electronic, Medical & Pharmaeutical, Telecommunicaton, Others in the Global Precision Link Conveyor Market:

The Global Precision Link Conveyor Market finds extensive usage across various industries, including automotive, electronics, medical and pharmaceutical, telecommunications, and others. In the automotive industry, precision link conveyors are used for assembling components such as engines, transmissions, and other critical parts. These conveyors provide the accuracy and repeatability needed to ensure that each component is assembled to exact specifications, reducing the risk of defects and improving overall product quality. In the electronics industry, precision link conveyors are used for assembling and testing electronic components, such as circuit boards and semiconductor devices. The conveyors' ability to handle delicate components with precision and care makes them ideal for this industry, where even the slightest deviation can result in product failure. In the medical and pharmaceutical industries, precision link conveyors are used for assembling and packaging medical devices and pharmaceutical products. These conveyors are designed to meet strict hygiene and contamination control standards, ensuring that products are handled safely and efficiently. In the telecommunications industry, precision link conveyors are used for assembling and testing communication devices, such as smartphones and network equipment. The conveyors' ability to handle complex assembly tasks with precision and speed makes them an essential tool in this fast-paced industry. Beyond these industries, precision link conveyors are also used in other sectors, such as food and beverage, packaging, and consumer goods, where precision and efficiency are critical to success. As industries continue to evolve and adopt more automated solutions, the demand for precision link conveyors is expected to grow, offering opportunities for manufacturers and suppliers to develop innovative solutions that meet the specific needs of their customers.

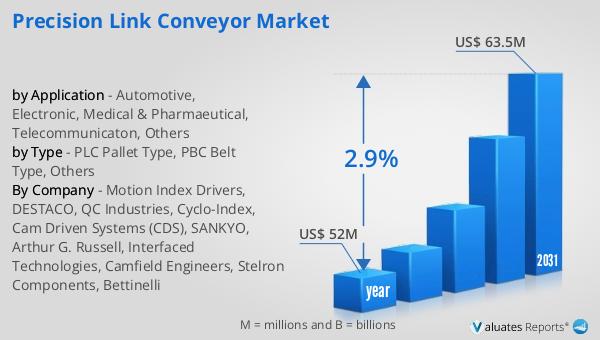

Global Precision Link Conveyor Market Outlook:

The global market for Precision Link Conveyor was valued at $52 million in 2024 and is anticipated to expand to a revised size of $63.5 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% over the forecast period. North America stands out as the largest market, holding a share exceeding 40%. This growth trajectory underscores the increasing demand for precision link conveyors across various industries, driven by the need for automation and efficiency in manufacturing processes. The market's expansion is fueled by technological advancements that have enhanced the capabilities of precision link conveyors, enabling them to handle a wider range of applications with greater accuracy and reliability. As industries continue to embrace automation to improve productivity and reduce labor costs, the demand for precision link conveyors is expected to rise, offering significant opportunities for manufacturers and suppliers in this niche market. The North American market's dominance can be attributed to the region's strong industrial base and the presence of key players in the precision link conveyor industry. As the market continues to evolve, companies are likely to focus on developing innovative solutions that cater to the specific needs of their customers, ensuring sustained growth and competitiveness in the global market.

| Report Metric | Details |

| Report Name | Precision Link Conveyor Market |

| Accounted market size in year | US$ 52 million |

| Forecasted market size in 2031 | US$ 63.5 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Motion Index Drivers, DESTACO, QC Industries, Cyclo-Index, Cam Driven Systems (CDS), SANKYO, Arthur G. Russell, Interfaced Technologies, Camfield Engineers, Stelron Components, Bettinelli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |