What is Global Modular Gripper Systems Market?

The Global Modular Gripper Systems Market is a dynamic and evolving sector within the industrial automation landscape. Modular gripper systems are essential components in robotic and automation applications, designed to handle, manipulate, and transport various objects with precision and efficiency. These systems are characterized by their modularity, allowing for customization and adaptability to different tasks and environments. They are widely used across industries such as automotive, electronics, food and beverage, and more, where automation is crucial for enhancing productivity and reducing operational costs. The market is driven by the increasing demand for automation solutions, advancements in robotic technologies, and the need for flexible manufacturing processes. As industries continue to embrace automation, the demand for modular gripper systems is expected to grow, offering opportunities for innovation and development in this field. The market's growth is also supported by the rising trend of Industry 4.0, which emphasizes smart manufacturing and the integration of advanced technologies into production processes. Overall, the Global Modular Gripper Systems Market plays a vital role in the automation ecosystem, contributing to the efficiency and effectiveness of modern manufacturing and production operations.

Parallel Gripper Systems, Angular Gripper Systems in the Global Modular Gripper Systems Market:

Parallel gripper systems and angular gripper systems are two prominent types of grippers within the Global Modular Gripper Systems Market, each serving distinct purposes and applications. Parallel gripper systems are designed to open and close in a parallel motion, making them ideal for handling objects with uniform shapes and sizes. These grippers are commonly used in applications where precision and repeatability are crucial, such as in the electronics and electrical industries. They are capable of handling delicate components without causing damage, thanks to their precise control and gentle gripping force. Parallel grippers are also favored in the automotive manufacturing sector, where they are used to handle parts and components during assembly processes. Their ability to maintain a consistent grip on objects makes them suitable for high-speed operations, contributing to increased productivity and efficiency in manufacturing environments. On the other hand, angular gripper systems operate by opening and closing in an angular motion, resembling the movement of a human hand. This design allows them to handle objects with irregular shapes and sizes, making them versatile for a wide range of applications. Angular grippers are often used in industries where flexibility and adaptability are essential, such as in the food and beverage sector. They can easily adjust to different product shapes and sizes, ensuring efficient handling and packaging processes. Additionally, angular grippers are utilized in the metal products industry, where they are employed to handle heavy and bulky items with ease. Their robust construction and ability to exert significant gripping force make them suitable for demanding applications that require strength and durability. Both parallel and angular gripper systems are integral to the Global Modular Gripper Systems Market, offering unique advantages and capabilities that cater to the diverse needs of various industries. As automation continues to advance, the demand for these gripper systems is expected to rise, driven by the need for efficient and flexible handling solutions in modern manufacturing and production environments.

Automotive Manufacturing, Electonics & Electrical, Metal Products, Food & Beverage, Rubber & Plastics, Others in the Global Modular Gripper Systems Market:

The Global Modular Gripper Systems Market finds extensive usage across various industries, each benefiting from the unique capabilities and advantages offered by these systems. In the automotive manufacturing sector, modular gripper systems are employed to handle and assemble various components, enhancing the efficiency and precision of production processes. These systems enable the automation of repetitive tasks, reducing the reliance on manual labor and minimizing the risk of errors. In the electronics and electrical industry, modular gripper systems are used to handle delicate components and assemblies, ensuring precision and accuracy in the manufacturing process. Their ability to handle small and intricate parts without causing damage is crucial in maintaining the quality and reliability of electronic products. In the metal products industry, modular gripper systems are utilized to handle heavy and bulky items, streamlining the production process and improving overall efficiency. These systems are designed to withstand the demanding conditions of metalworking environments, providing reliable and durable performance. In the food and beverage sector, modular gripper systems are used to handle and package various products, ensuring hygiene and safety standards are met. Their adaptability to different product shapes and sizes makes them ideal for handling a wide range of food and beverage items. In the rubber and plastics industry, modular gripper systems are employed to handle and assemble components, improving the efficiency and precision of production processes. These systems are designed to handle the unique properties of rubber and plastic materials, ensuring reliable and consistent performance. Additionally, modular gripper systems are used in other industries, such as pharmaceuticals and logistics, where automation and precision are essential for efficient operations. Overall, the Global Modular Gripper Systems Market plays a crucial role in enhancing the efficiency and effectiveness of various industries, contributing to the advancement of automation and manufacturing technologies.

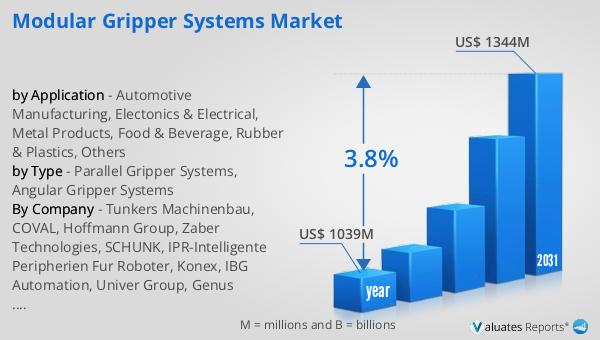

Global Modular Gripper Systems Market Outlook:

The global market for Modular Gripper Systems was valued at US$ 1039 million in the year 2024 and is projected to reach a revised size of US$ 1344 million by 2031, growing at a CAGR of 3.8% during the forecast period. This growth reflects the increasing demand for automation solutions across various industries, driven by the need for enhanced productivity and efficiency. As industries continue to embrace automation and advanced manufacturing technologies, the demand for modular gripper systems is expected to rise. These systems offer flexibility, precision, and adaptability, making them ideal for a wide range of applications. The market's growth is also supported by the rising trend of Industry 4.0, which emphasizes smart manufacturing and the integration of advanced technologies into production processes. As a result, the Global Modular Gripper Systems Market is poised for significant growth, offering opportunities for innovation and development in this field. The market's expansion is further fueled by the increasing adoption of robotics and automation in various industries, as companies seek to improve their operational efficiency and reduce costs. Overall, the Global Modular Gripper Systems Market is set to experience steady growth in the coming years, driven by the increasing demand for automation solutions and the continued advancement of manufacturing technologies.

| Report Metric | Details |

| Report Name | Modular Gripper Systems Market |

| Accounted market size in year | US$ 1039 million |

| Forecasted market size in 2031 | US$ 1344 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tunkers Machinenbau, COVAL, Hoffmann Group, Zaber Technologies, SCHUNK, IPR-Intelligente Peripherien Fur Roboter, Konex, IBG Automation, Univer Group, Genus Technologies, SAS Atomation, Schmalz, GIMATIC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |