What is Global Niobium Alloy Powder for 3D Printing Market?

Global Niobium Alloy Powder for 3D Printing Market is a specialized segment within the broader 3D printing industry, focusing on the use of niobium alloy powders as a material for additive manufacturing. Niobium is a rare, ductile metal known for its high melting point, corrosion resistance, and superconducting properties. These characteristics make it an ideal candidate for creating high-performance components in various industries. In the context of 3D printing, niobium alloy powders are used to produce complex, lightweight structures that are difficult to achieve with traditional manufacturing methods. The market for these powders is driven by the growing demand for advanced materials that can withstand extreme conditions, such as high temperatures and corrosive environments. As industries like aerospace, automotive, and medical devices increasingly adopt 3D printing technologies, the demand for niobium alloy powders is expected to rise. This market is characterized by ongoing research and development efforts aimed at improving the properties of niobium alloys and expanding their applications. Companies operating in this space are investing in innovative technologies to enhance the quality and performance of their products, thereby gaining a competitive edge in the market.

Niobium Titanium Alloy, Niobium Titanium Aluminum Alloy, Others in the Global Niobium Alloy Powder for 3D Printing Market:

Niobium Titanium Alloy, Niobium Titanium Aluminum Alloy, and other niobium-based alloys are pivotal in the Global Niobium Alloy Powder for 3D Printing Market. Niobium Titanium Alloy is a blend of niobium and titanium, known for its excellent superconducting properties. This alloy is primarily used in applications that require high magnetic fields, such as MRI machines and particle accelerators. Its ability to maintain superconductivity at relatively high temperatures makes it a valuable material in the field of medical imaging and scientific research. The alloy's strength and resistance to corrosion also make it suitable for aerospace and automotive applications, where durability and performance are critical. On the other hand, Niobium Titanium Aluminum Alloy incorporates aluminum into the mix, enhancing the alloy's strength and thermal stability. This combination is particularly beneficial in high-temperature environments, such as jet engines and gas turbines, where materials are subjected to extreme heat and stress. The addition of aluminum not only improves the alloy's mechanical properties but also reduces its weight, making it an attractive option for industries focused on fuel efficiency and weight reduction. Other niobium-based alloys in the market include those combined with elements like zirconium and hafnium, each offering unique properties tailored to specific applications. For instance, Niobium Zirconium Alloy is known for its excellent corrosion resistance and is often used in chemical processing equipment and nuclear reactors. Meanwhile, Niobium Hafnium Alloy is prized for its high melting point and is used in applications that require materials to withstand extreme temperatures, such as rocket nozzles and heat shields. The versatility of niobium alloys in 3D printing lies in their ability to be customized to meet the specific needs of different industries. By adjusting the composition of the alloy, manufacturers can create materials that offer the perfect balance of strength, weight, and resistance to environmental factors. This flexibility is a significant advantage in the rapidly evolving field of additive manufacturing, where the demand for specialized materials is continually growing. As research and development efforts continue to advance the capabilities of niobium alloys, their role in the 3D printing market is expected to expand, offering new opportunities for innovation and growth.

Aerospace, Industrial Mold, Vehicle, Medical Instruments, Military, Others in the Global Niobium Alloy Powder for 3D Printing Market:

The usage of Global Niobium Alloy Powder for 3D Printing Market spans several critical areas, including aerospace, industrial mold, vehicle manufacturing, medical instruments, military applications, and others. In the aerospace sector, niobium alloy powders are used to produce lightweight, high-strength components that can withstand the extreme conditions of flight. The ability to create complex geometries with 3D printing allows for the optimization of parts, reducing weight and improving fuel efficiency. This is particularly important in the aerospace industry, where even small reductions in weight can lead to significant cost savings and environmental benefits. In the realm of industrial mold making, niobium alloy powders offer the advantage of producing molds with intricate designs and superior durability. The high melting point and corrosion resistance of niobium alloys ensure that molds can withstand the rigors of repeated use, making them ideal for mass production processes. In vehicle manufacturing, the use of niobium alloy powders in 3D printing allows for the creation of lightweight, high-performance parts that contribute to improved fuel efficiency and reduced emissions. The automotive industry is increasingly turning to additive manufacturing to produce components that are not only lighter but also stronger and more durable than those made with traditional methods. In the medical field, niobium alloy powders are used to create custom implants and surgical instruments that require biocompatibility and precision. The ability to produce patient-specific implants with 3D printing technology enhances the effectiveness of medical treatments and improves patient outcomes. Military applications of niobium alloy powders include the production of lightweight armor and high-strength components for vehicles and equipment. The unique properties of niobium alloys, such as their resistance to corrosion and high temperatures, make them suitable for use in harsh environments and demanding conditions. Other areas where niobium alloy powders are utilized include the production of consumer electronics, where the need for miniaturization and performance drives the demand for advanced materials. As the capabilities of 3D printing continue to evolve, the potential applications for niobium alloy powders are expected to expand, offering new opportunities for innovation across various industries.

Global Niobium Alloy Powder for 3D Printing Market Outlook:

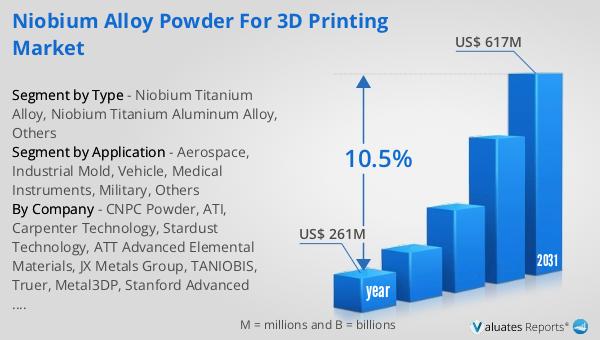

The global market for Niobium Alloy Powder for 3D Printing was valued at $261 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $617 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 10.5% over the forecast period. The increasing demand for advanced materials in various industries, such as aerospace, automotive, and medical devices, is a key driver of this market expansion. As these industries continue to adopt 3D printing technologies, the need for high-performance materials like niobium alloy powders is expected to rise. The unique properties of niobium alloys, including their high melting point, corrosion resistance, and superconducting capabilities, make them ideal for creating complex, lightweight structures that are difficult to achieve with traditional manufacturing methods. Companies operating in this market are investing in research and development to enhance the quality and performance of their products, thereby gaining a competitive edge. The ongoing advancements in 3D printing technology and the increasing focus on sustainability and efficiency are likely to further fuel the growth of the niobium alloy powder market in the coming years.

| Report Metric | Details |

| Report Name | Niobium Alloy Powder for 3D Printing Market |

| Accounted market size in year | US$ 261 million |

| Forecasted market size in 2031 | US$ 617 million |

| CAGR | 10.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CNPC Powder, ATI, Carpenter Technology, Stardust Technology, ATT Advanced Elemental Materials, JX Metals Group, TANIOBIS, Truer, Metal3DP, Stanford Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |